Aircraft engine cleaning solution filtering and recycling vehicle with self-contained lifting device

A technology of aircraft engine and lifting device, which is applied in the direction of filtration treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of lack of such devices, and achieve the effects of saving resources, facilitating adjustment, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

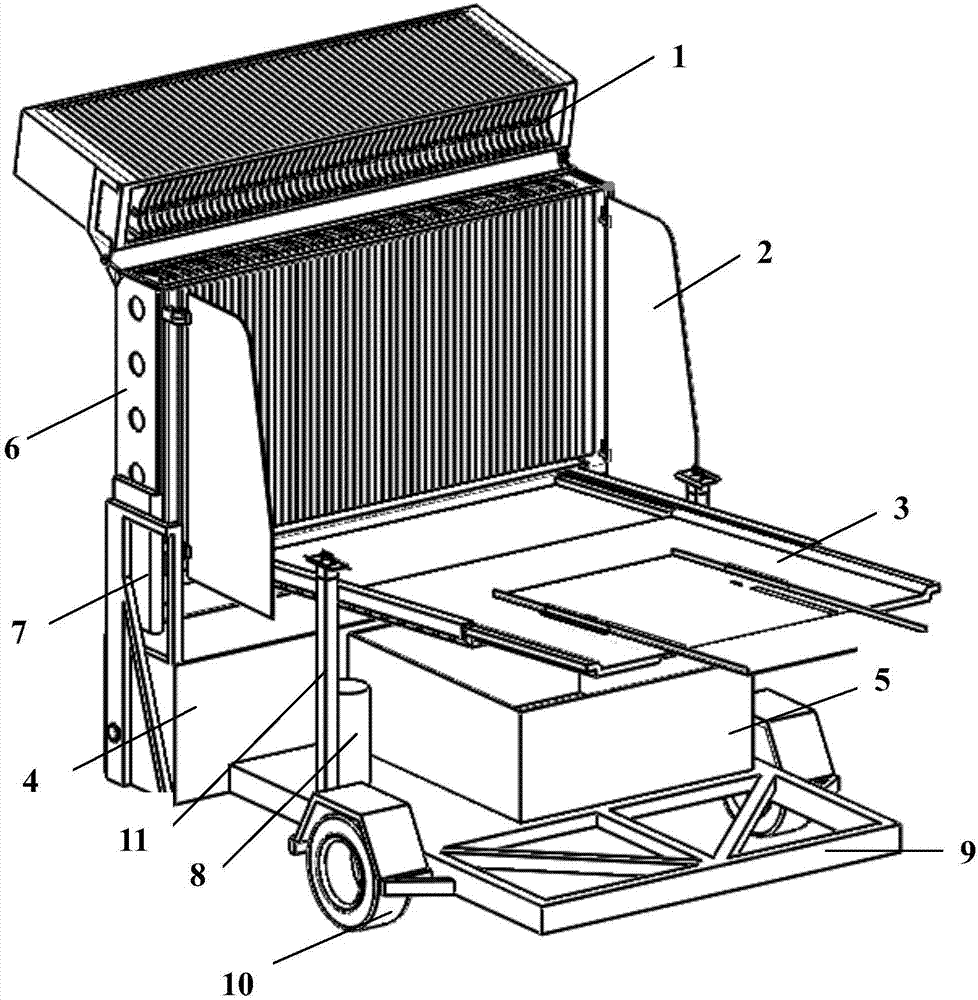

[0010] The aircraft engine cleaning fluid filtration and recovery vehicle with its own lifting device provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0011] Such as figure 1 As shown, the aircraft engine cleaning liquid filtration and recovery vehicle with lifting device provided by the present invention includes a metal grid 1, a baffle plate 2, a collecting plate 3, a water collection tank 4, a clean water tank 5, a lifting support frame 6, a lifting system 7, Filtration device 8, chassis 9, wheels 10, and support rods 11; wherein chassis 9 is arranged horizontally; a plurality of wheels 10 are installed in the front and rear parts of both sides of chassis 9 in a rotational manner; water collection tank 4 is arranged on the rear surface of chassis 9, The upper end is formed with an opening; the lifting system 7 is arranged on the rear side above the opening of the water collection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com