Guide folding die for high speed sewing machine

A mechanical, high-speed technology, applied in sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of high technical requirements, low efficiency, inability to sew collars, etc., to achieve good operation safety, improve work efficiency, and simple operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

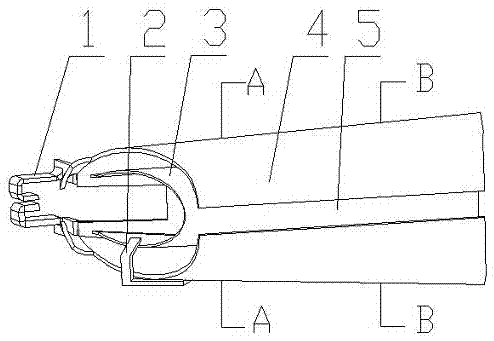

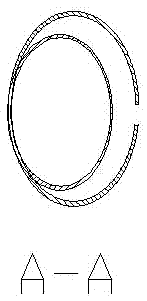

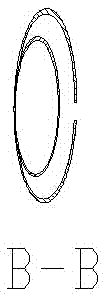

[0026] See attached figure 1 , 2 , 3, the high-speed sewing machine shown in the embodiment of the present invention is used guide folding mold, is made up of outer material guide cylinder 4, inner material guide cylinder 3, two nozzle bending bends 1, pressure plate 3, inner material guide The barrel 3 is set in the outer guide barrel 4 and is biased to the side of the outer guide barrel 4. The two are fixedly connected. The outer guide barrel is provided with a feed groove 5, and two nozzle bending bends 1 are symmetrically connected to the outer guide barrel. On the side of the outlet end of the material guide cylinder, the nozzle bend is a U-shaped component, and the angle between the nozzle bend and the center line of the inner guide cylinder is 30° 0 , it also includes a pressure plate 2 fixedly installed at the outlet of the outer material guide cylinder and the inner material guide cylinder.

[0027] When the present invention is in use, the material is inserted thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com