Construction method of large-diameter precipitation well in subway mined tunnel

A construction method and technology of dewatering wells, which are applied in tunnels, earthwork drilling, mining equipment, etc., and can solve problems affecting the construction of underground excavation projects and water seepage at the excavation face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

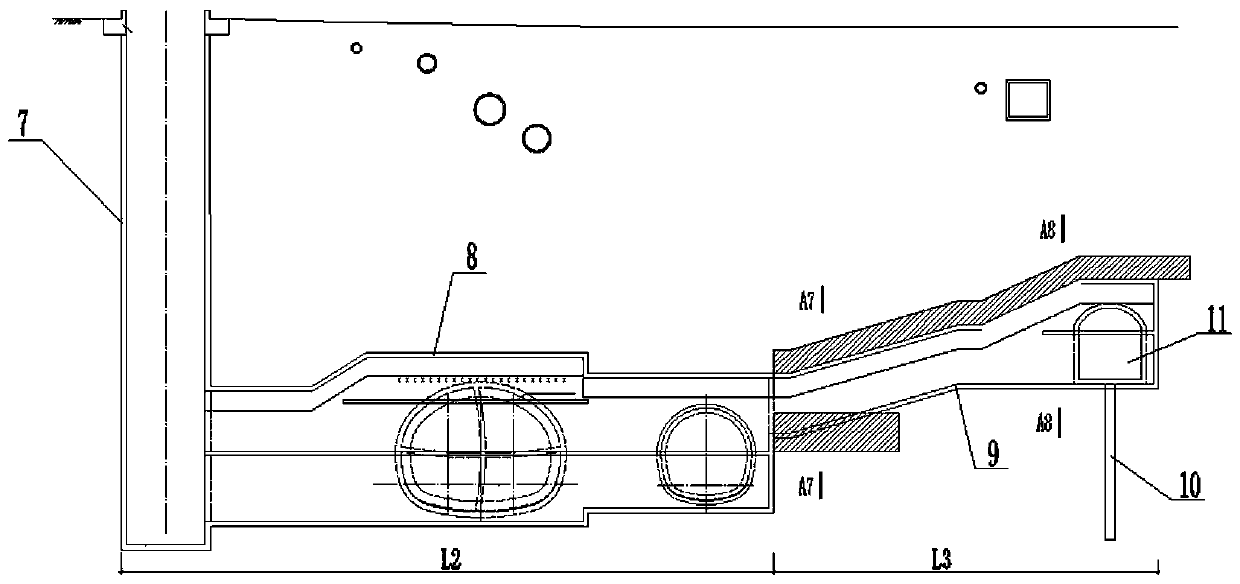

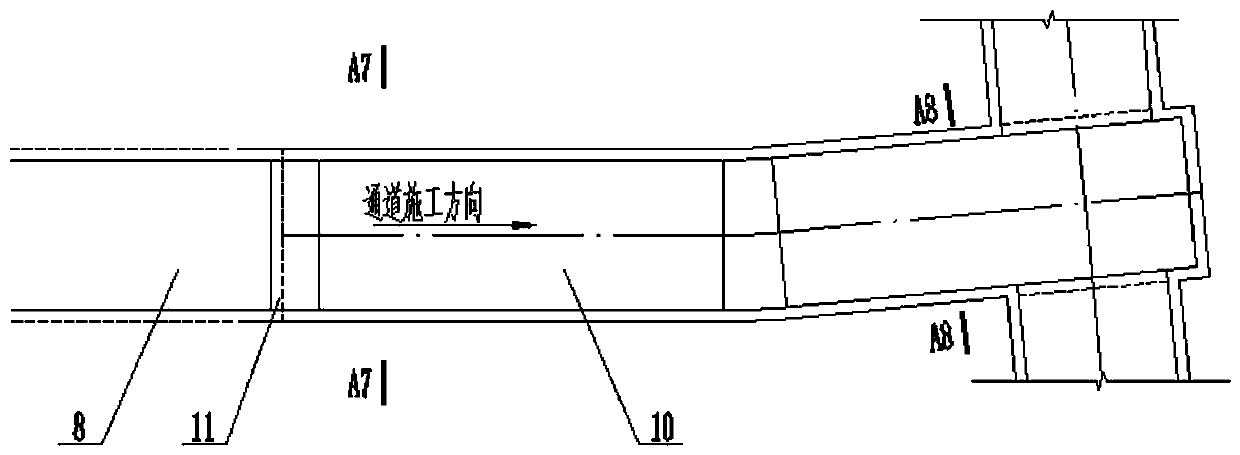

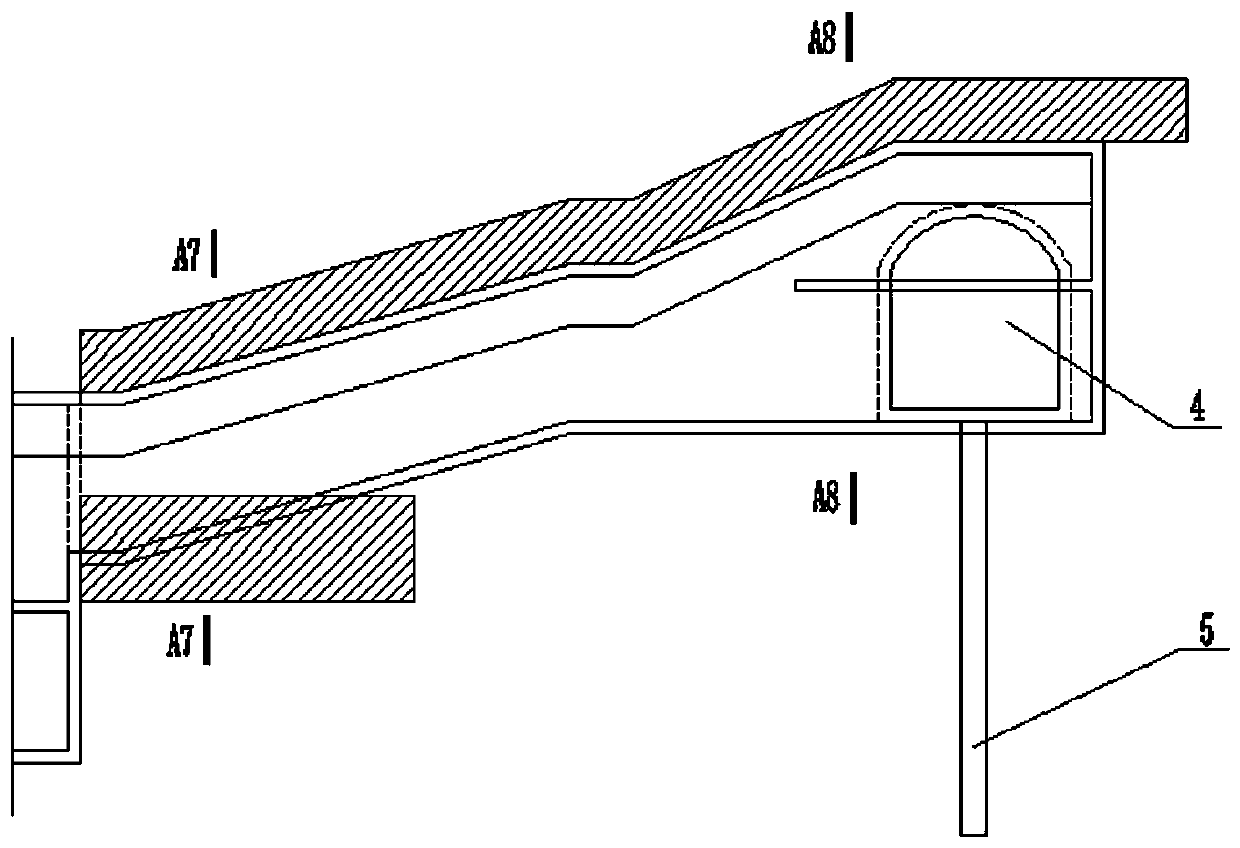

[0028] Taking the subway construction in the interval from Ganjiakou Station to Yuyuantan Dongmen Station as an example, the specific implementation of the present invention will be further described:

[0029] 1. Project introduction

[0030] The section from Ganjiakou Station to Yuyuantan Dongmen Station has a total length of 705.6 meters. The standard section of the left line of the section is a single-hole, double-line section, and the standard section of the right line is a single-hole, single-line section. Different types of cross-sections are excavated by step method, CRD method and double side wall pilot pit method respectively. The strata that the interval tunnel crosses are mainly sandy pebbles, conglomerate, and silt fine sand, and there is a layer of interlayer water within the excavation range. The design uses tube wells for dewatering, and a row of tube wells with a diameter of 273mm and a pipe diameter of 200mm are installed on both sides of the tunnel for dewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com