Hopper device of fluidized drying machine enabling users to take materials at any time

A technology of boiling dryer and hopper device, used in drying solid materials, heating to dry solid materials, dryers, etc., can solve the problem that the drying time is up, the materials do not meet the drying requirements, and the drying conditions of the materials cannot be grasped at any time. problems, to achieve the effect of ensuring drying quality, reducing waste, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

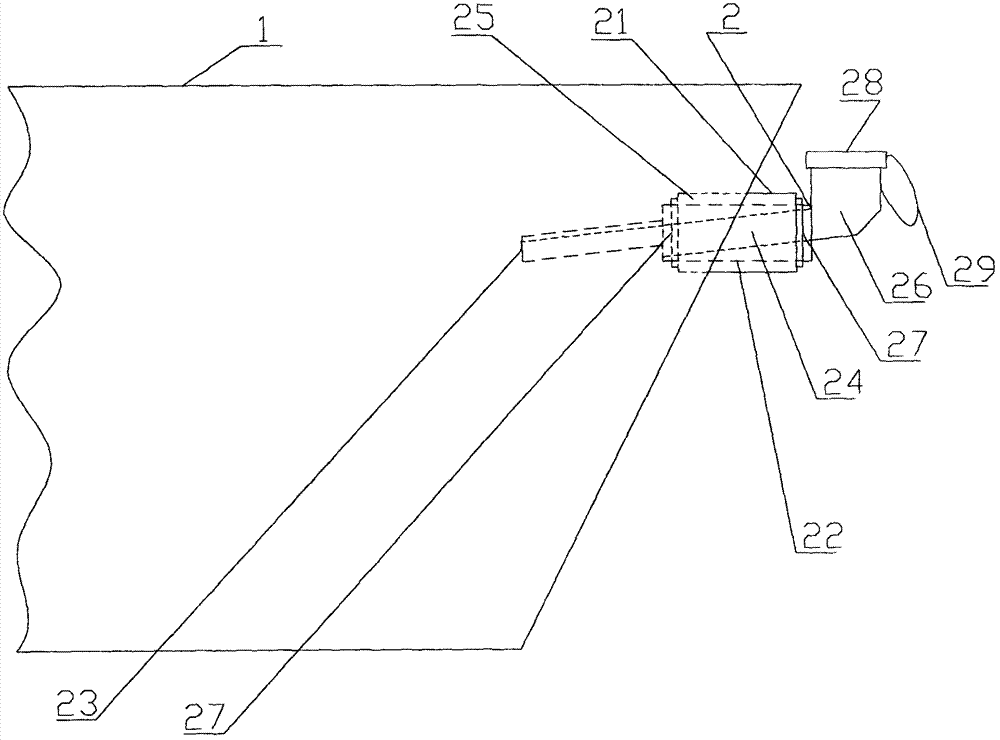

[0015] refer to figure 1 , a hopper device that can be retrieved at any time for a fluidized dryer in the present invention, comprising a hopper 1 and a reclaiming mechanism 2, the rear wall of the hopper 1 is provided with a reclaiming mechanism 2, and the reclaiming mechanism 2 includes a casing 21. Shaft body 22, material receiving trough 23, material channel 24, rubber sleeve 25 and hopper 26, the rear wall of the hopper 1 is provided with a fixedly connected sleeve body 21, and the sleeve body 21 is provided with A rubber sleeve 25, the rubber sleeve 25 is provided with a shaft body 22, the shaft body 22 is provided with a material channel 24 with a low front end and a high rear end, the rear end of the shaft body 22 is provided with a hopper 26, the The discharge port of the hopper 26 communicates with the material channel 24, the front end of the shaft body 22 is provided with a material receiving tank 23 with a low front and a high rear, and the rear end of the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com