Pellet shaft furnace waste heat comprehensive recovery device

A waste heat recovery device and technology of recovery device, applied in furnaces, furnace components, waste heat treatment, etc., can solve the problems of small steam production, poor system stability, small thermal inertia, etc., and achieve sufficient recovery of waste heat, system stability, thermal inertia, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

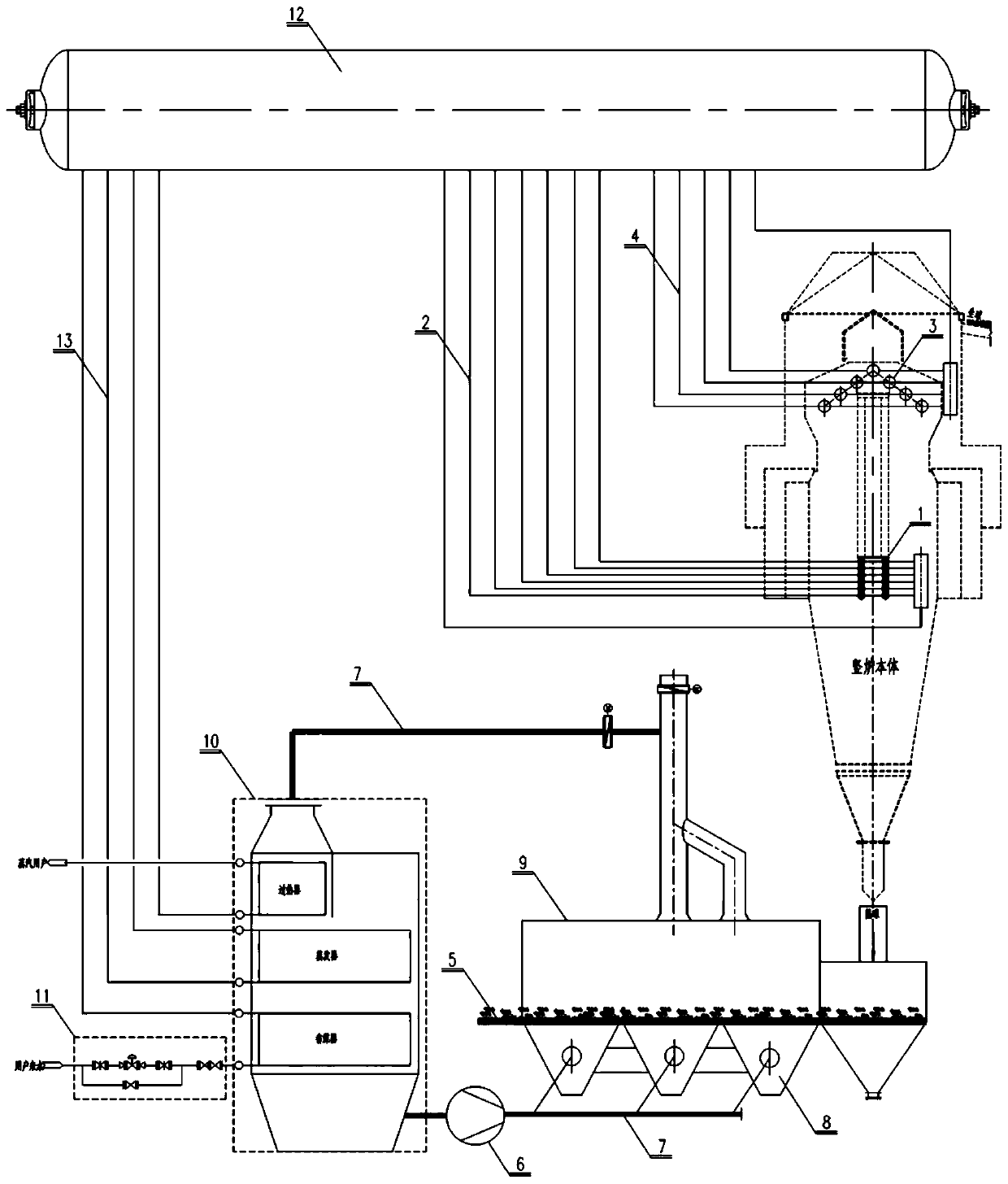

[0036] see figure 1 As shown, the present invention provides a comprehensive recovery device for waste heat of a pelletizing shaft furnace, which includes a waste heat recovery device for cooked pellets with a cooler and a steam-water separation device 12, and the device for recovering waste heat with a cooler for cooked pellets includes a heat exchange device 10; The heat exchange device 10 includes a box body and a superheater, an evaporator and an economizer arranged sequentially in the box along the flow direction of the flue gas;

[0037] Wherein, the water outlet and water inlet of the economizer communicate with the steam-water separator 12 and the water supply pipeline through pipelines respectively; the water outlet and water inlet of the evaporator communicate with the water inlet and water outlet of the steam-water separator 12 through pipelines respectively; The steam outlet and steam inlet of the superheater communicate with the steam outlet of the steam-water sep...

Embodiment 2

[0045]On the basis of Example 1, the waste heat comprehensive recovery device also includes a drying bed girder waste heat recovery device;

[0046] The drying bed girder waste heat recovery device is a cooling water beam installed in the drying bed in the shaft furnace body, and the water outlet and inlet of the cooling water beam are respectively connected with the water inlet and water outlet of the steam-water separation device 12 through pipes.

[0047] The water circulation mode of the waste heat recovery device of the drying bed beam is the natural circulation vaporization cooling mode.

Embodiment 3

[0049] On the basis of Embodiment 2, the waste heat comprehensive recovery device also includes a waste heat recovery device for the wind guide wall girder;

[0050] The waste heat recovery device of the beam of the wind guide wall is a cooling water beam arranged in the wind guide wall of the shaft furnace body, and the outlet and inlet of the cooling water beam are respectively connected to the water inlet and outlet of the steam-water separation device 12 through pipelines. Dry bed girders.

[0051] The water circulation mode of the waste heat recovery device of the wind guide wall beam is the natural circulation vaporization cooling mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com