Differential pressure sensor device and encapsulation method thereof

A differential pressure sensor and pressure-guiding hole technology, applied in measuring devices, instruments, measuring fluid pressure, etc., can solve problems such as poor pressure-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with reference to the accompanying drawings and embodiments, so that anyone skilled in the art can make and use the present invention. The embodiments in the following description are by way of example only and modifications will be apparent to those skilled in the art. The general principles defined in the following description will apply to other embodiments, alternatives, modifications, equivalent implementations and applications without departing from the spirit and scope of the invention.

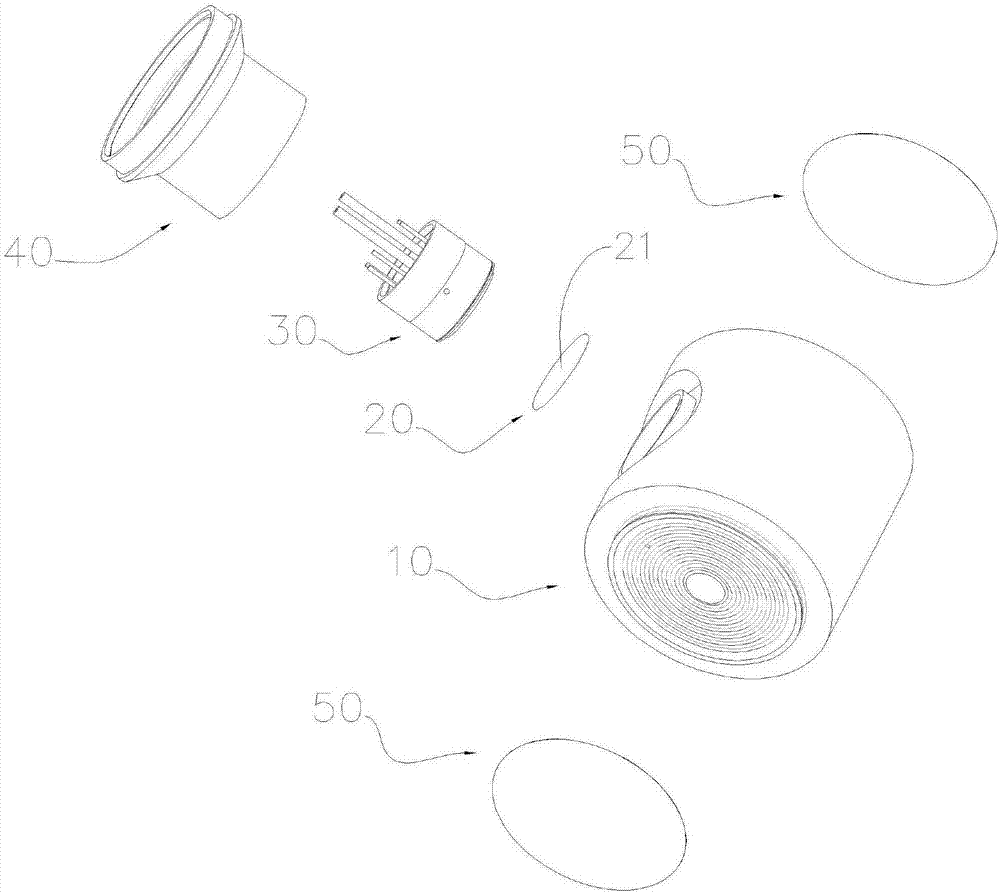

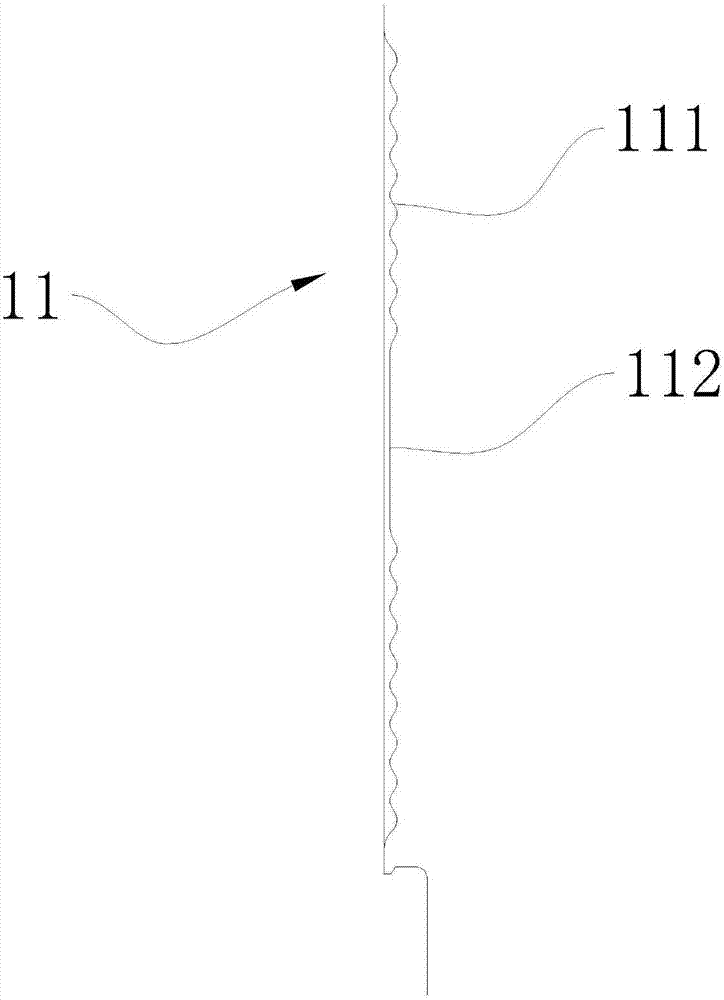

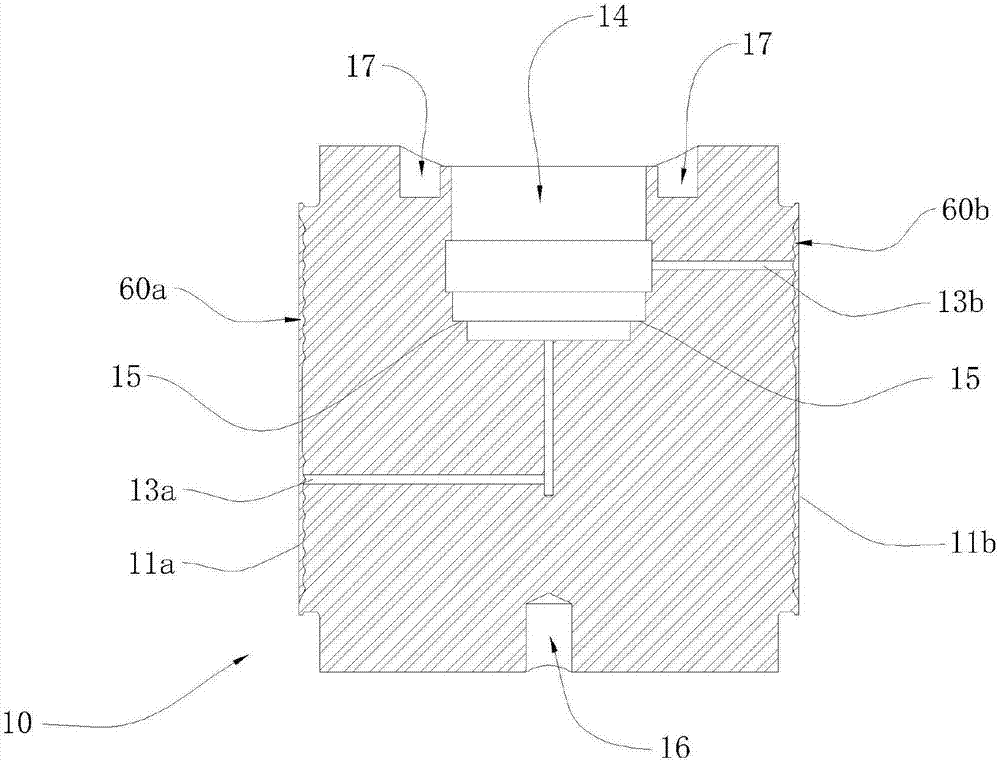

[0049] figure 1 It is a three-dimensional exploded schematic diagram of a connection method of a differential pressure sensor device according to a preferred embodiment of the present invention. Such as figure 1 As shown, a differential pressure sensor device includes a differential pressure sensor body 10, a spacer 20, a differential pressure sensor socket 30, a sleeve 40 and at least one pressure sensitive diaphragm 50, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com