Equipment and method for detecting air impermeability of wheel hub

A technology of air tightness detection and wheel hub, which is applied in the testing of fluid tightness, by detecting the appearance of fluid at the leakage point, and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of low work efficiency and high detection cost , expensive and other issues, to achieve the effect of improving work efficiency, high safety factor, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with accompanying drawing:

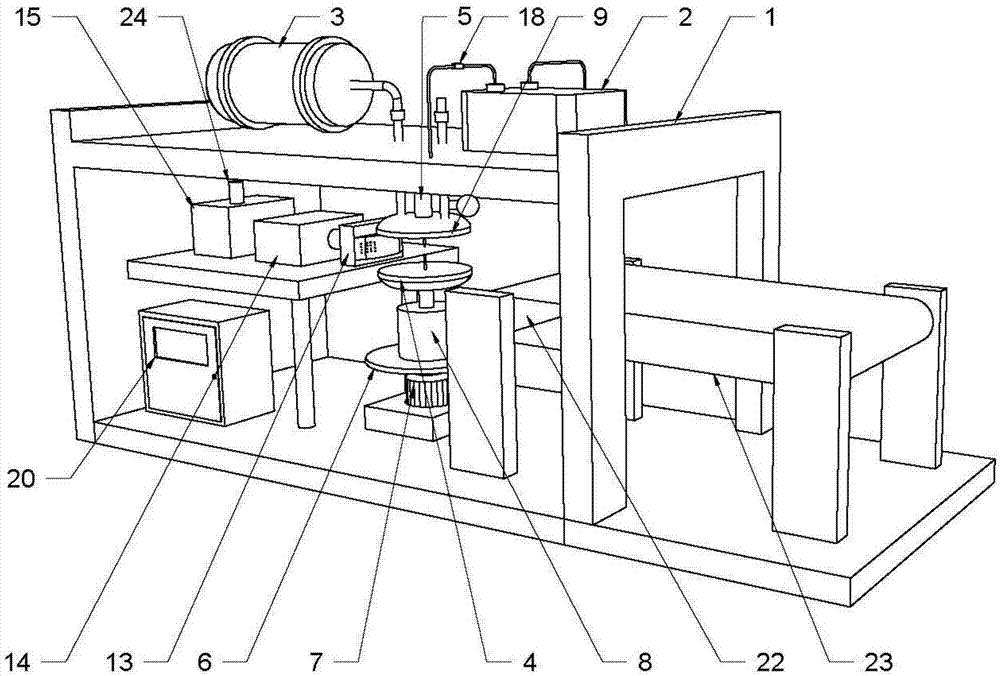

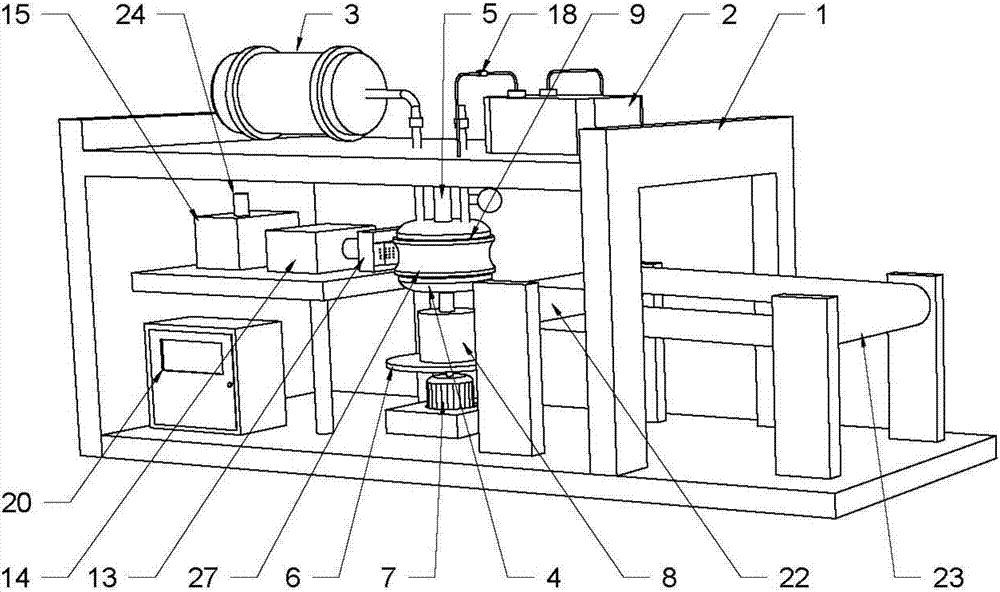

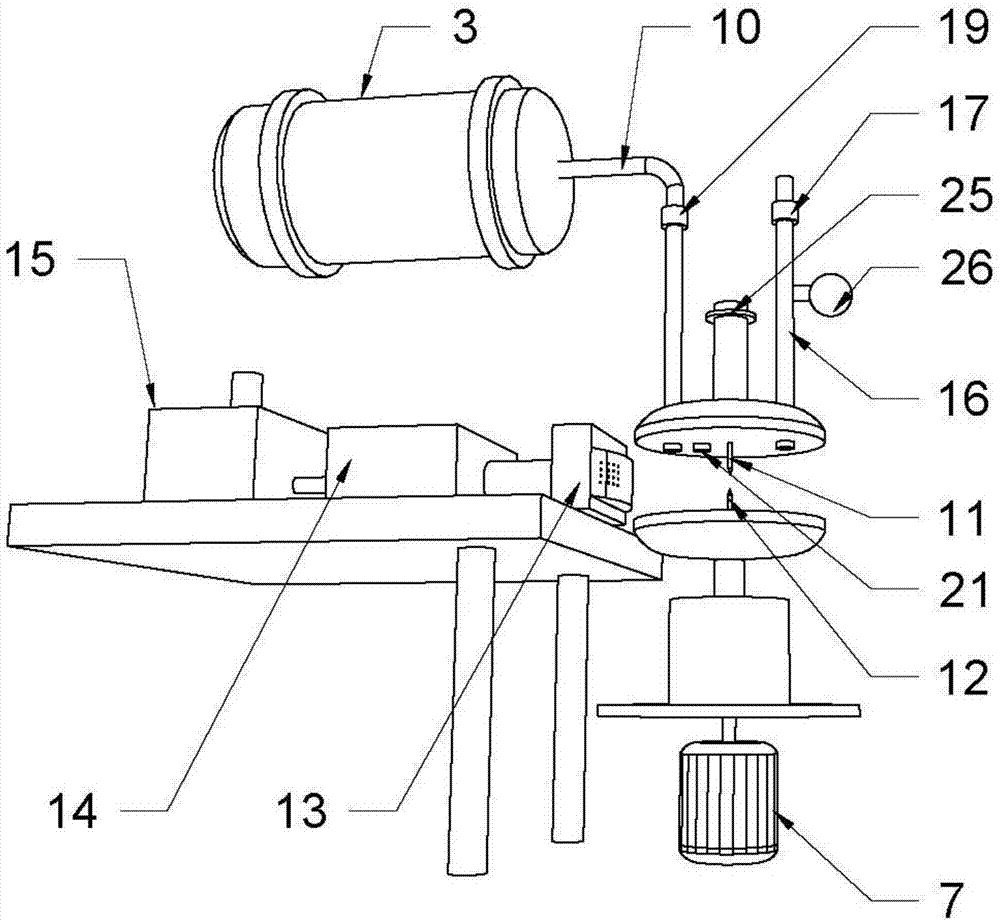

[0032] Such as Figure 1-3 Shown:

[0033]A device for detecting the airtightness of a wheel hub, comprising a frame 1, a power supply 2 is arranged on the frame 1, the voltage of the power supply 2 is 1500V, an air source 3, a conveying mechanism, a sealing and pressurizing mechanism, a charge detection mechanism, and a sealing and pressurizing mechanism It is arranged at one end of the conveying mechanism, and the charge detection mechanism is arranged at one side of the sealing and pressing mechanism; the sealing and pressing mechanism includes a first pressing block 4, on which a rotating shaft 5 is fixedly connected, and the rotating shaft 5 is rotatably connected to the frame 1, the frame 1 is also provided with a turntable 6 and a stepper motor 7, the turntable 6 is driven to rotate by the stepper motor 7, the turntable 6 is fixedly connected with a cylinder 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com