A 3D scanning point cloud data slice processing method for shoe sole contour

A technology of point cloud data and 3D scanning, applied in image data processing, details involving 3D image data, processing of 3D images, etc., can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below taking 42 yards of shoes sole as example, describe the embodiment of the present invention in detail in conjunction with accompanying drawing.

[0027] Step 1: Establish the coordinate system of the sole scan data

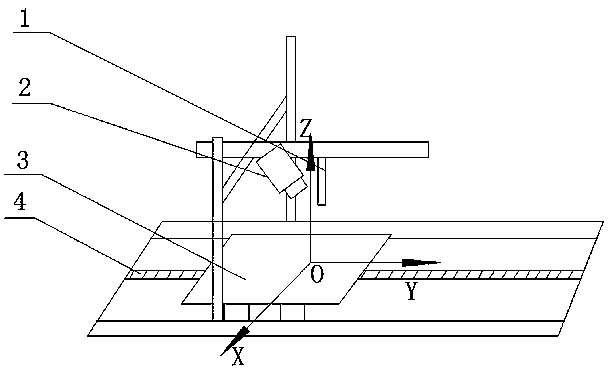

[0028] Such as figure 1 As shown, the coordinate system of the scanned data is established on the scanning table 3, with the center point O of the scanning table 3 as the origin, the length direction of the shoes, that is, the moving direction of the scanning table 3 along the screw rod 4 is the positive direction of the Y axis, Take the vertical upward as the positive direction of the Z axis, and the X direction is obtained by cross multiplying the Y direction and the Z direction.

[0029] Step 2: Get the 3D data of the sole

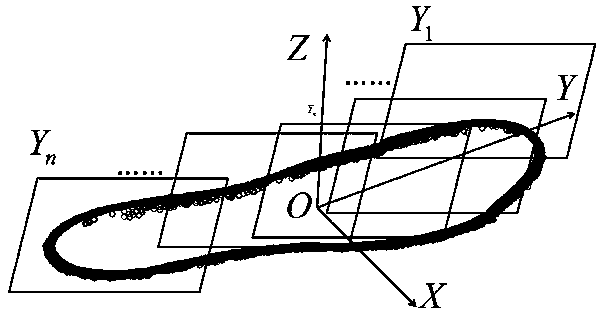

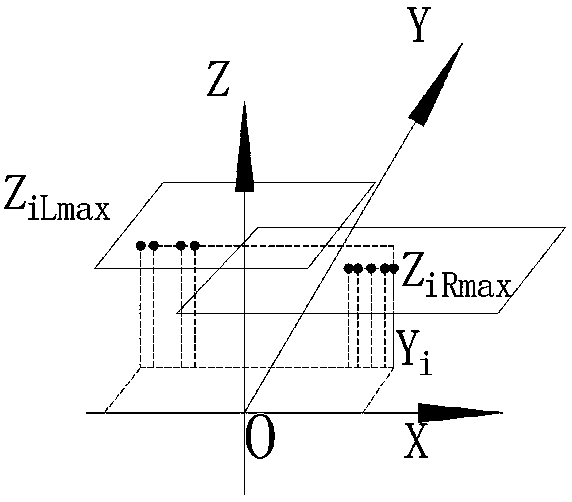

[0030] The sole is placed on the scanning table 3 along the Y direction in the length direction, and the sole is scanned along the positive direction of the Y axis. The laser 1 and the camera 2 scan the sole to obtain a three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com