Growth device for artificial crystal

A growth device and artificial crystal technology, which are applied in the directions of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of internal quality degradation of artificial crystal materials, affecting the performance of artificial crystal materials, and difficulty in ensuring temperature uniformity. To achieve good quality, reduce production costs, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

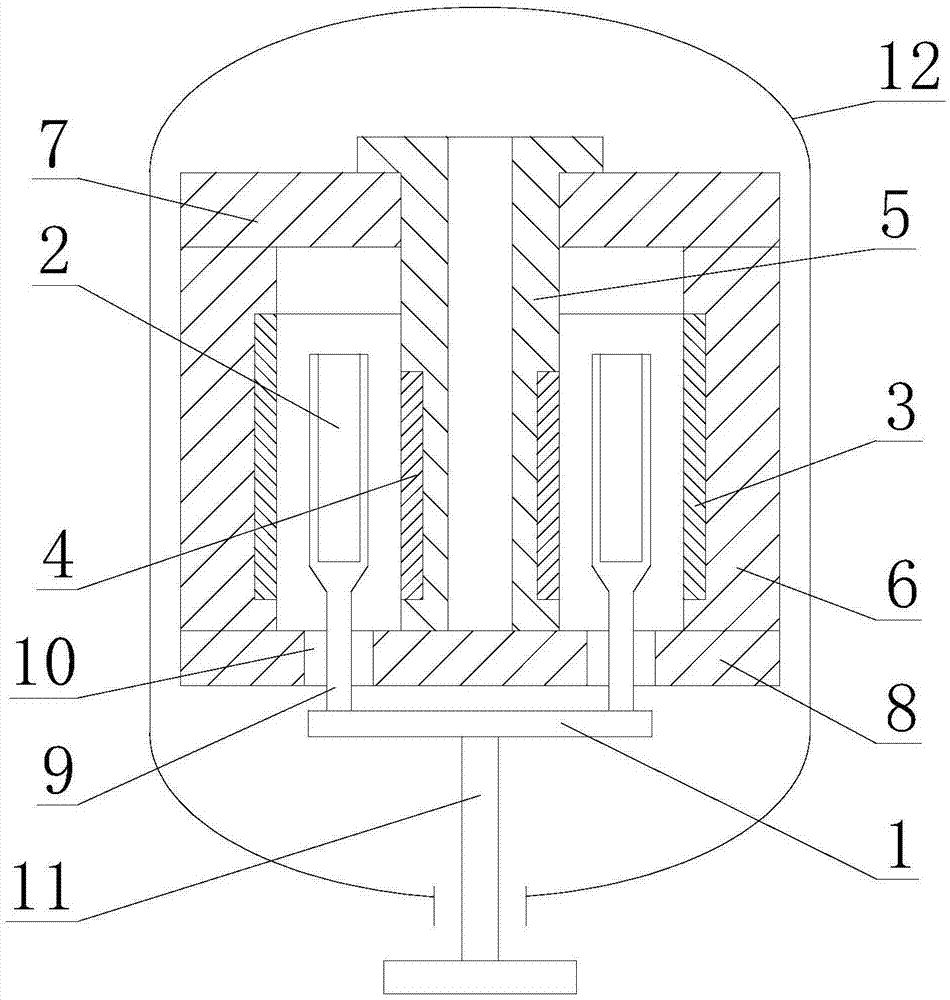

[0019] The technical scheme of the present invention will be further explained below in conjunction with the drawings.

[0020] See figure 1 As shown, the above-mentioned growth device for intraocular lens includes a tray 1, a plurality of crucibles arranged on the tray 1 and arranged on the tray 1 and arranged on the upper side of the tray 1 and arranged on the upper part of the tray 1 for containing A heat preservation mechanism for the hollow cavities of multiple crucibles 2. In this embodiment, the tray 1 is distributed in a horizontal direction, and a plurality of crucibles 2 are distributed in a vertical direction, and the surrounding center of the plurality of crucibles 2 is located on the axis of the tray 1. There are gaps between the bottom of the heat preservation mechanism and the tray 1.

[0021] The above-mentioned growth device for artificial crystals also includes an outer heater 3 located at the outer periphery of the plurality of crucibles 2 provided in the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com