Rail fastener system

A technology of rail fasteners and rails, which is applied in the direction of rails, roads, fixed rails, etc., can solve the problems of high cost, difficult system maintenance, and low system safety, and achieve improved bonding force, increased contact area and friction force, guarantee safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

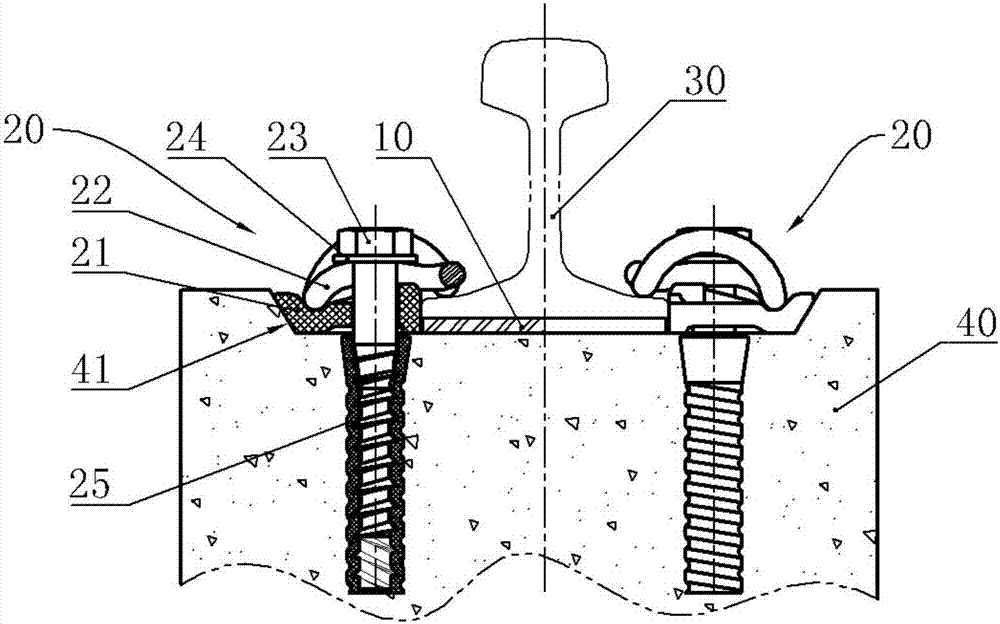

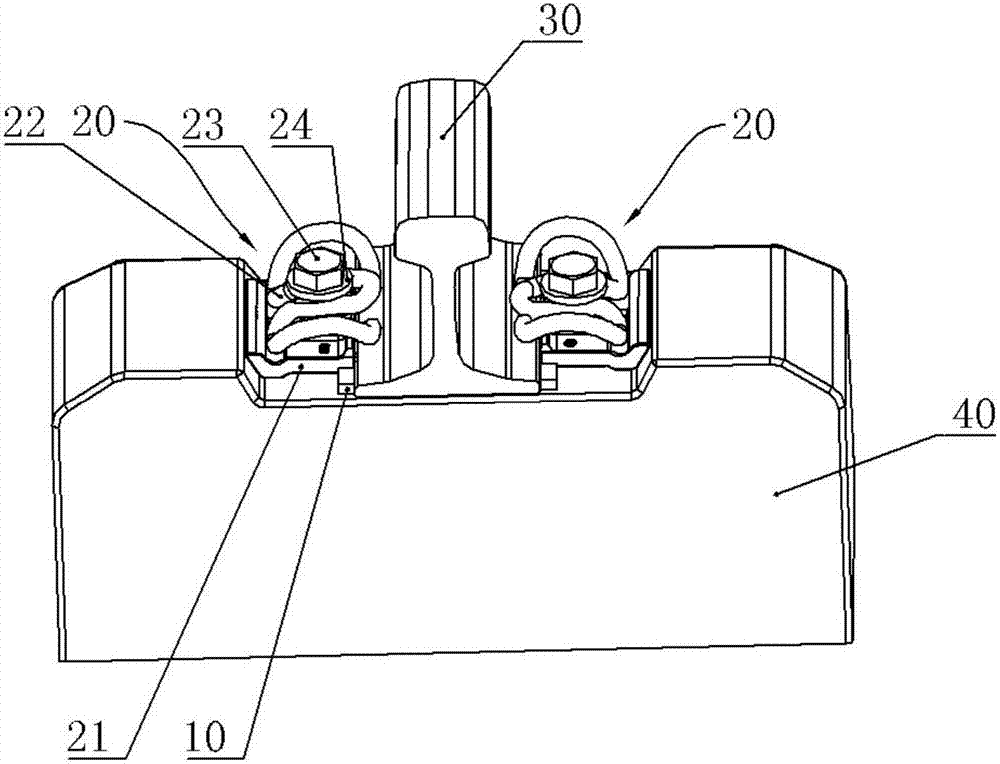

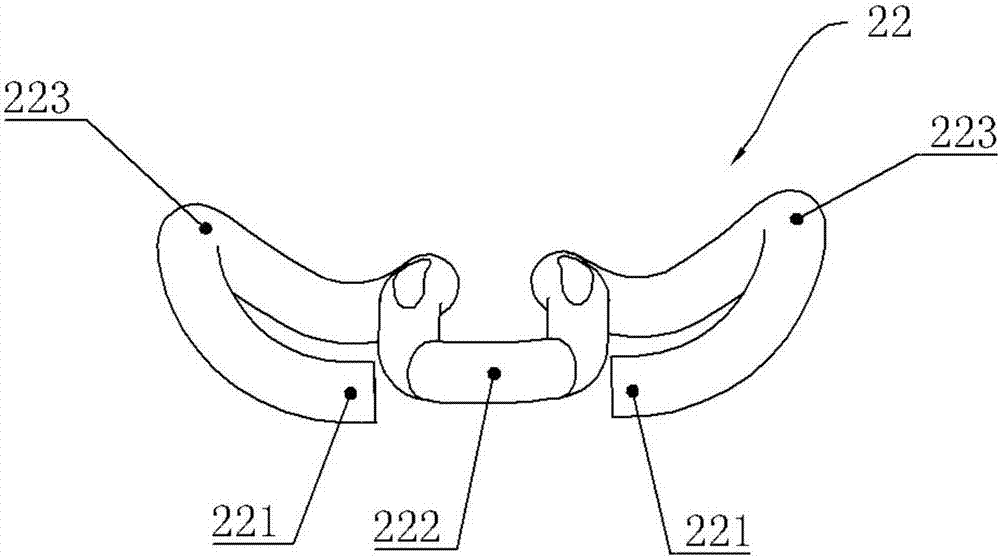

[0029] See figure 1 , figure 2 , image 3 and Figure 4 , the track fastener system of the present invention, which includes an under-rail backing plate 10 and two sets of fastening assemblies 20, the bottom of the rail 30 is placed on the sleeper 40 through the under-rail backing plate 10, and the two sets of fastening assemblies 20 are symmetrically arranged on the rail 30 On both lateral sides, the fastening assembly 20 includes a gauge baffle 21 , a W-shaped elastic bar 22 , a spiral spike 23 and a sleeve 25 , the sleeve 25 is pre-embedded in the sleeper 40 , and the gauge baffle 21 is placed in the sleeper 40 The upper side and the lateral side are against the rail 30 and the other side is against the shoulder 41 of the sleeper. The tail part 223 and the middle part 222 of the W-shaped elastic bar 22 are pressed on the rail gauge baffle 21, while the middle part 222 and the head 221 Pressed on the rail 30, the spiral spike 23 passes through the flat washer 24, the W-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com