Quick connector of magnetic type electrical test wire

A test line, magnetic suction technology, applied to the parts of electrical measuring instruments, measuring electrical variables, measuring device magnets, etc., can solve problems such as false touch, falling off, cumbersome connection operations, etc., to achieve convenient use and small contact resistance , The effect of speeding up the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

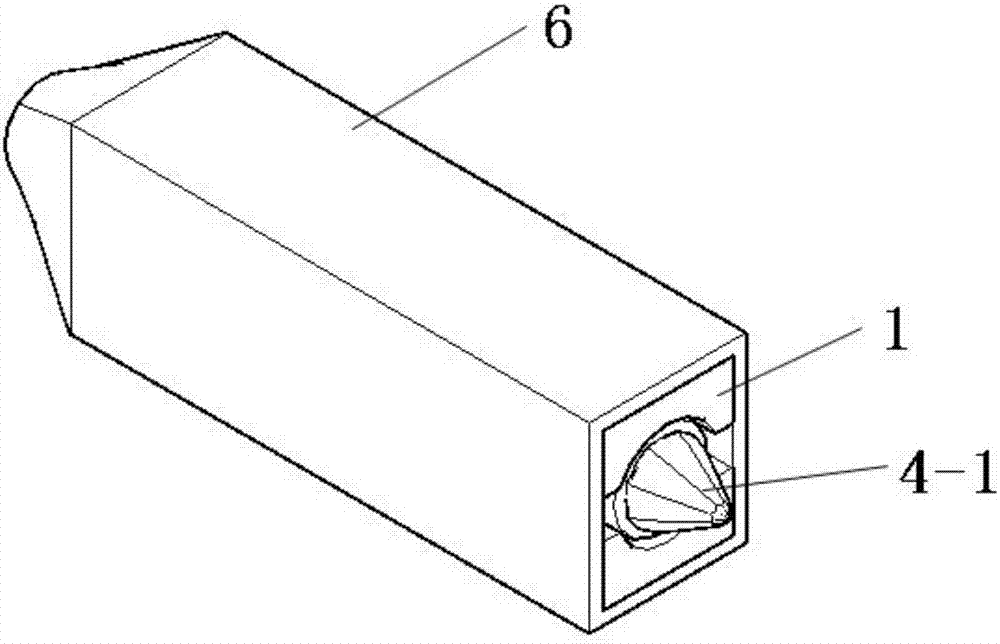

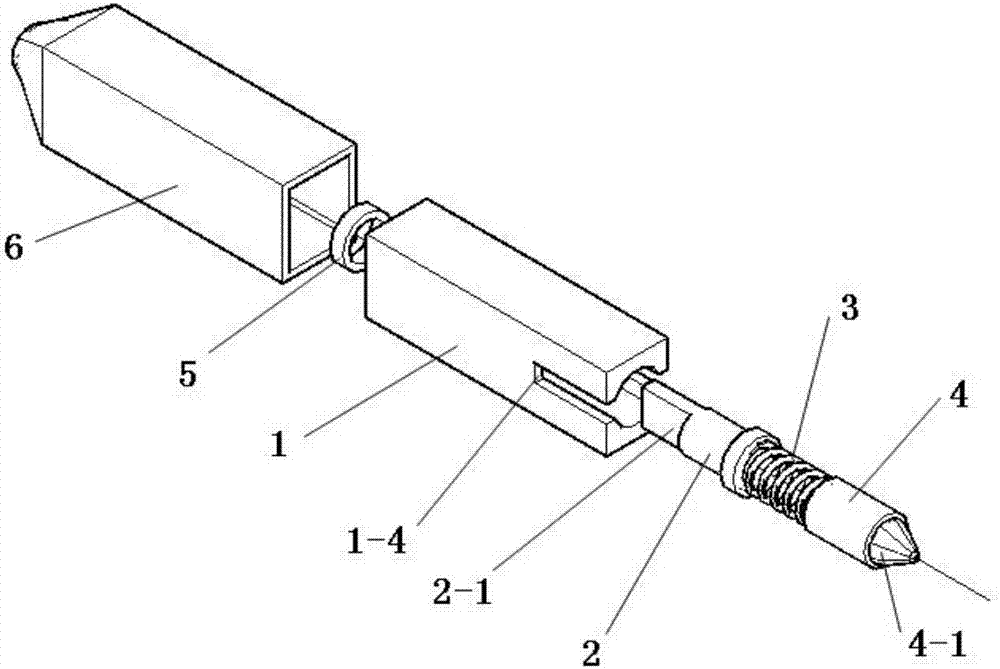

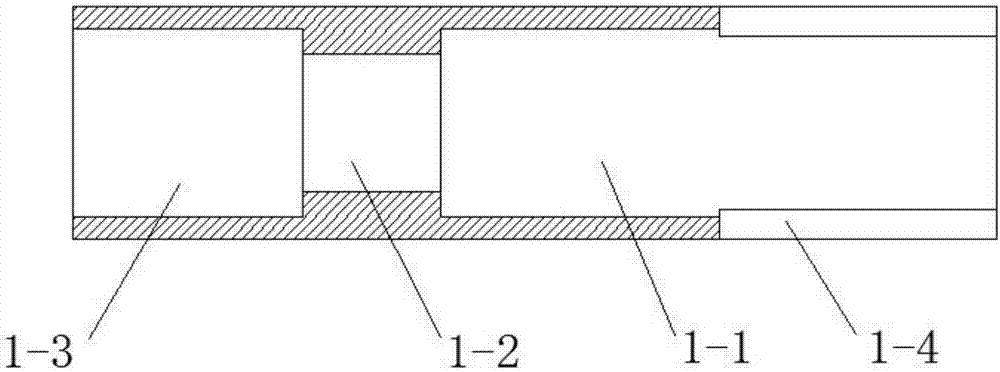

[0015] Specific embodiment 1: The quick connector of the magnetic suction type electrical test line in this embodiment includes an insulating sheath 6, an adsorption magnetic steel 1, a connecting bolt 2, a compression spring 3, a copper contact post 4 and a nut 5, and an adsorption magnetic steel 1 It is a rectangular block, and along the axial center line of the rectangular block, there are through holes consisting of contact hole 1-1, middle hole 1-2 and bolt hole 1-3. The contact hole 1-1 and the middle The hole 1-2 forms a stepped hole structure, one end of the compression spring 3 is set on the cap surface of the connecting bolt 2, the other end of the compression spring 3 is connected with the copper contact column 4, and the connecting bolt 2 is inserted into the middle hole 1-2 , the bolt rod of the connecting bolt 2 extends into the bolt hole 1-3, the nut 5 is tightly set on the bolt rod of the connecting bolt 2, the copper contact post 4 is located in the contact hol...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that one end of the compression spring 3 is welded on the cap surface of the connecting bolt 2 , and the other end of the compression spring 3 is welded to the copper contact post 4 .

[0019] In this embodiment, the copper contact post, the compression spring, and the wire connection bolt are tightly welded into one body, so as to increase the electrical conductivity and reduce the measurement error caused by the wire.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that there are opposite rectangular grooves 1-4 on the magnetic steel wall of the contact hole 1-1 section in the adsorption magnetic steel 1 .

[0021] The rectangular groove in this embodiment is along the axial direction of the cuboid body and communicates with the end face of the magnetic steel to facilitate the insertion and adsorption of some relay chip pins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com