12/10 permanent magnet auxiliary excitation switched reluctance motor

A switched reluctance motor and auxiliary excitation technology, which is applied in the direction of magnetic circuits, electric components, electrical components, etc., can solve the problems of reducing magnetic flux closing reluctance, small torque, torque ripple and large noise, etc., to achieve increased Electromagnetic torque, effect of increasing saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

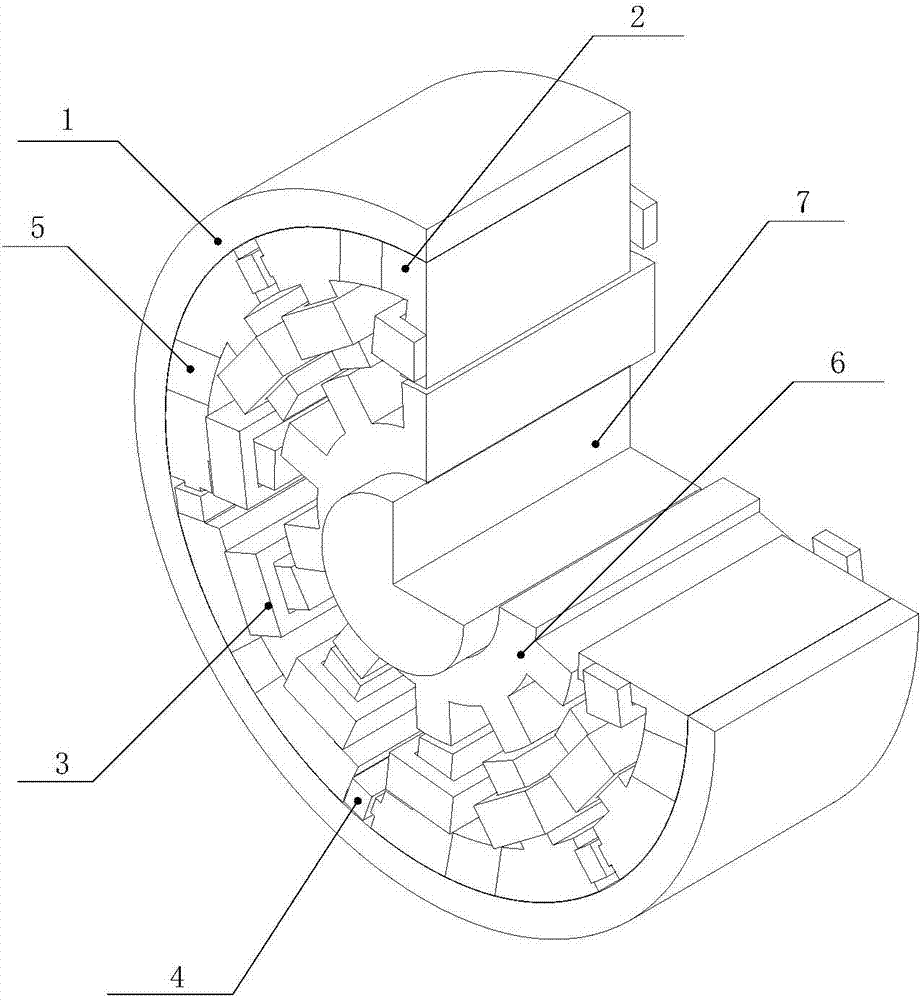

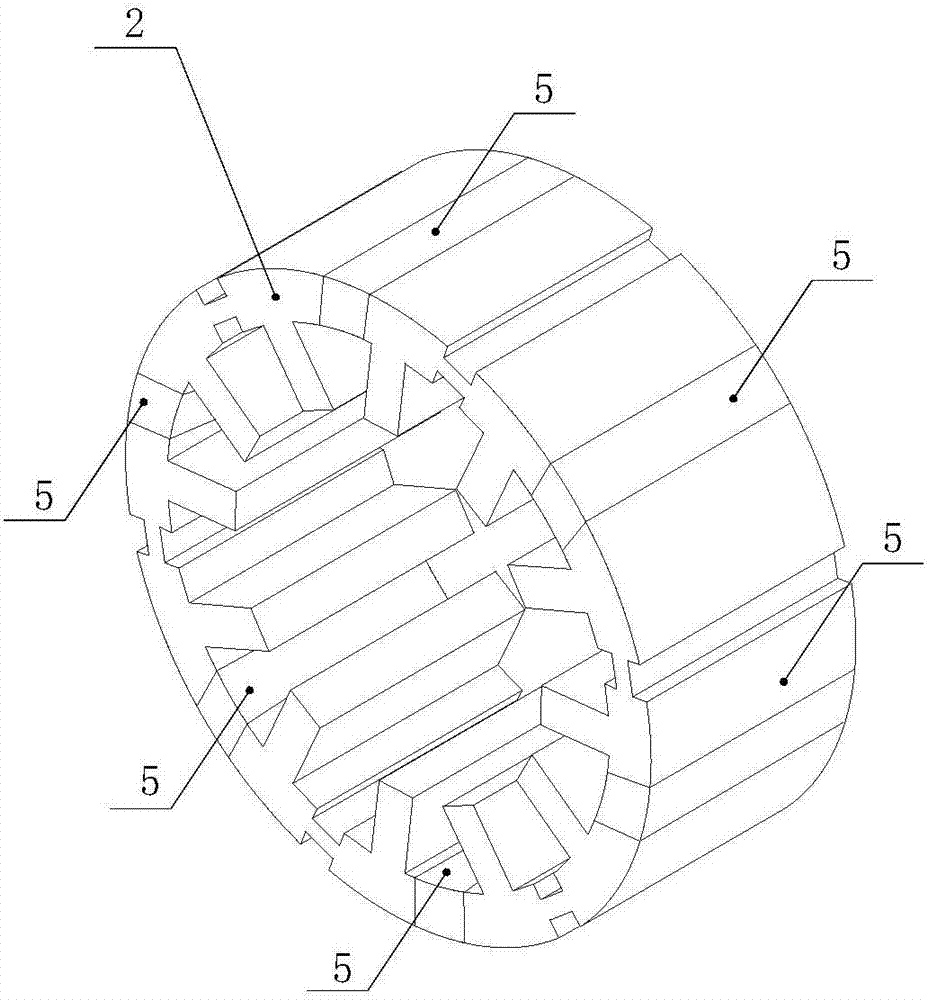

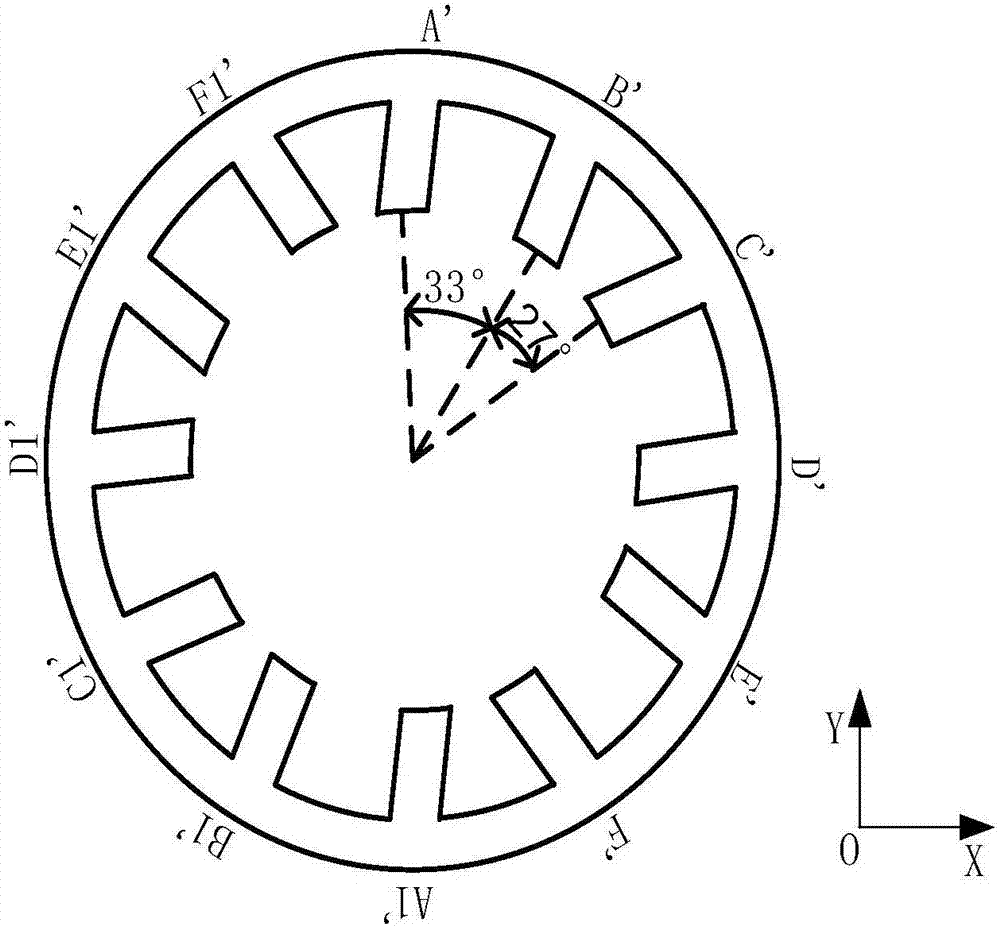

[0014] Such as figure 1 As shown, a 12 / 10 permanent magnet auxiliary excitation switched reluctance motor consists of a stator back yoke (1), a stator core (2), a torque winding coil (3), an auxiliary excitation coil (4), and a permanent magnet (5) , The rotor core (6) and the shaft (7) are composed. The inner side of the stator back yoke (1) is a stator core (2) and a permanent magnet (5), and the stator back yoke (1) is connected with the stator core (2) and the permanent magnet (5). The stator core (2) has 12 magnetic pole teeth, on which a torque winding coil (3) is wound, and the torque winding coil (3) provides a working magnetic field for the motor. The outer side of the stator core (2) is a stator back yoke (1), and the stator back yoke (1) is connected with the stator core (2). Define the outer diameter of the stator core (2) as r1, the inner diameter as r2, the stator tooth height as h1, and the stator tooth root arc length as λ. Among them, the inner diameter arcs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com