A kind of nickel-titanium alloy gradient flexible root canal file and its manufacturing method

A technology of nickel-titanium alloy and manufacturing method, which is applied in the direction of adding protective layer, dental prosthesis, surgery, etc., can solve the problem of root canal file failure, low cutting efficiency of the C2 section of the root canal, and deviation of the root canal axis from the original axis, etc. problem, to achieve the effect of good compliance, improved use safety, and efficient shaping

Active Publication Date: 2019-10-01

SHENZHEN SUPERLINE TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

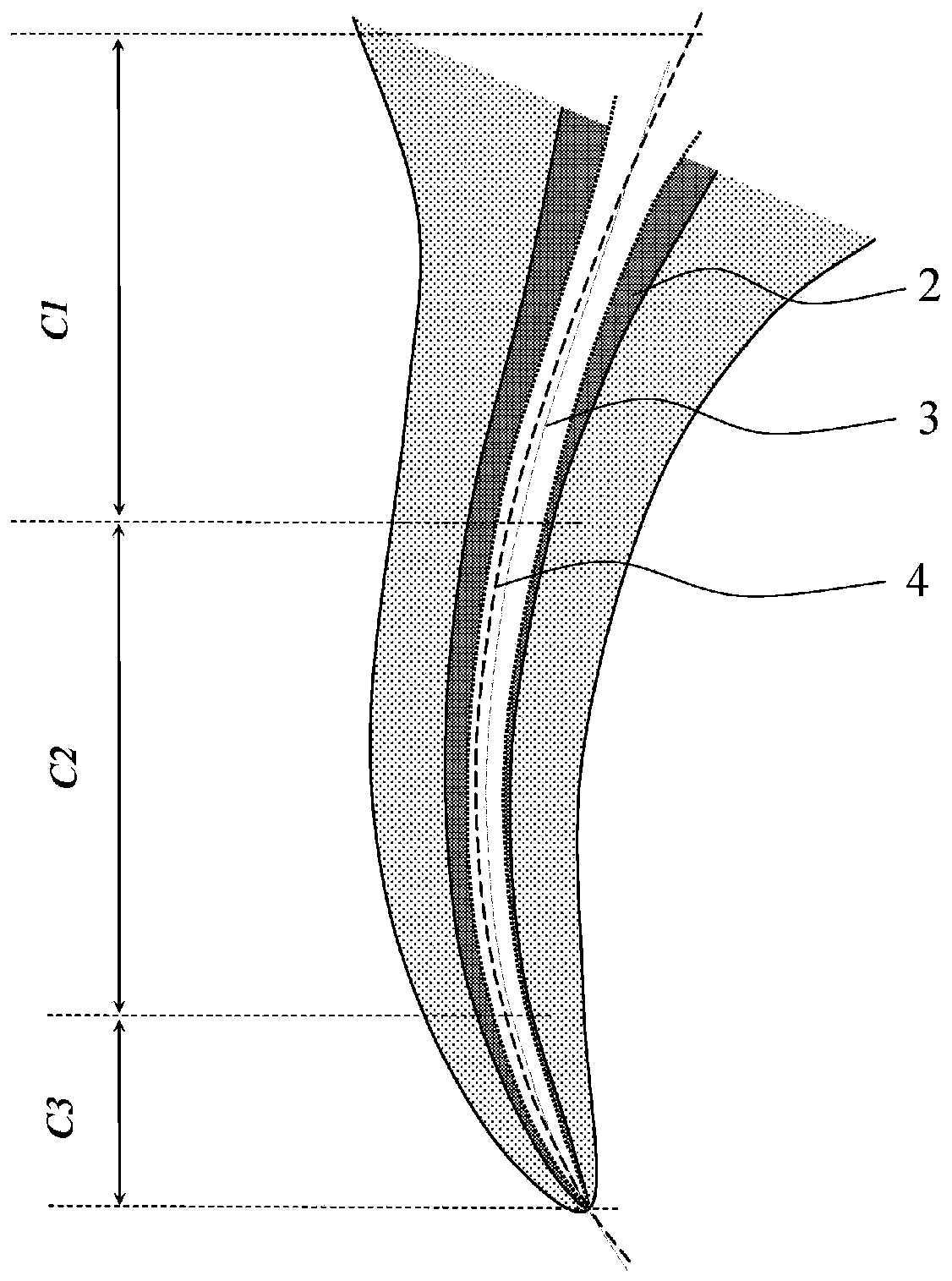

If the martensite M-phase segment is too long, although the fatigue life of the front segment of the root canal file is improved and the risk of root canal side penetration is reduced, the cutting efficiency of the C2 segment of the root canal is very low, and there is also martensite The axial distortion of the M-phase segment leads to the risk of root canal file failure; if the martensitic M-segment is too short, although it can meet the high-efficiency cutting of root canal C1 and C2 segments, it will also be like a superelastic root canal file, which is easy The root canal axis after shaping is seriously deviated from the original axis, especially in the C2 segment of the root canal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a nitinol gradient flexible root canal file, which comprises a root canal file tip part, a root canal file middle part and a root canal file root part divided along the axis of the nickel-titanium alloy gradient flexible root canal, the root canal file The inner structure of the tip of the root canal file is the martensite M phase, the middle part of the root canal file is the R phase, and the root of the root canal file is the austenite A phase. The invention also provides a manufacturing method of a nickel-titanium alloy gradient flexible root canal file. The beneficial effects of the invention are: effectively improving the use safety.

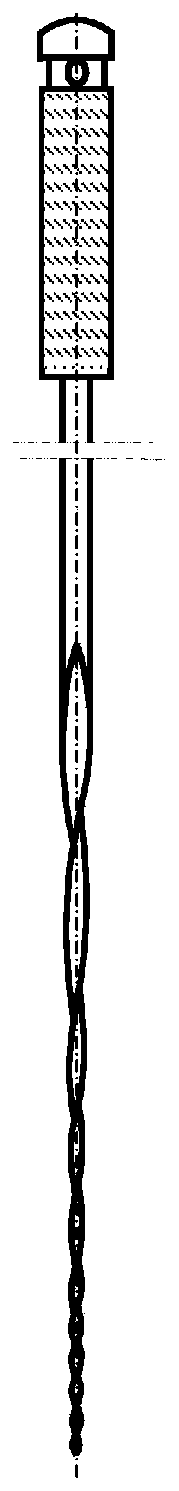

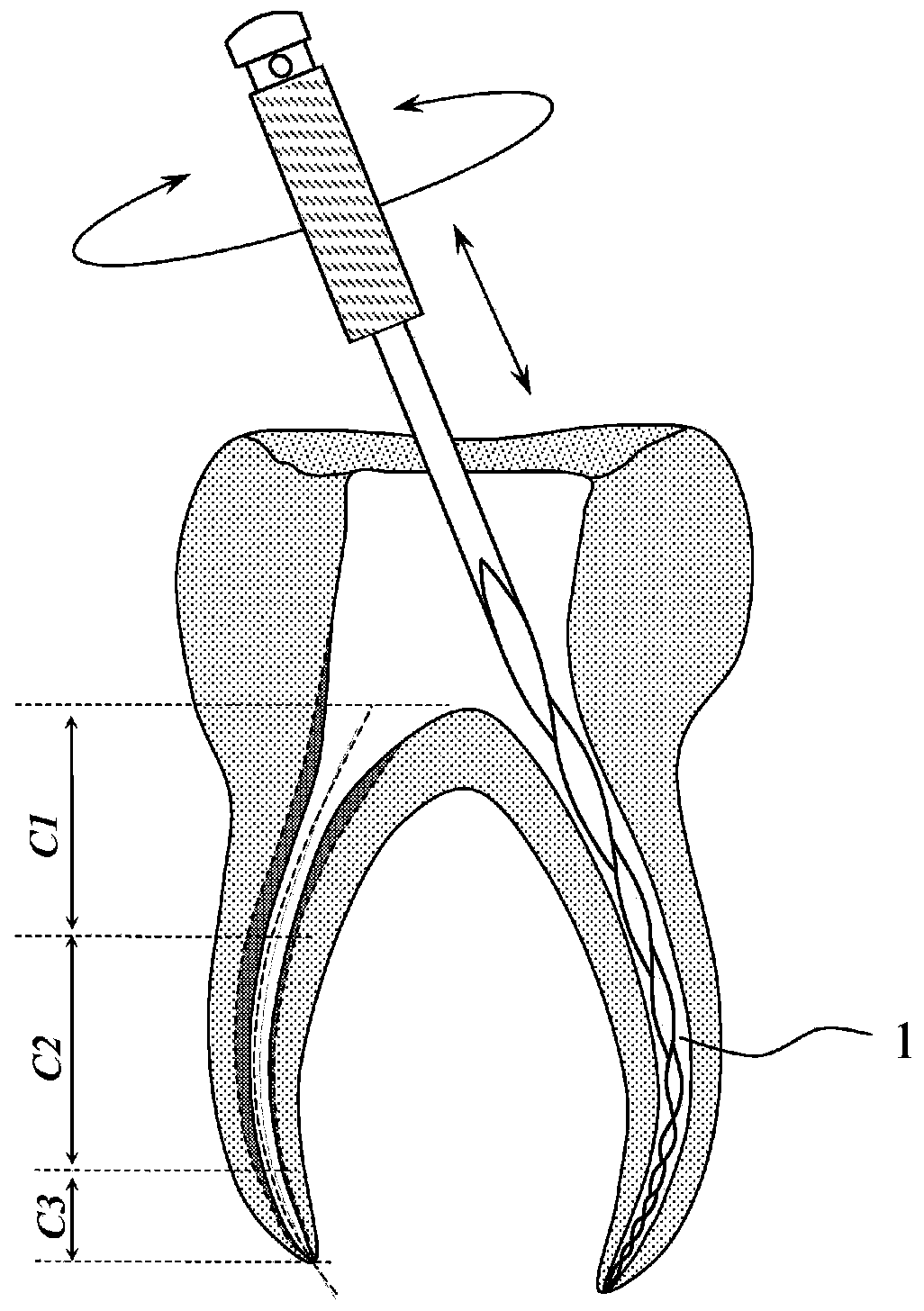

Description

technical field The invention relates to a dental instrument, in particular to a nickel-titanium alloy gradient flexible root canal file in the dental instrument and a manufacturing method thereof. Background technique As the main dental instrument, the root canal file is used to thoroughly clean the inside of the diseased root canal and the wall of the root canal, remove the diseased tissue, and create a complete and smooth root canal cavity. The working part of the root canal file has a certain cross-sectional shape, the outer contour has a certain taper, and there are helical cutting edges distributed on it, as shown in Figure 1. When the root canal file is working, it rotates at a certain speed in the root canal 1 to cut the inner surface of the root canal, so as to clean and shape the root canal, as shown in Figure 2. The root canal generally has a curved inverted cone-shaped structure. According to the structure, the root canal can be divided into three sections, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A61C5/42C22F1/10A61L31/02A61L31/14

CPCA61L31/022A61L31/14A61C5/42C22F1/10A61C2201/007A61C5/40A61C2201/00

Inventor 王中周劲送

Owner SHENZHEN SUPERLINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com