Filling machine aseptic system challenging experiment method

A filling machine, a challenging technology, applied in the challenging experimental field of the aseptic system of the filling machine, it can solve the problems of bad packages and long shelf life of the packaged products, and achieve the effect of ensuring safety and guaranteeing the aseptic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

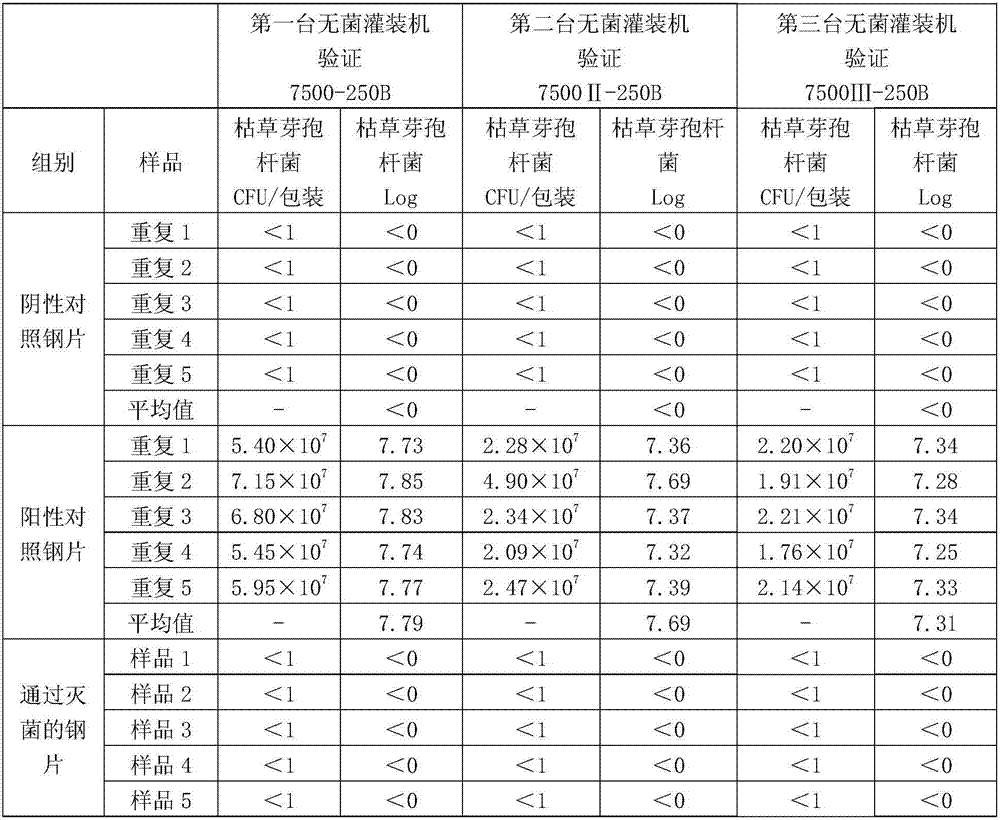

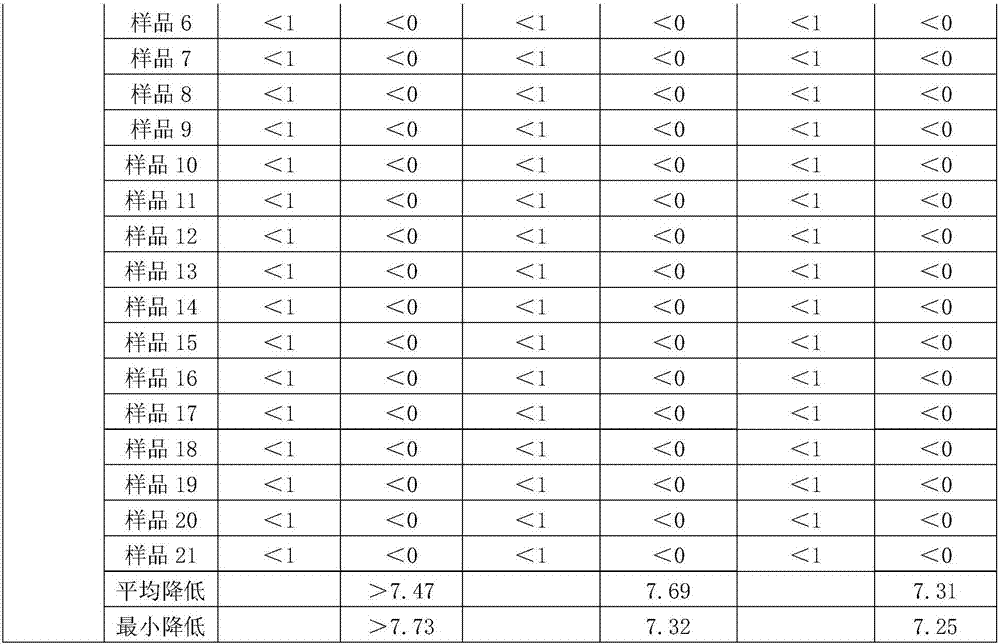

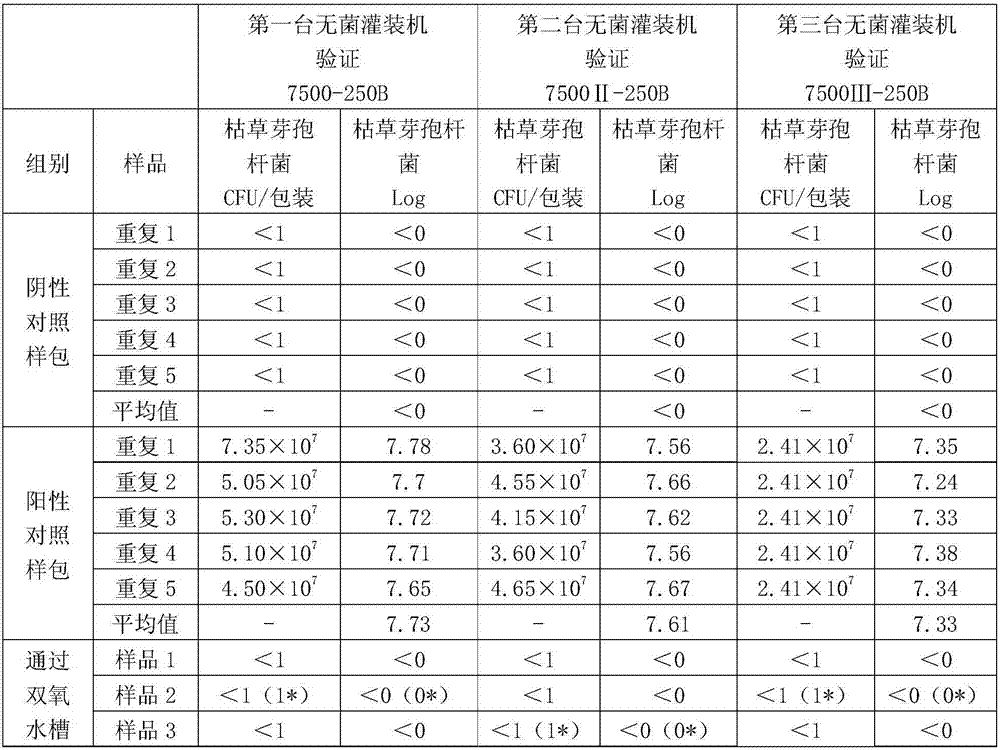

[0040] Example 1: The method of the challenging experiment of the aseptic system of the filling machine:

[0041] Shandong Bihai Machinery Technology Co., Ltd. entrusted Nuoan Like Commodity Inspection (Shanghai) Co., Ltd. to conduct challenging sterility verification for its BH7500 series filling machine aseptic system. The aseptic room of the BH7500 series filling machine uses high-temperature (270°C) air mixed with 35% hydrogen peroxide mist to sterilize the aseptic filling space (that is, the machine’s aseptic room, hereinafter referred to as the aseptic room). In addition, the BH7500 series aseptic filling machine uses hydrogen peroxide (about 35%) to act on the inner and outer surfaces of the packaging material for 7.4 seconds at 70-73 degrees Celsius to achieve sterilization of the packaging material. In order to verify the sterilization effect inside and outside the aseptic room and packaging materials of the BH7500 series aseptic filling machine, this project will eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com