Spiral rice circulation drying exhaust gas secondary utilization device

A cyclic drying and spiral technology, applied in the field of crops, can solve the problems of incomplete drying, easy softening of paddy and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

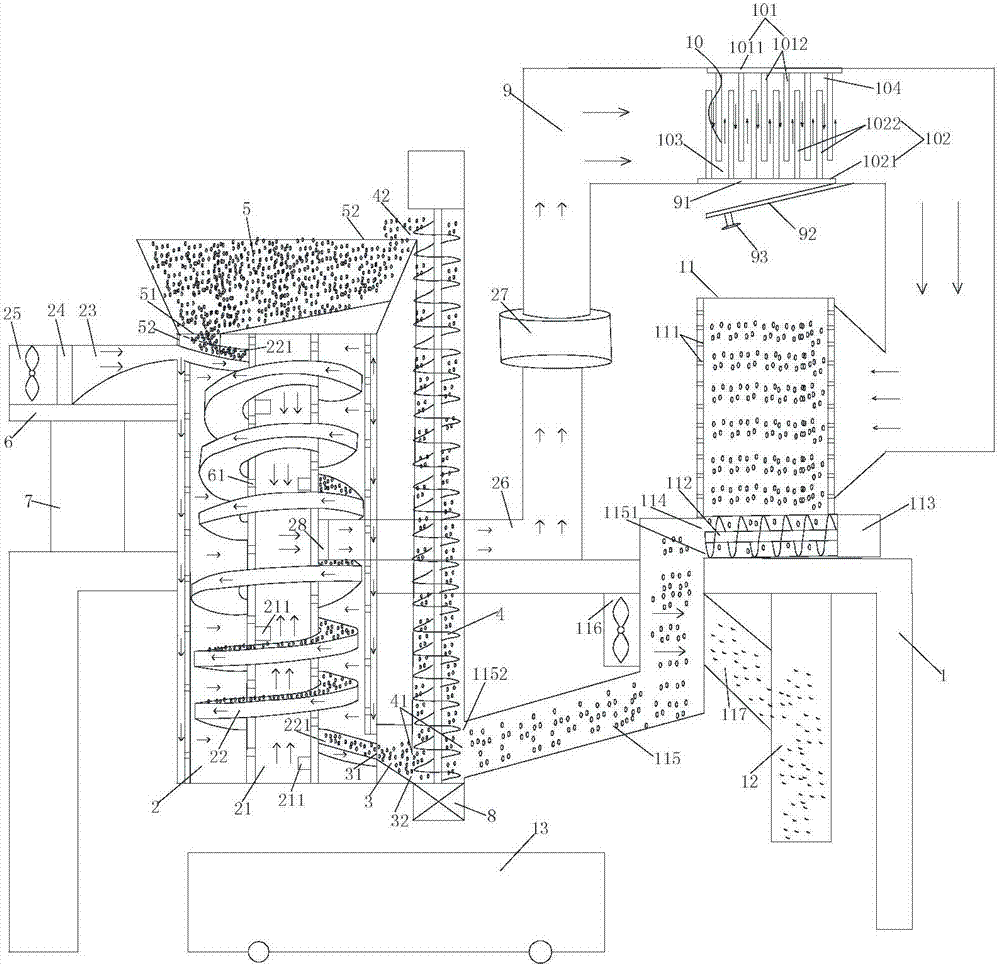

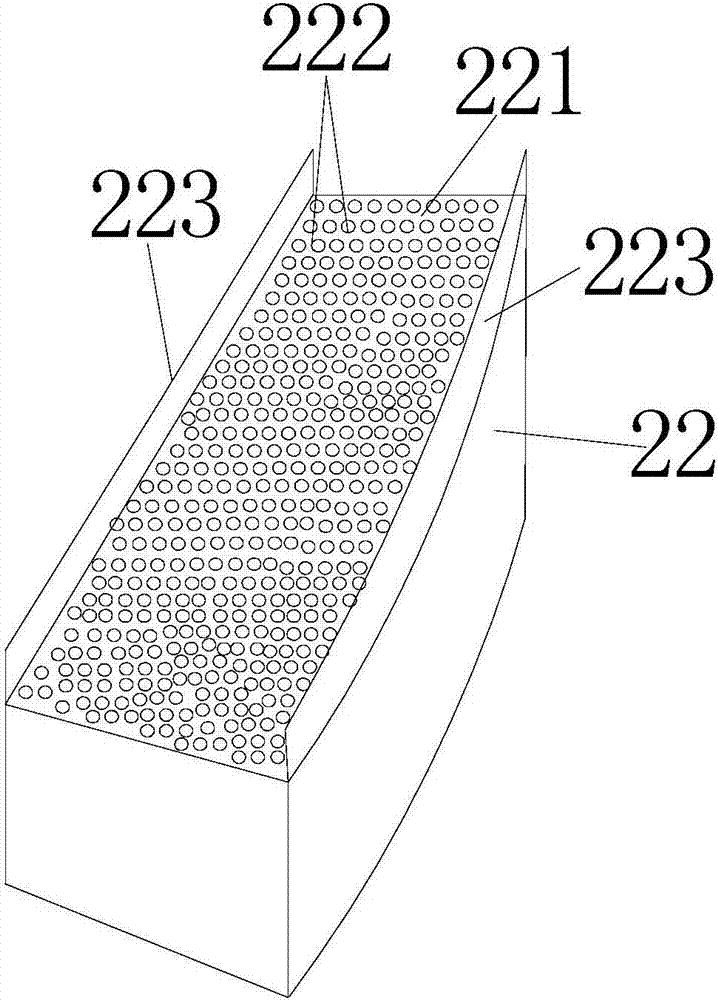

[0016] refer to figure 1 and figure 2 As shown, a spiral type rice circulation drying exhaust gas secondary utilization device of the present invention is characterized in that: it includes a bracket 1, and the bracket 1 is equipped with a drying buffer bin 2 whose tank wall is a hollow air outlet structure, a discharge The warehouse 3 and the auger conveyor 4, the dry buffer bin 2, the discharge bin 3 and the auger conveyor 4 are arranged side by side, and the auger conveyor 4 is vertically arranged; the dry buffer bin 2 is provided with an inlet Material bin 5, the center of the dry buffer bin 2 is provided with a hollow wind guide cylinder 21, the hollow wind guide cylinder 21 is perpendicular to the bottom of the dry buffer bin 2 and the bottom of the feed bin 5, the hollow Air suction holes 61 are provided on the side wall of the wind guide circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com