Spiral type grain circulating electrothermal wind drying device

A drying device and electric hot air technology, applied in the field of crops, can solve the problems of affecting efficiency, insufficient drying efficiency, poor heating effect, etc., and achieve the effect of improving drying efficiency and speeding up the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

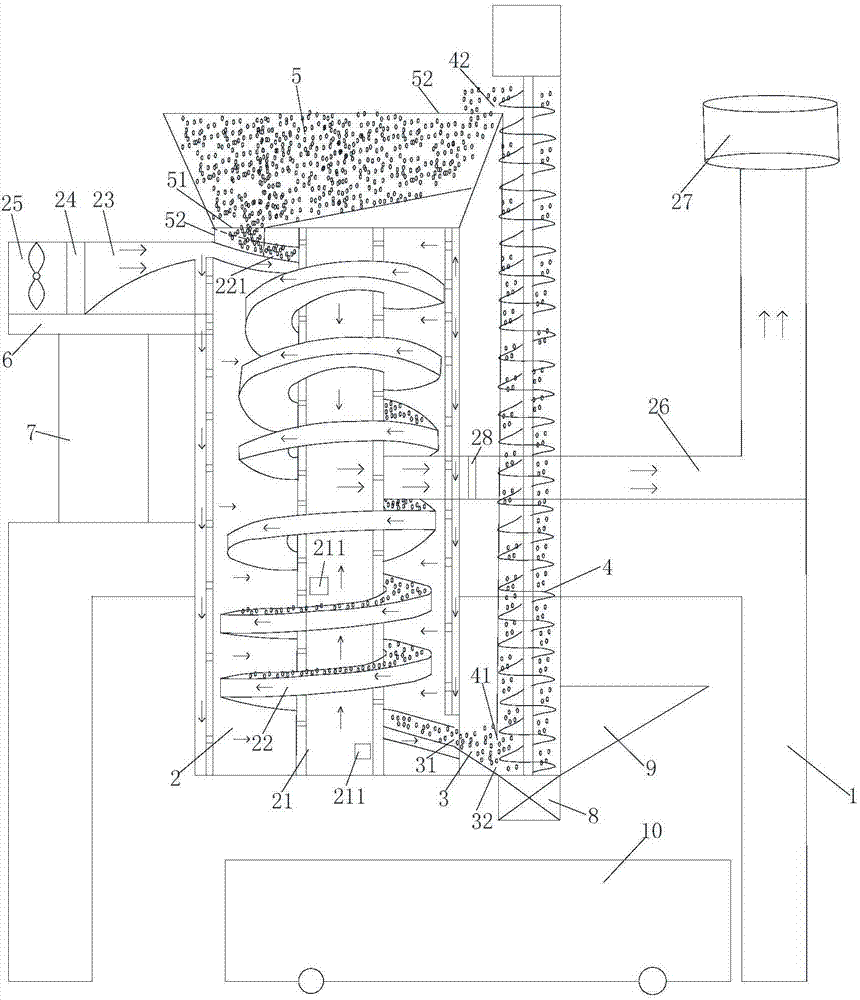

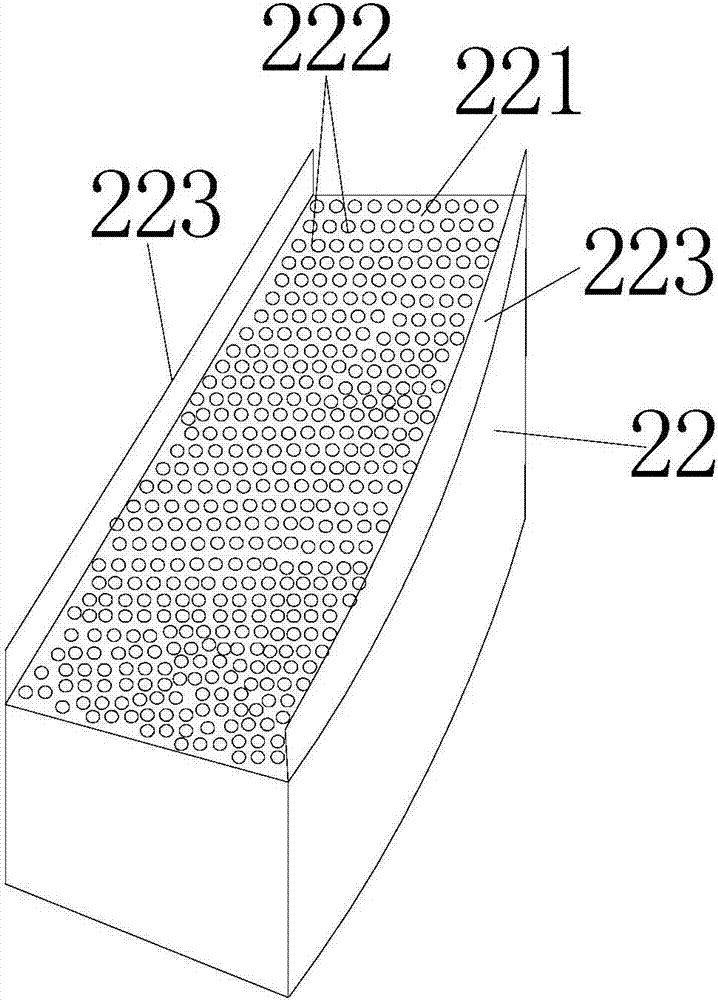

[0015] refer to figure 1 and figure 2 As shown, a spiral type grain circulating electric hot air drying device of the present invention is characterized in that: it includes a support 1, and the support 1 is provided with a drying buffer bin 2, a discharge bin 3 and an auger conveyor 4. The tank wall is a dry buffer bin 2 with a hollow air outlet structure, a discharge bin 3 and an auger conveyor 4 are arranged side by side, and the auger conveyor 4 is vertically arranged; the dry buffer bin 2 is provided with a feed bin 5. The center of the dry buffer bin 2 is provided with a hollow wind guide cylinder 21. The hollow wind guide cylinder 21 is perpendicular to the bottom of the dry buffer bin 2 and the bottom of the feed bin 5. The hollow wind guide The outer wall of the cylinder 21 is provided with a spiral conveying pipe 22, and the spiral conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com