Method and system for optimizing maintenance of mechanical system based on proportional hazard model

A mechanical system and failure rate technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as immature monitoring methods, and achieve the effect of accurate maintenance or replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

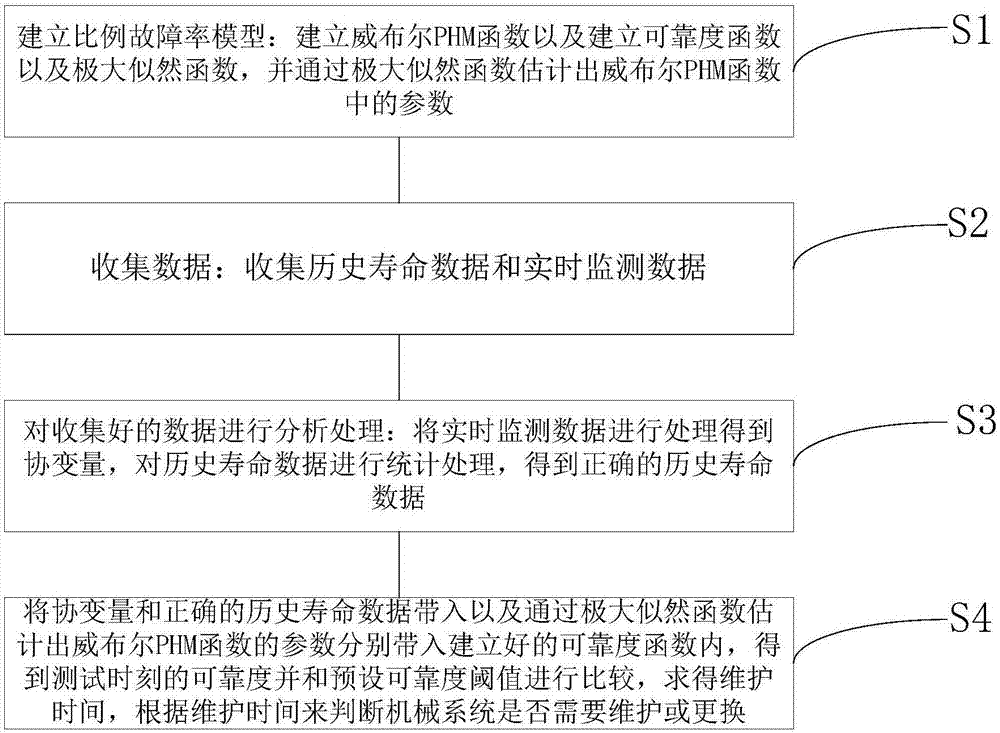

[0046] A maintenance method for optimizing a mechanical system based on a proportional failure rate model, comprising:

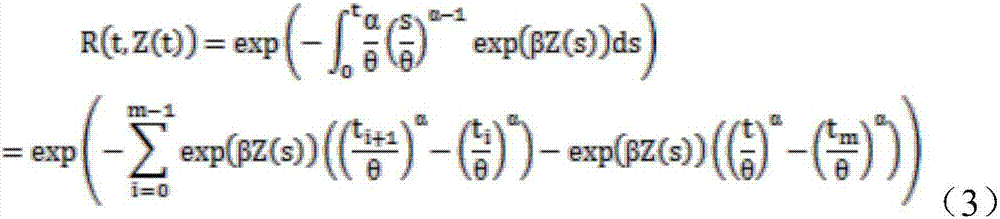

[0047] S1. Establish a proportional failure rate model: establish a Weibull PHM function, a reliability function and a maximum likelihood function, and estimate the parameters in the Weibull PHM function through the maximum likelihood function;

[0048] S2. Collect data: collect historical life data and real-time monitoring data;

[0049] S3. Analyze and process the collected data: process the real-time monitoring data to obtain covariates, perform statistical processing on historical life data, and obtain correct historical life data;

[0050] S4. Bring the covariates and the correct historical life data and the parameters of the Weibull PHM function estimated by the maximum likelihood function into the established reliability function to obtain the reliability of the test time and the preset reliability Compared with the threshold value, the maintenance t...

Embodiment 2

[0065] We will give an overview of the method described above with the optimization of the table change time of a mill-turn machining center. The accumulated data includes fault diagnosis data and monitoring data, and the monitoring data consists of vibration amplitudes in the horizontal, vertical and vertical directions of the workbench. Feature extraction is performed on the raw vibration data in each direction, including 12 time-domain features with mean x m , peak x p , the square root amplitude x ra , the square root mean x rms , variance x v , standard deviation x std , skewness x ske , kurtosis (x k ), the peak index x c , margin index x ma , waveform index x sha and pulse index x i . The first four parameter indicators reflect the vibration amplitude and energy in the time domain, and the remaining indicators represent the distribution of the signal time series in the time domain. In the frequency domain, the wavelet packet method is used to decompose the v...

Embodiment 3

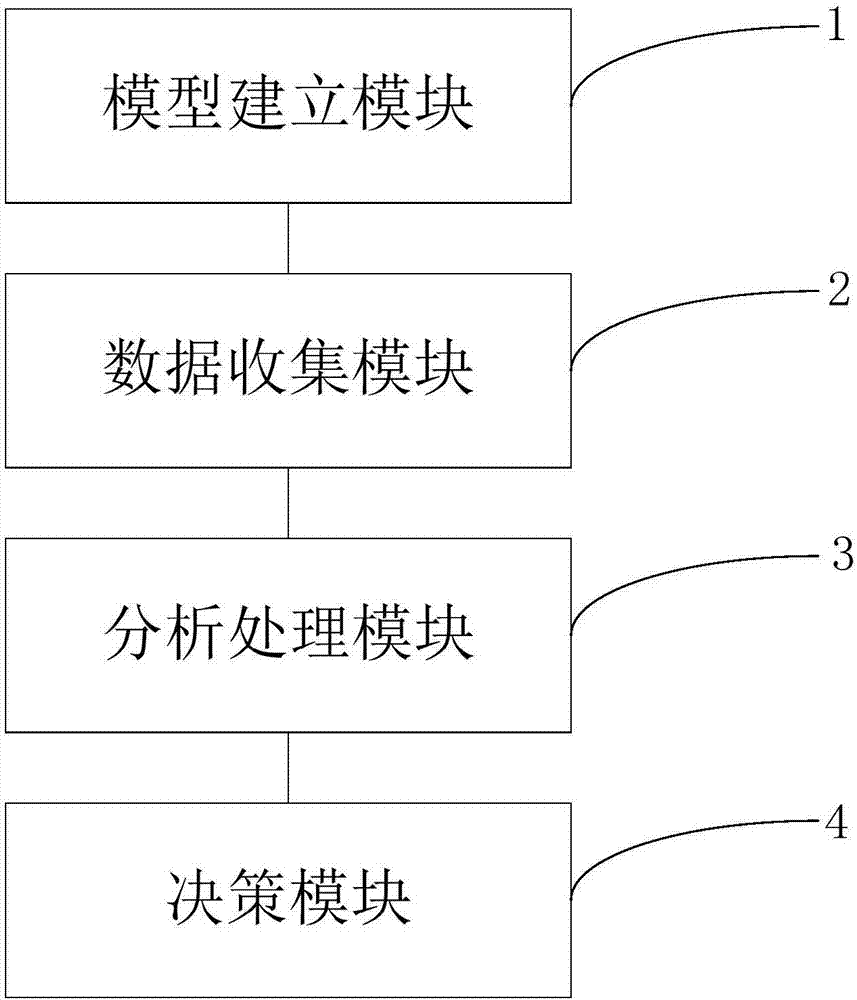

[0076] Embodiment 3 is a system embodiment of Embodiment 1, a maintenance system based on a proportional failure rate model to optimize a mechanical system, such as figure 2 shown, including:

[0077] A maintenance system for optimizing a mechanical system based on a proportional failure rate model, comprising:

[0078] Model building module 1: used to establish a proportional failure rate model: establish a Weibull PHM function, a reliability function and a maximum likelihood function, and estimate the parameters in the Weibull PHM function through the maximum likelihood function;

[0079] Data collection module 2: used to collect data: collect historical life data and real-time monitoring data;

[0080] Analysis and processing module 3: used to analyze and process the collected data: process real-time monitoring data to obtain covariates, perform statistical processing on historical life data, and obtain correct historical life data;

[0081] Decision-making module 4: It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com