Method for automatically generating decorative pattern expansion drawing of rotating symmetric porcelain

A rotationally symmetric and automatic generation technology, applied in 2D image generation, instruments, image analysis, etc., to save manpower and material resources, reduce the need to touch precious artifacts, and protect artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

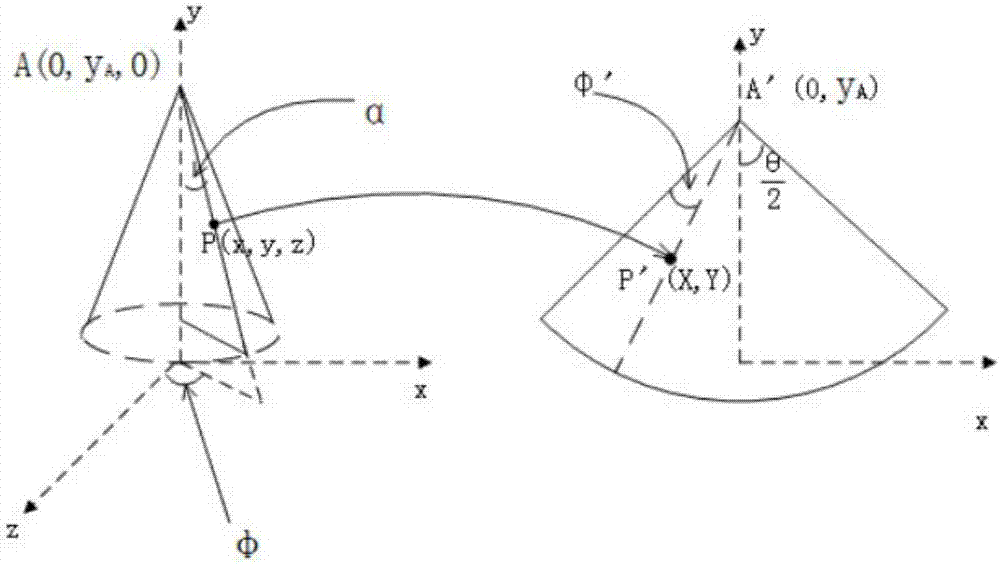

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings.

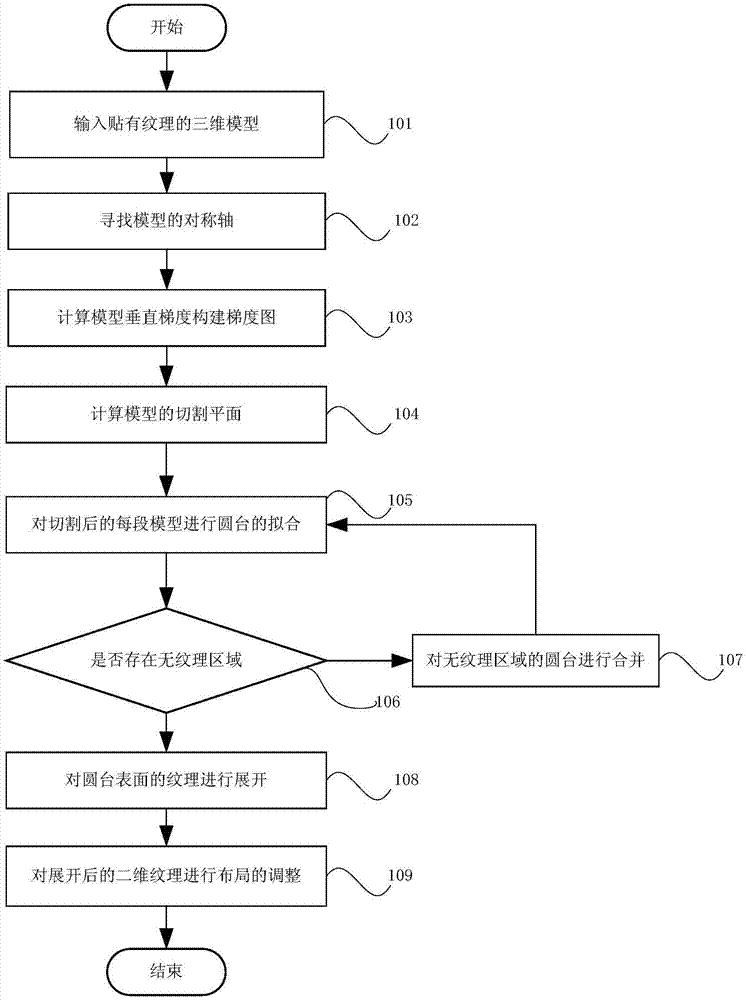

[0041] Such as figure 1 As shown, the present invention provides a method for automatically generating a pattern development diagram facing rotationally symmetrical porcelain, comprising the following steps:

[0042] Step one 101, input model data information with two-dimensional texture;

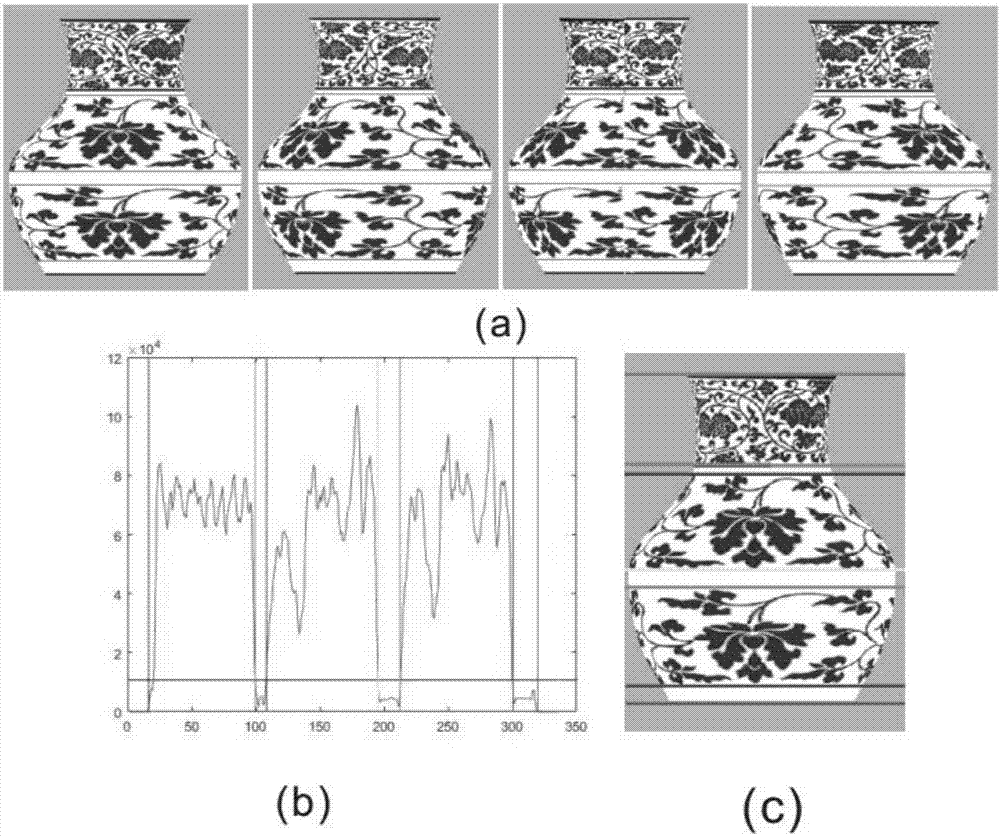

[0043] Step 2 102, based on the upright model of the symmetrical axis rotation model, and then obtain the front view in four directions; Step 3 103, use the gradient operator to analyze the obtained four front views, and generate the cumulative gradient of the model picture;

[0044] Among them, the analysis based on the gradient operator is specifically to use the Sobel gradient operator to calculate the vertical gradient of the front view in the four directions of the model, and accumulate the sum of the absolute values of the front view along the horizontal direction to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com