motor control unit

A technology of control device and motor, applied in the direction of motor control, AC motor control, control system, etc., can solve the problems of increased switching loss, higher harmonic component and higher harmonic loss, etc., to achieve a high-output cooling system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

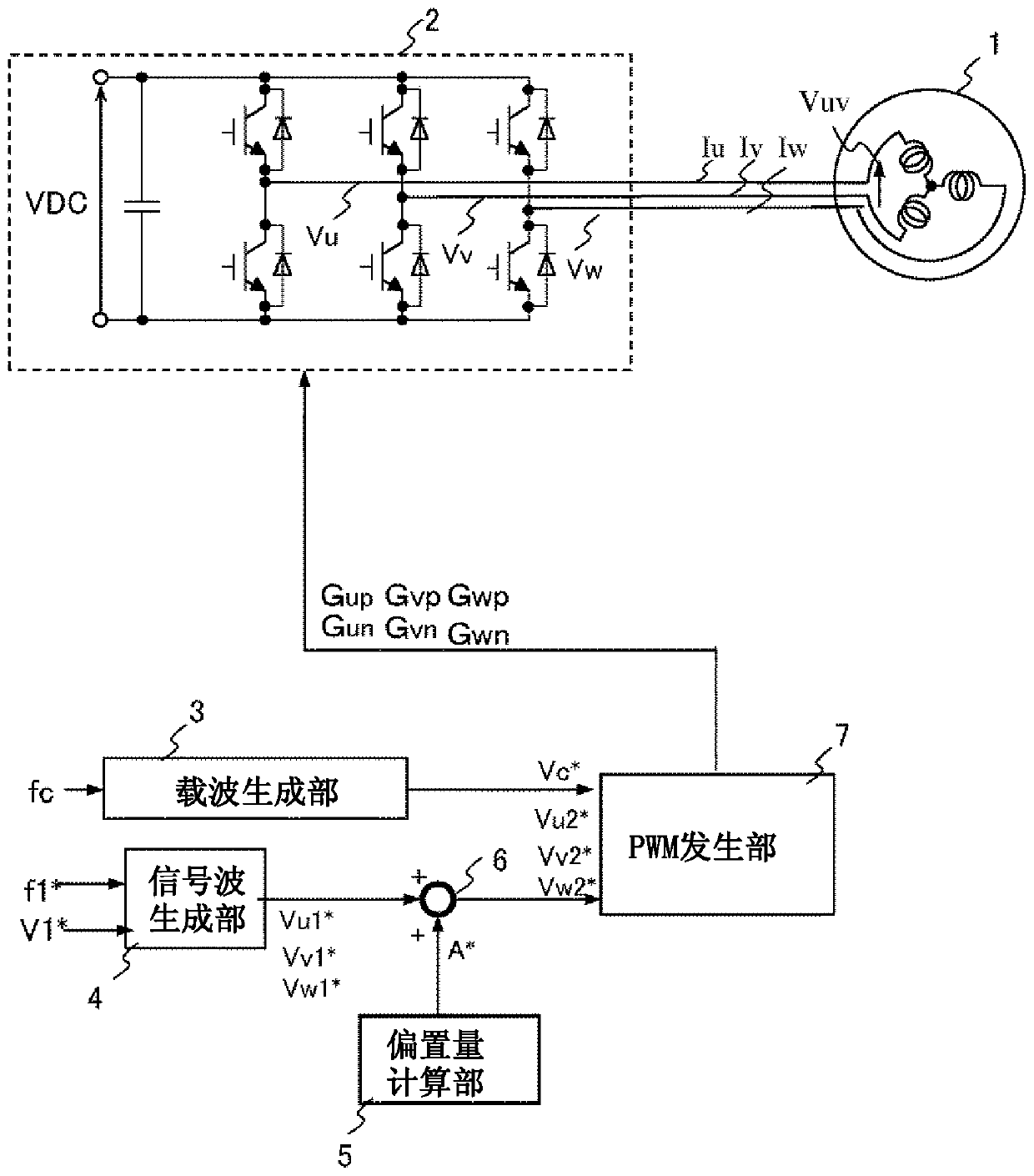

[0029] figure 1 is a configuration diagram of the motor control device in Embodiment 1, figure 2 is an element of the system. AC motor 1 is supplied with pulse voltages (U-phase pulse voltage Vu, V-phase pulse voltage Vv, W-phase pulse voltage Vw) from inverter 2, thereby flowing three-phase AC currents (U-phase current Iu, V-phase current Iv, The W-phase current Iw) is driven at the drive frequency f. Here, the voltage applied between the U-V phases of the AC motor 1 is called a line-to-line voltage Vuv.

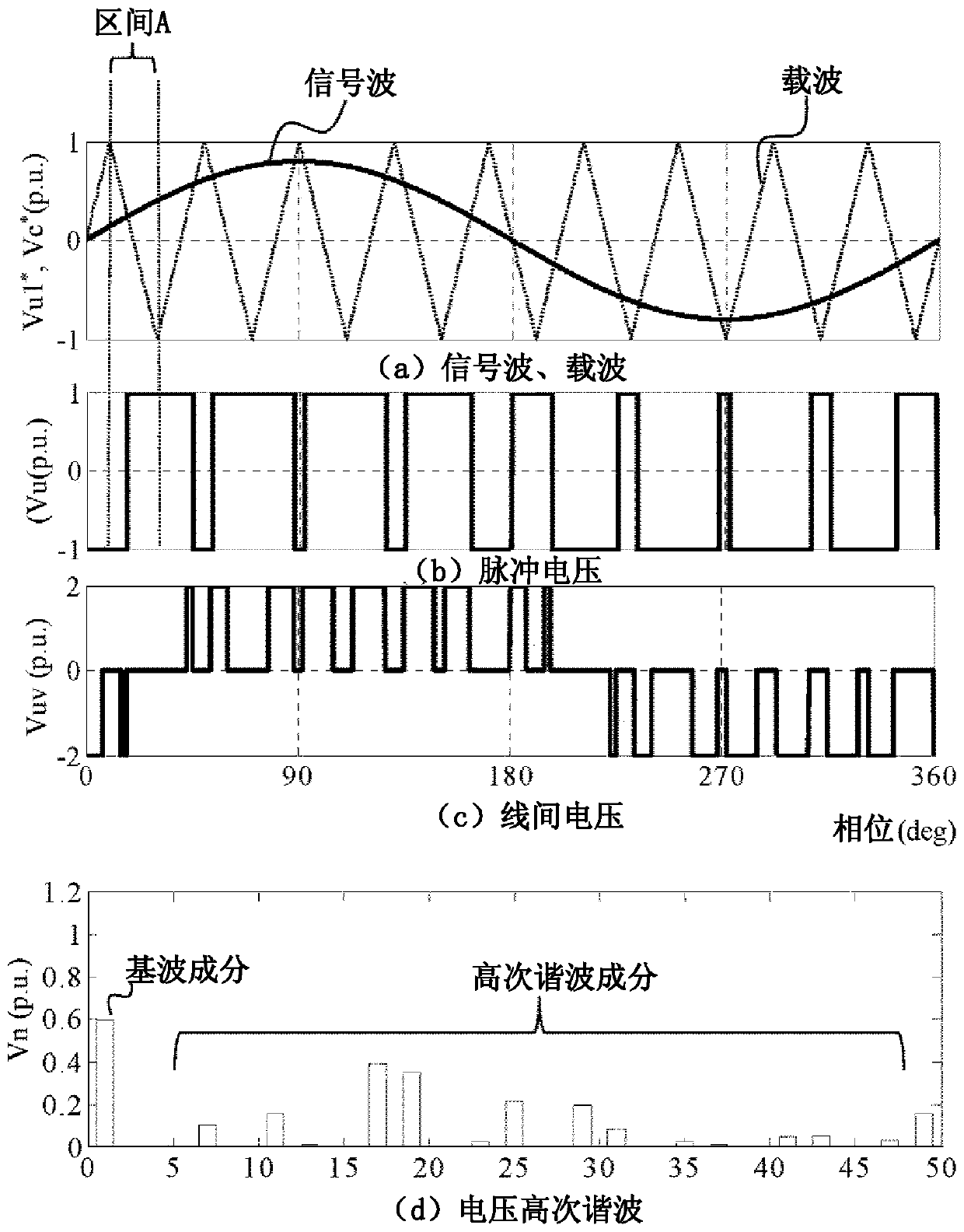

[0030] The carrier generation unit 3 generates a carrier Vc* based on the carrier frequency fc. Such as image 3 As shown in (a), the carrier Vc* is a triangular wave with amplitude 1 (normalized by half VDC / 2 of DC voltage) and frequency fc.

[0031] The signal wave generator 4 generates signal waves (U-phase signal wave Vu1 *, V-phase signal wave Vv1 *, W-phase signal wave Vw1 *) based on the frequency command f1 * and the voltage command V1 *. The signal wave is ...

Embodiment 2

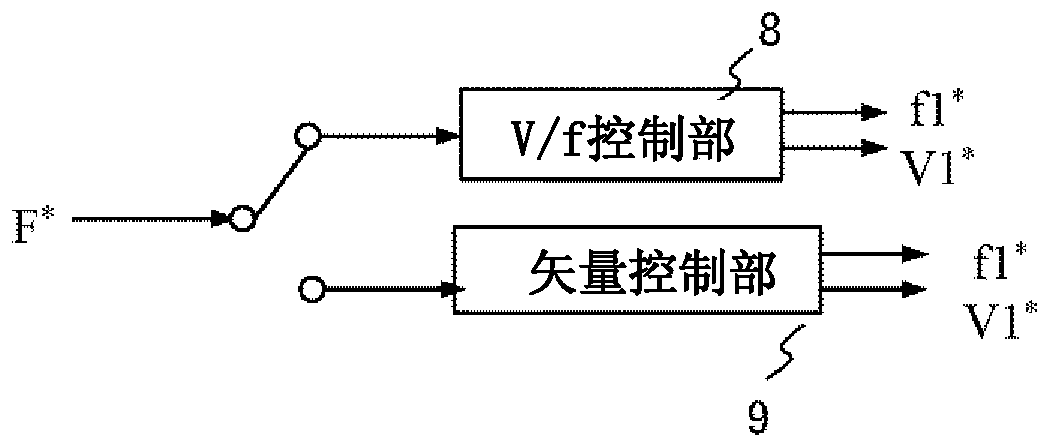

[0090] Figure 11 It is a structural diagram of Embodiment 2. This embodiment is an example in which the first embodiment is applied to the drive system of the AC motor 1 . exist Figure 11 , the description of the same parts as those in Embodiment 1 is omitted. In this embodiment, the speed command F* can be set by a higher-level device such as the computer 10 .

[0091] According to the present embodiment, high-precision speed control characteristics can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com