Power reversal control method and power reversal control device for hybrid direct-current power transmission system

A DC transmission system and power flow reversal technology, applied in the direction of power transmission AC network, etc., can solve the problems of increasing the number of switching operations of filtering or reactive power compensation equipment, poor controllability of reactive power, and voltage fluctuations of interconnected power grids, reducing Switching times, stable DC power reversal, and the effect of realizing DC power reversal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

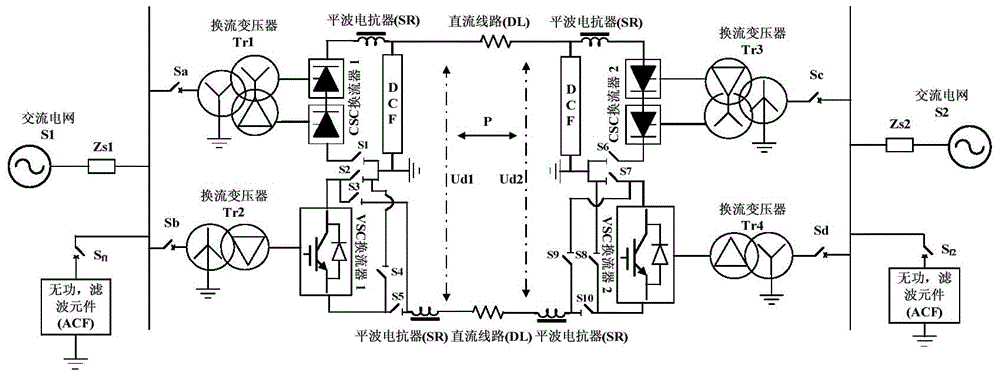

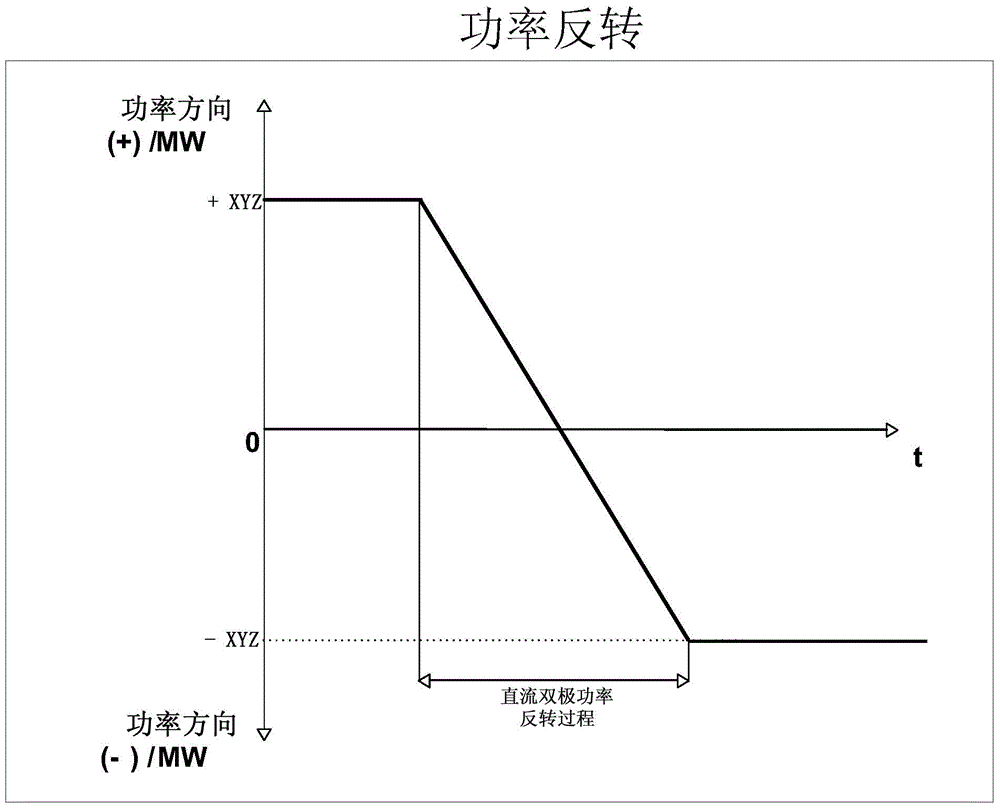

[0026] Example 1: The schematic diagram of bipolar active power changes in the process of power flow reversal is as follows figure 2 shown. The power flow reversal process of the hybrid bipolar DC transmission system specifically includes the following steps:

[0027] (1) Obtain the automatic power flow reversal start signal;

[0028] (2) Reduce the bipolar DC active power at a certain rate, and keep the bipolar DC active power linearly decreasing during the decline process, and at the same time, the net reactive power of the converter stations at both ends of the pole control based on VSC-HVDC technology is constant;

[0029] (3) After the DC current of the pole based on LCC-HVDC technology drops to the minimum current, the power will no longer drop. At this time, adjust the active power drop rate of the pole based on VSC-HVDC technology to keep the bipolar DC active power in a straight line;

[0030] (4) When the bipolar DC active power linearly decreases to an appropriat...

Embodiment 2

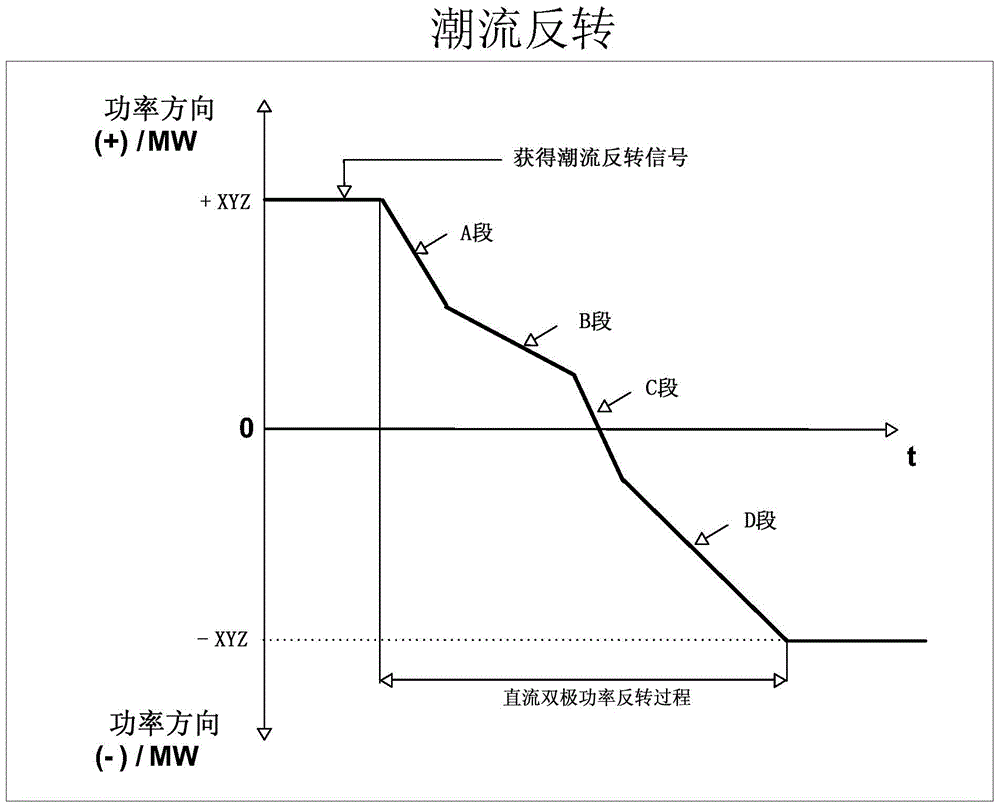

[0035] Example 2: The schematic diagram of bipolar active power changes during power flow reversal is as follows image 3 shown. The power flow reversal process of the hybrid bipolar DC transmission system specifically includes the following steps:

[0036] (1) Obtain the automatic power flow reversal start signal;

[0037] (2) Reduce the two-pole DC active power at a rate k1, such as image 3 As shown in the section A curve in , the bipolar DC active power keeps decreasing continuously during the decline process, and at the same time, the net reactive power of the converter stations at both ends of the pole control based on VSC-HVDC technology remains constant;

[0038] (3) After the DC current of the pole based on LCC-HVDC technology is reduced to the minimum current, the power will not drop, and the active power of the pole based on VSC-HVDC technology will continue to decline at the original rate, and the bipolar DC active power will continue to decline linearly; image...

Embodiment 3

[0047] Embodiment 3: The present invention also provides a device for controlling power flow reversal, such as Figure 4 As shown, the device includes a power flow reversal start judgment unit, an active power control unit, a reactive power control unit and a power flow reversal stop judgment unit, wherein

[0048] The power flow reversal start judging unit is used to collect the power flow reversal start signal, and the power flow reversal start signal is a signal or a composite signal of several signals;

[0049] The active power control unit is used to control the active power of the power flow reversal process;

[0050] The reactive power control unit is used to control the reactive power of the power flow reversal process;

[0051] The power flow reversal stop judging unit is used to collect a power flow reversal stop signal, and the power flow reversal stop signal is one signal or a composite signal of several signals.

[0052] When the power flow reversal start discri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com