3D printed humerus model and manufacturing method thereof

A 3D printing, humerus technology, applied in the direction of bone implants, computer-aided planning/modeling, medical science, etc., can solve the problems of poor recovery, insufficient targeted and personalized treatment methods, and achieve intuitive and simple communication. The effect of shortened operation time and precise operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

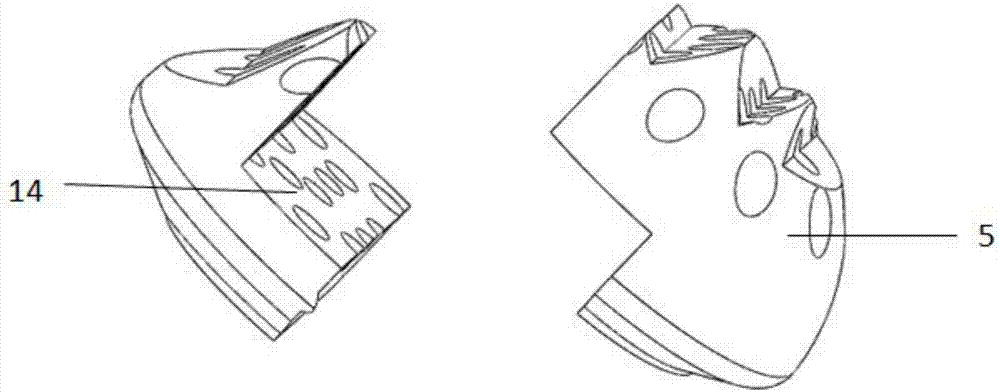

[0039] Embodiment 1 A kind of preparation method of the humerus model of 3D printing

[0040] The images and data of the humerus and fracture on both sides of the patient were obtained through 64-slice spiral CT scanning; the data were imported into the computer for analysis, and the humerus on both sides was analyzed. Through adjustment and analysis, the humerus on the non-fracture side and the humerus on the fracture side were mirror-symmetrical. Mirror the humerus on the non-fracture side, so as to obtain a complete three-dimensional mirror image humerus 6 consistent with the fracture side humerus; analyze the fracture surface 14 and the size of the bone fragment 5 at the fracture, and generate a three-dimensional fracture surface 14 and bone fragment 5; The three-dimensional image of the mirror image of the humerus 6 and the three-dimensional images of the fractured bone and its fracture surface 14 and the bone fragment 5 are placed side by side, and the fracture surface 14...

Embodiment 2

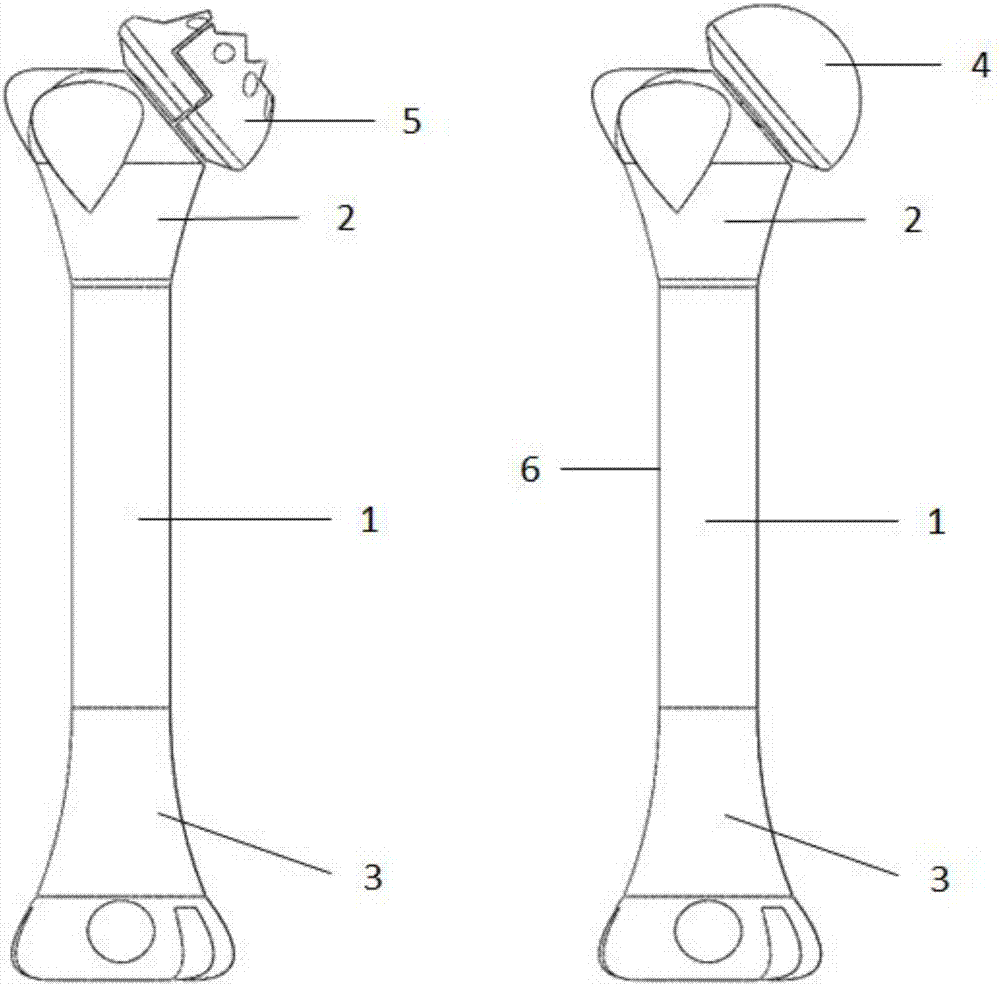

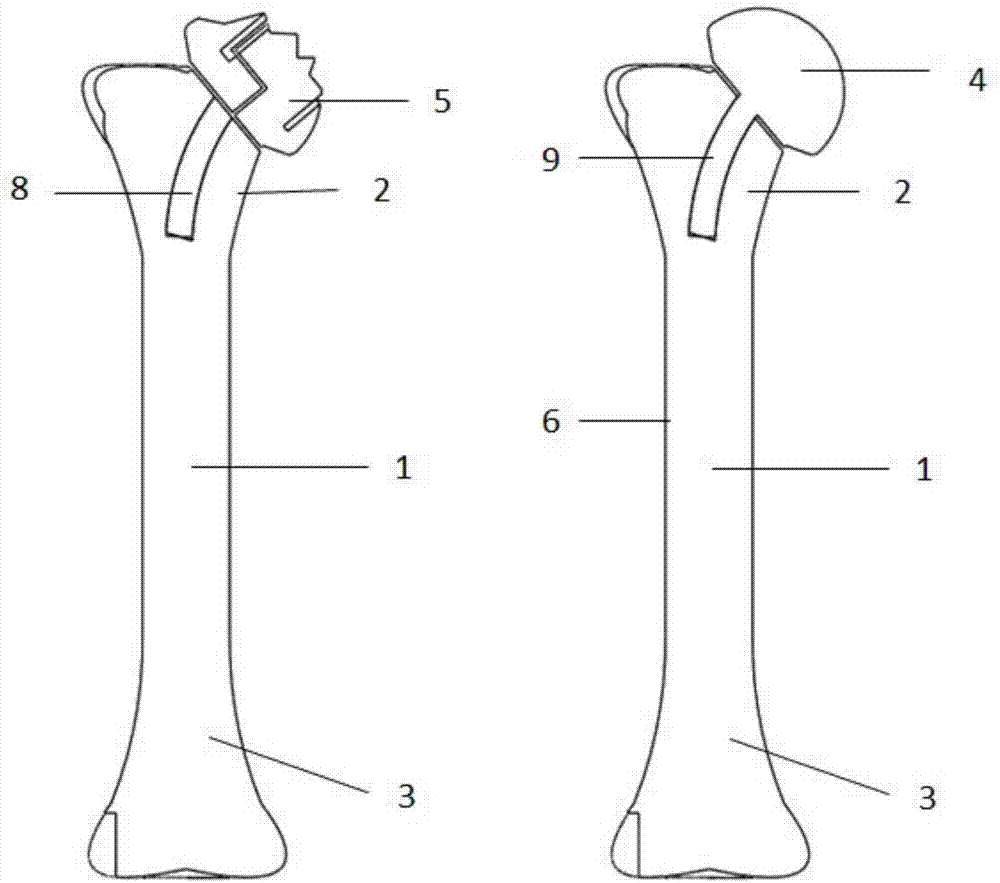

[0043] Embodiment 2 A kind of humerus model of 3D printing

[0044]A 3D printed humerus model, which includes a humerus shaft 1, a humerus proximal end 2, a humerus distal end 3, a fracture surface 14 and / or 10 bone fragments 5; wherein the humerus model also includes a 3D printed fractured humerus pair The mirror humerus 6 structure of the lateral humerus, when the fracture surface 14 is at the humeral head 4 and replacement of the humeral head 4 is required, a cross section 7 is set under the fracture surface 14, and the humeral head rod entry hole 8 is set under the cross section 7; the mirror image of the humerus 6 structure corresponds to a cross-section 7, which divides the mirrored humerus 6 into two parts, one part is the upper humeral head 4 structure, the lower part is the humeral shaft 1 structure, and the humeral head rod 9 is set at the cross-section 7 of the humeral head 4 structure . The setting of the cross section 7, the humeral head rod entry hole 8 and the ...

Embodiment 3

[0045] Embodiment 3 A kind of humerus model of 3D printing

[0046] A 3D printed humerus model, which includes a humerus shaft 1, a humerus proximal end 2, a humerus distal end 3, a fracture surface 14 and / or 10 bone fragments 5; wherein the humerus model also includes a 3D printed fractured humerus pair The mirror humerus 6 structure of the lateral humerus, when the fracture surface 14 is at the humeral head 4 and replacement of the humeral head 4 is required, a cross section 7 is set under the fracture surface 14, and the humeral head rod entry hole 8 is set under the cross section 7; the mirror image of the humerus 6 structure corresponds to a cross-section 7, which divides the mirrored humerus 6 into two parts, one part is the upper humeral head 4 structure, the lower part is the humeral shaft 1 structure, and the humeral head rod 9 is set at the cross-section 7 of the humeral head 4 structure . The setting of the cross section 7, the humeral head rod entry hole 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com