Load-type copper oxide-based catalyst containing auxiliary agent and preparation method thereof

A catalyst, copper oxide technology, used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low yield, etc. Stable and easy to recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

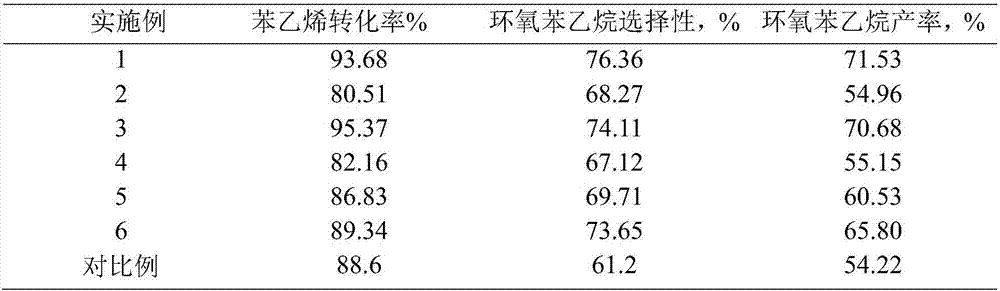

Embodiment 1

[0019] A. Weigh 15mmolCo(NO 3 ) 2 ·6H 2 O and 5mmolAl(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to prepare solution A, and weighed 10mmolNa 2 CO 3 Dissolve 30mmol NaOH in 100ml deionized water to prepare solution B, add solution A and solution B dropwise to the four-neck flask at room temperature, keep the pH at 10, keep the suspension in a water bath at 80°C for 18h after the addition, and naturally Cool to room temperature; the resulting precipitate was washed with deionized water and centrifuged until neutral, and the filter cake was dried overnight in an oven at 60°C to obtain Co 3 al 1 -LDH.

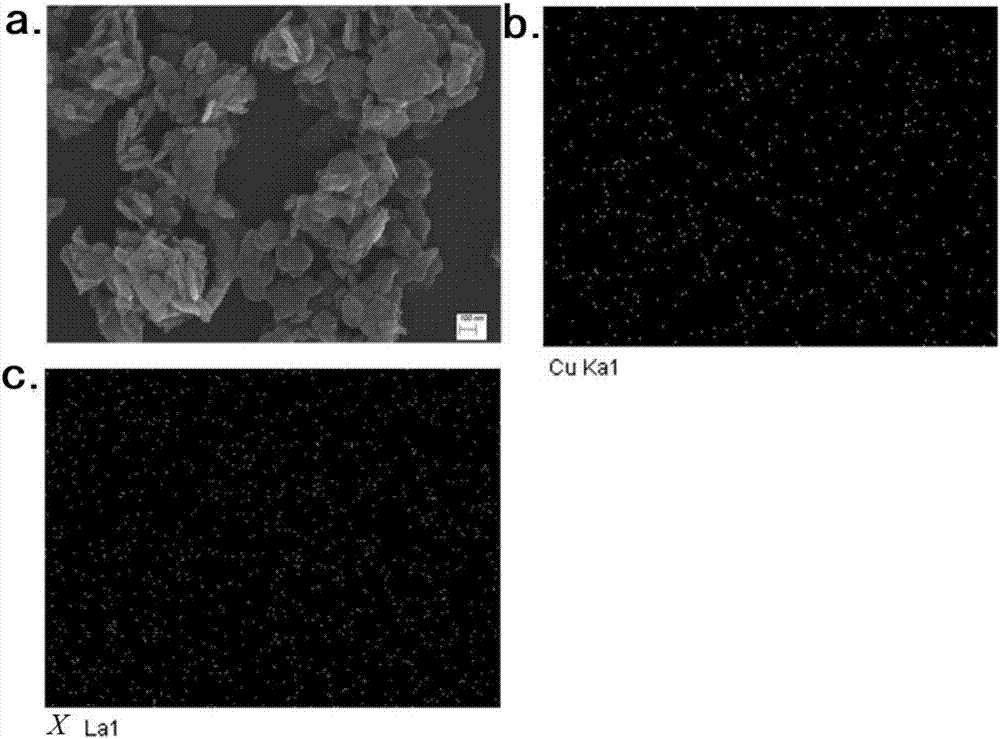

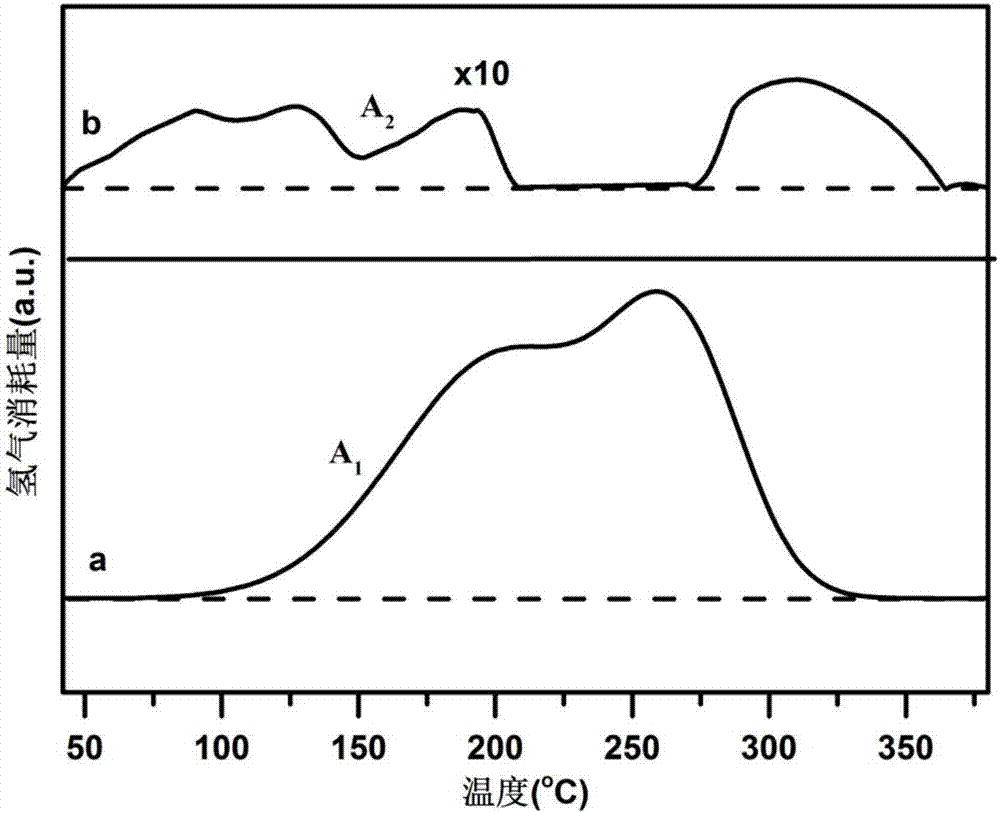

[0020] B. Take 0.3gCo 3 al 1-LDH carrier was placed in 40ml deionized water and stirred to form a uniform suspension, and the pH was adjusted to 10 with a NaOH solution with a concentration of 1mol / L, and 0.0273g Cu(NO 3 ) 2 +3H 2 O with 0.0147g Ce(NO 3 ) 3 +6H 2 O was added to the suspension, stirred in a water bath at 85°C for 6 hours, the obtained pre...

Embodiment 2

[0022] A. Weigh 10mmolCo(NO 3 ) 2 ·6H 2 O and 5mmolAl(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to prepare solution A, and weighed 5mmolNa 2 CO 3 and 20mmol NaOH were dissolved in 100ml deionized water to prepare solution B, and solution A and solution B were added dropwise to the four-neck flask at room temperature, keeping the pH at 11, and the suspension after the addition was kept in a water bath at 80°C for 24h, and naturally Cool to room temperature; the resulting precipitate was washed with deionized water and centrifuged until neutral, and the filter cake was dried overnight in an oven at 60°C to obtain Co 2 al 1 -LDH.

[0023] B. Take 0.3gCo 2 al 1 -LDH carrier was placed in 40ml deionized water and stirred to form a uniform suspension, and the pH was adjusted to 11 with a NaOH solution with a concentration of 1mol / L, and 0.0273g Cu(NO 3 ) 2 +3H 2 O with 0.0066g Ni(NO 3 ) 2 +6H 2 O was added to the suspension, stirred in a water bath at 85...

Embodiment 3

[0025] A. Weigh 15mmolCo(NO 3 ) 2 ·6H 2 O and 5mmolAl(NO 3 ) 3 9H 2 O was dissolved in 100ml deionized water to prepare solution A, and weighed 10mmolNa 2 CO 3 and 30mmol NaOH were dissolved in 100ml deionized water to prepare solution B, and solution A and solution B were added dropwise to the four-necked flask at room temperature, keeping the pH at 9, and the suspension after the addition was kept in a water bath at 80°C for 18h, and naturally Cool to room temperature; the resulting precipitate was washed with deionized water and centrifuged until neutral, and the filter cake was dried overnight in an oven at 60°C to obtain Co 3 al 1 -LDH.

[0026] B. Take 0.3gCo 3 al 1 -LDH carrier was placed in 40ml deionized water and stirred to form a uniform suspension, adding urea with a concentration of 1mol / L to adjust the pH to 11, and 0.0273g Cu(NO 3 ) 2 +3H 2 O with 0.0049g Ce(NO 3 ) 3 +6H 2 O was added to the suspension, stirred in a water bath at 85°C for 8 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com