Glass tube cleaning device

A cleaning device and glass tube technology, applied in the direction of cleaning hollow objects, cleaning flexible objects, cleaning methods and utensils, etc., can solve problems such as low efficiency, air bubbles, and affecting the measurement accuracy of sphygmomanometers, and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

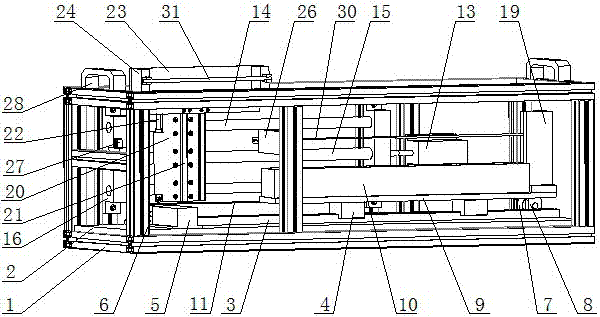

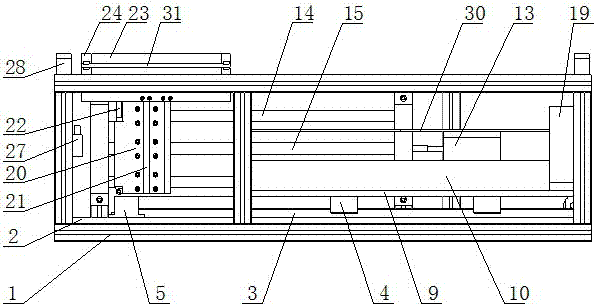

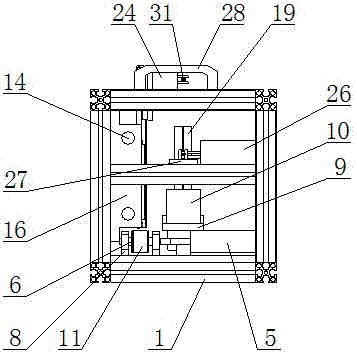

[0025] See Figure 1-5 , A glass tube cleaning device, which is characterized by: comprising a frame 1, a platform bottom plate set on the frame 1, a movable platform guide rail 3, a movable platform guide rail slider 4, and a mobile platform set on the platform bottom plate 2. The moving mechanism composed of the motor 5, the moving platform board 9, the synchronous belt 11, the synchronous belt driving axle 6, the synchronous belt driven axle 7 and the synchronous belt axle support 8, is arranged on the frame 1 by the horizontal movement motor 13, horizontal The traverse mechanism composed of the light-shifting rod 14, the traverse screw 15, the screw nut 18, the polished rod slider 17, the polished rod seat 16 and the traverse platform plate 20, is provided on the traverse platform plate 20 by the lifting guide rail 21, lifting The lifting mechanism composed of the air cylinder 22, the lifting rail slider 25 and the lifting platform plate 23, the glass tube air claw 24 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com