Equipment for automatically adhering non-woven fabrics to shells

A non-woven fabric and shell technology, applied in the field of automatic assembly equipment, can solve the problems of manual fitting and shaping, difficult to unify quality standards, low production efficiency, etc., and achieve ingenious structural design, high production efficiency, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

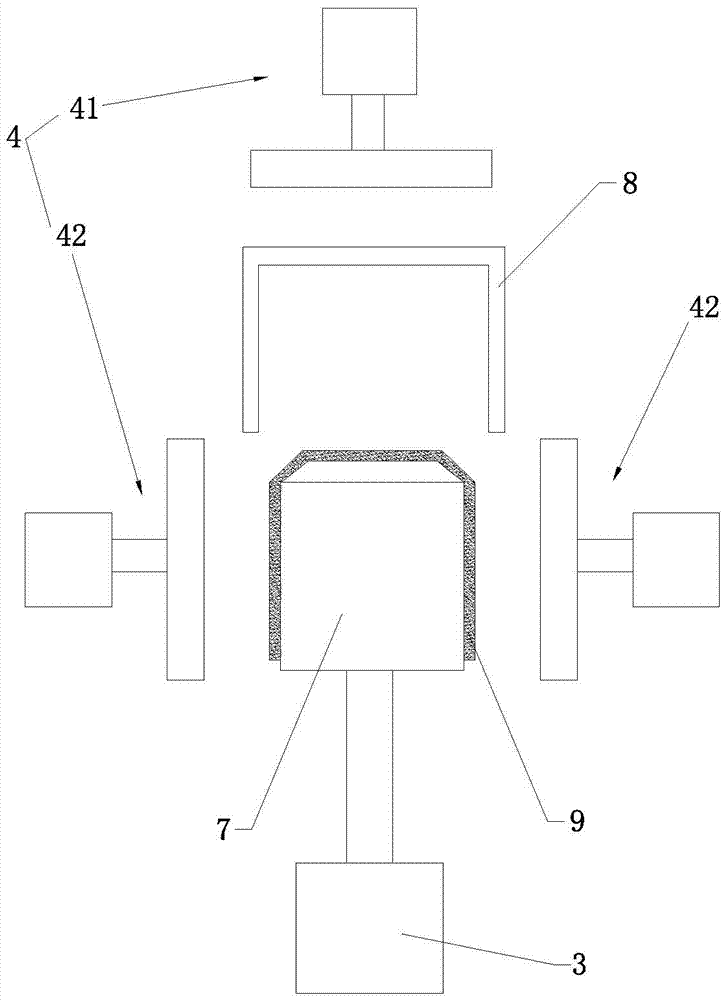

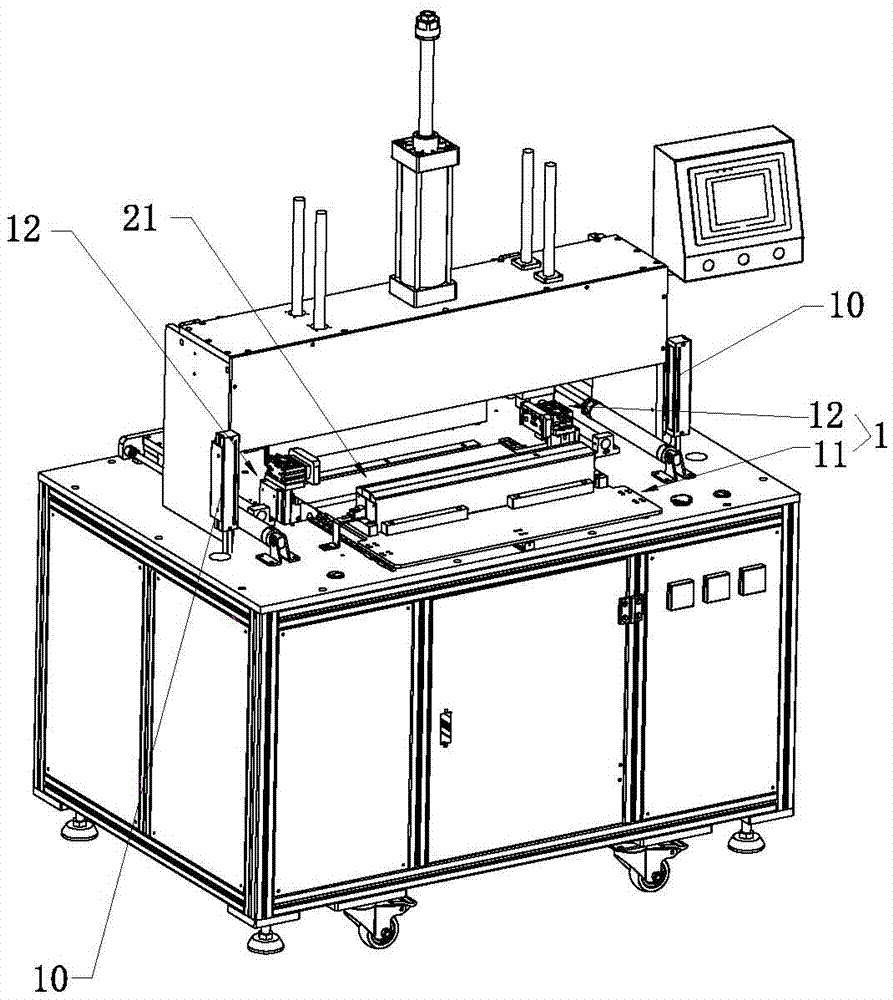

Method used

Image

Examples

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 12 , the hot pressing device 4 includes a hot pressing cover 43 and a hot pressing cover driving device 44 for driving the displacement of the hot pressing cover 43, the hot pressing cover 43 is arranged above the patch bottom mold 7, the hot pressing cover 43 is provided with the cavity that matches with housing. When the casing is hot-pressed, the heat-press cover driving device 44 drives the heat-press cover 43 to move toward the casing, so that the casing is inserted into the concave cavity of the heat-press cover 43 for heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com