Damping system for complete communication-in-motion equipment by adopting external wire ropes

A shock absorption system and wire rope technology, applied in the direction of engine base, spring/shock absorber, shock absorber, etc., can solve the problems of high impact conditions, high cost, and troublesome assembly, and achieve the reduction of equipment structure design and selection of models. Reduced requirements and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

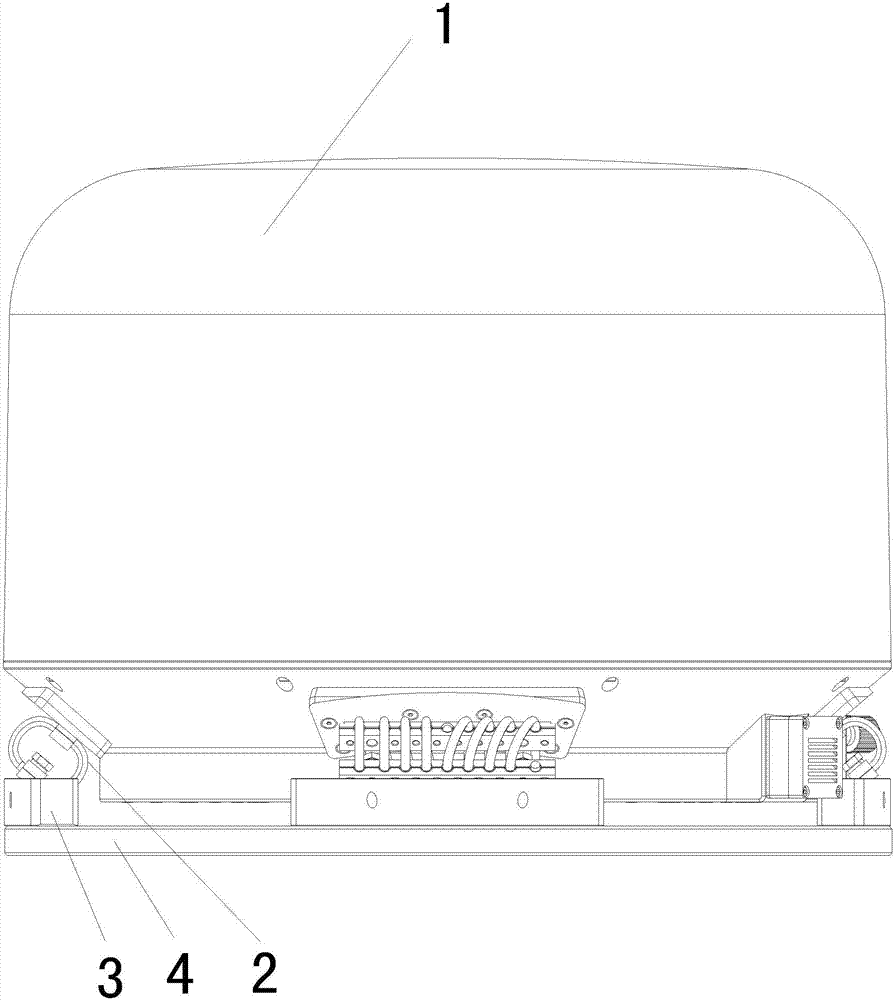

[0028] like image 3 As shown, the shock absorbing system for the whole machine in motion using an external steel wire rope 23 includes a device fixing plate 4 for bearing gravity as a whole; includes a plurality of shock absorbers that use the elasticity of the steel wire rope 23 as a buffer for the impact force of the communication device 1 2. It includes a plurality of adapters 3 for installing the shock absorber 2; the plurality of adapters 3 are evenly installed on the equipment fixing plate 4 in a circle, and the upper part of each adapter 3 is fixedly connected with a shock absorber The first end of the shock absorber 2, the shock absorber 2 is installed at an angle of 45° to the vertical direction, and the second end of the shock absorber 2 is fixedly connected with the Zhongtong equipment 1.

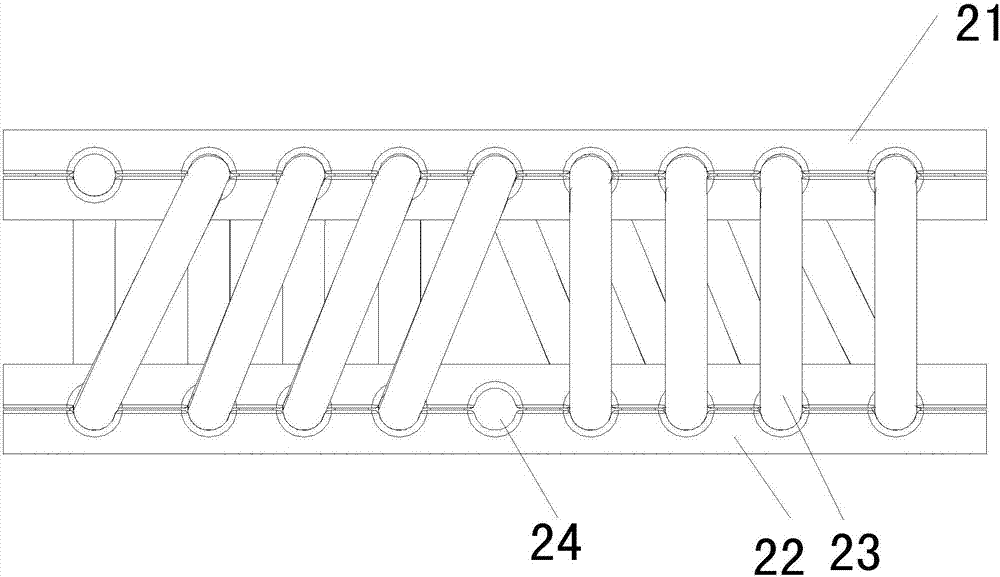

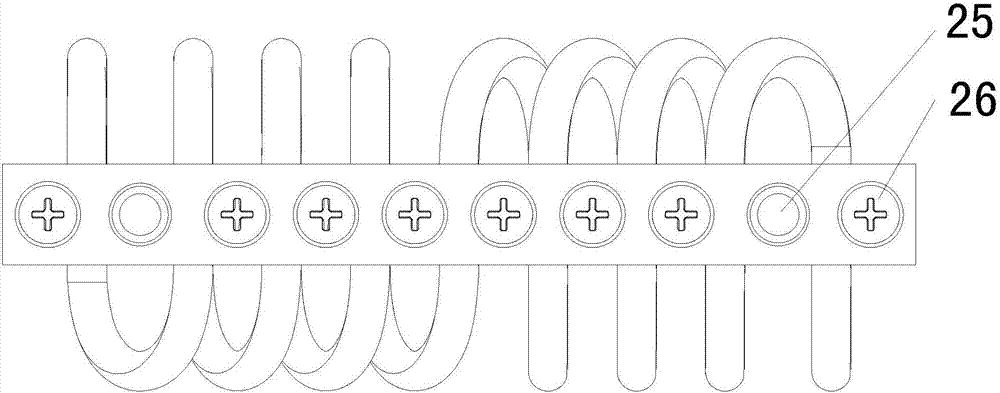

[0029] like figure 1 , figure 2 As shown, each shock absorber 2 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com