Ultrahigh temperature multi-dimensional multi-functional strain measurement system based on ultraviolet imaging DIC and measurement method

A strain measurement and ultraviolet imaging technology, which is applied in the field of ultra-high temperature displacement and strain measurement, can solve the problems of high accuracy, fast calculation speed, and cannot meet the needs of ultra-high temperature multi-scale and multi-functional strain measurement, and achieves high accuracy and improved measurement. Accuracy, effect of improving strain measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

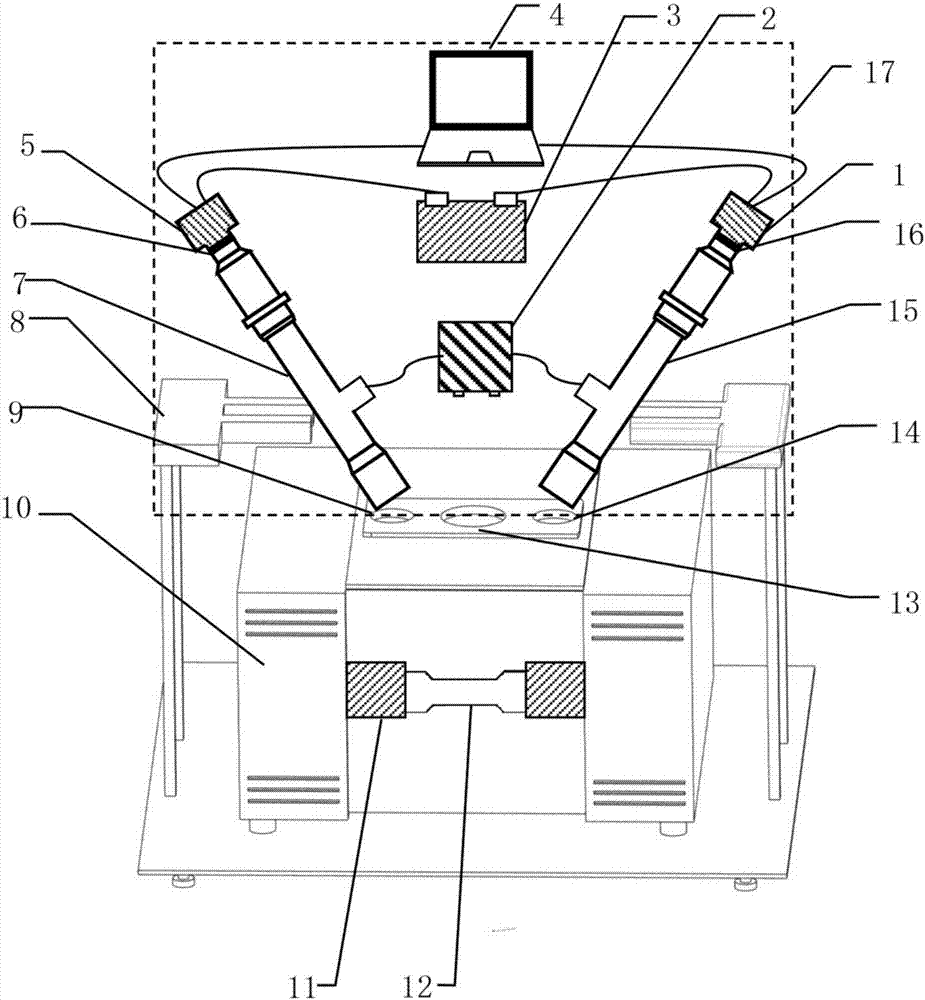

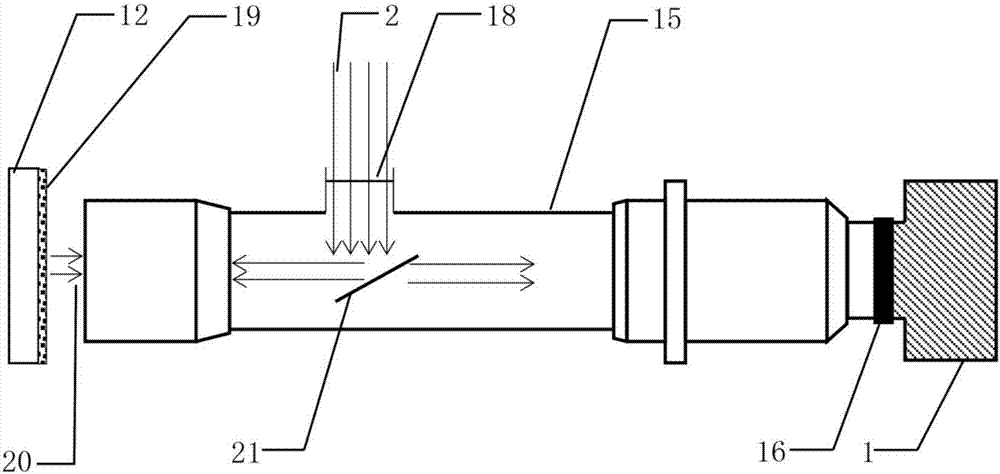

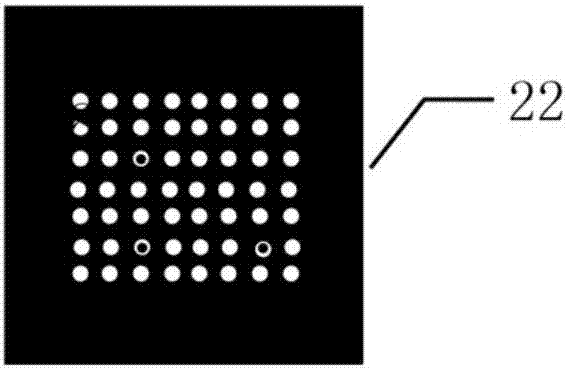

[0033] An ultra-high temperature multi-scale multifunctional strain measurement system and measurement method based on ultraviolet imaging DIC, including: a coaxial microscopic imaging system 17, a mechanical support adjustment platform 8, a monochromatic light source 2, and a narrow band corresponding to the wavelength of the monochromatic light source Pass filters 6 and 16, ultraviolet cameras 1 and 5, computer 4; coaxial microscopic imaging system 17 is used to collect clear images of the image surface through the optical sapphire glass observation window under ultra-high temperature conditions; mechanical support adjustment platform 8 It is used to support the coaxial microscopic imaging system 17. By adjusting the mechanical support adjustment platform 8, it can realize the adjustment of three directions in space and three angles with a total of six degrees of freedom, thereby adjusting the optical axis of the coaxial microscopic imaging system 5 and The area of interest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com