Online loose body density measurement method and device

A technology of loose body and density, which is applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of reducing production efficiency, increasing the workload and working time of operators, and cracking the furnace core tube, so as to reduce the working load and working time , Avoid the scrapping of the furnace core tube, and ensure the effect of stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] An embodiment of the present invention provides a method for online measurement of bulk density, which is suitable for manufacturing optical fiber preforms by VAD method, including the following steps:

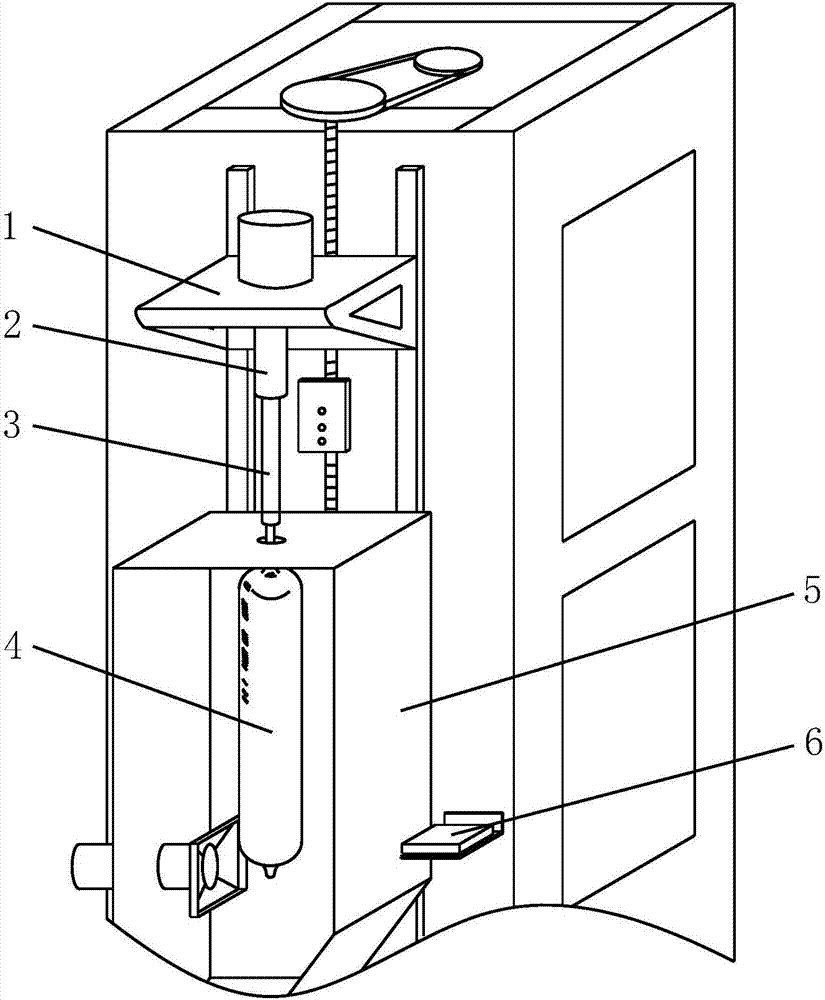

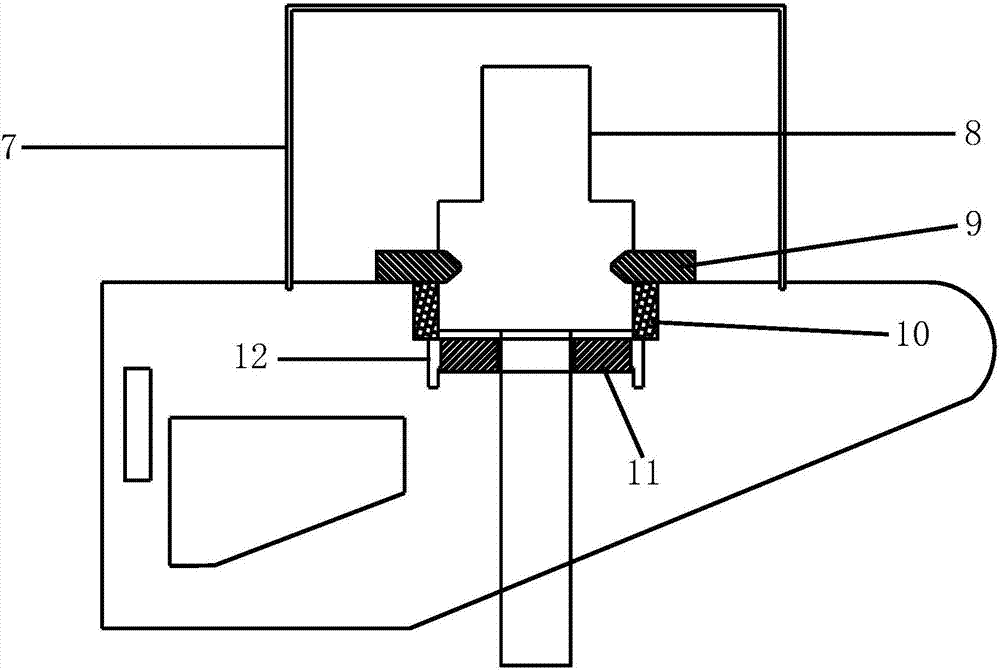

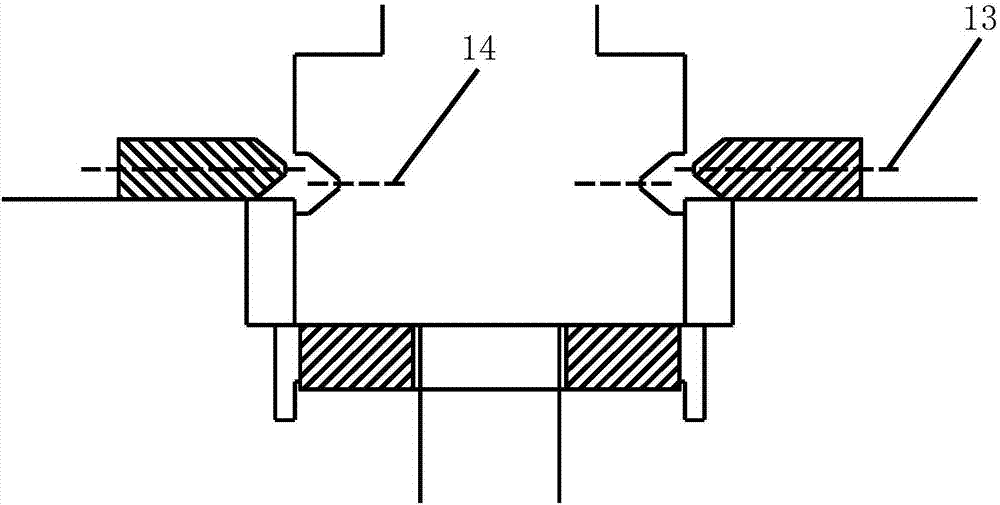

[0049] see figure 1 , figure 2 As shown, the VAD equipment includes a lifting platform 1, a rotating guide rod 2, a rotating motor 8, a deposition guide rod 3, and a deposition chamber 5. First, the outer diameter scanner 6 is fixed outside the deposition chamber 5, and its height is higher than that of the deposition chamber. The initial position is 10-100mm, such as 30mm; then fix the pneumatic locking chuck 9 and the ring-type load cell 11 in the bottom groove of the lifting platform 1; then place the rotating motor 8 on the ring-type load cell 11 and adjust the rotating guide rod 2 so that the rotating guide rod 2 is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com