Microreactor adopting metal and transparent plastic composite structure and application of microreactor

A micro-reactor, transparent plastic technology, applied in the field of micro-chemical industry, can solve the problems of low mass transfer and heat transfer coefficient, large volume, affecting analysis results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

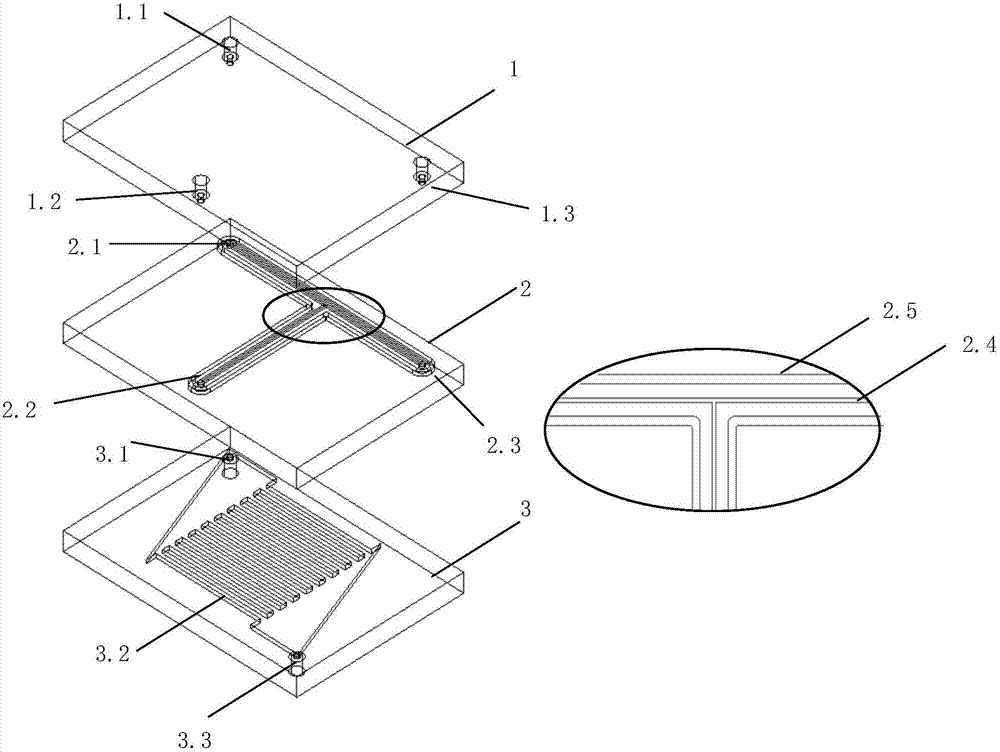

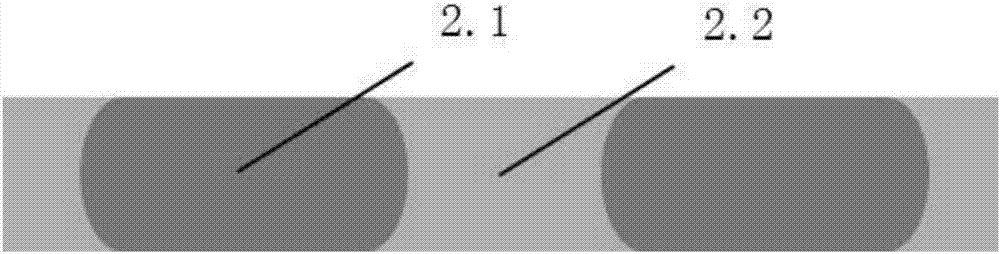

[0028] like figure 1 The microreactor with the composite structure of metal and transparent plastic as shown includes transparent plate, reaction microchannel plate and heat exchange channel plate; the material of the transparent plate is PMMA, which is made by machining, and the plate is provided with feeding holes 1.1 and 1.3 And the discharge hole 1.2; the material of the reaction microchannel plate is 316 stainless steel, which is made by machining, and the plate is engraved with a T-shaped microchannel 2.4 and a groove 2.5 around the corresponding fluid channel, and the groove is sealed by a PTFE gasket; A multi-stage heat exchange channel 3.2 is machined on the heat exchange channel plate, and the heat exchange channel inlet and outlet 3.1 and 3.3 are provided on the plate. The material of the heat exchange channel plate is stainless steel.

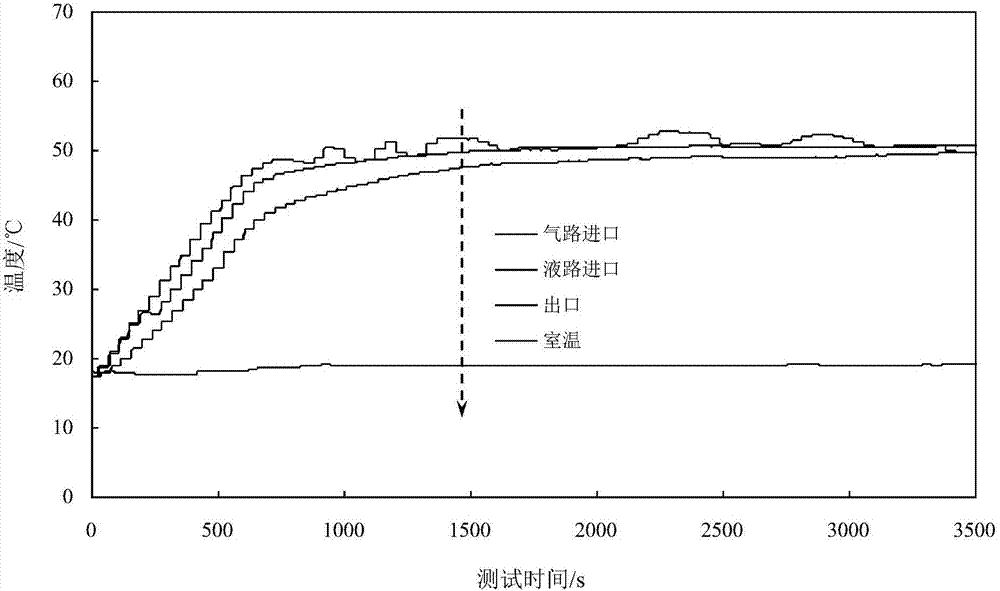

[0029] Through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com