Silk-screen printing method for obtaining arc light effect

A technology of silk screen printing and arc light, which is applied in the direction of printing and printing devices, etc., can solve the problems of ineffective silk screen printing, drop-off of screen dot matrix images, and lack of three-dimensional gradient patterns, etc., and achieve the effect of filling stillness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] refer to Figure 1 to Figure 5 .

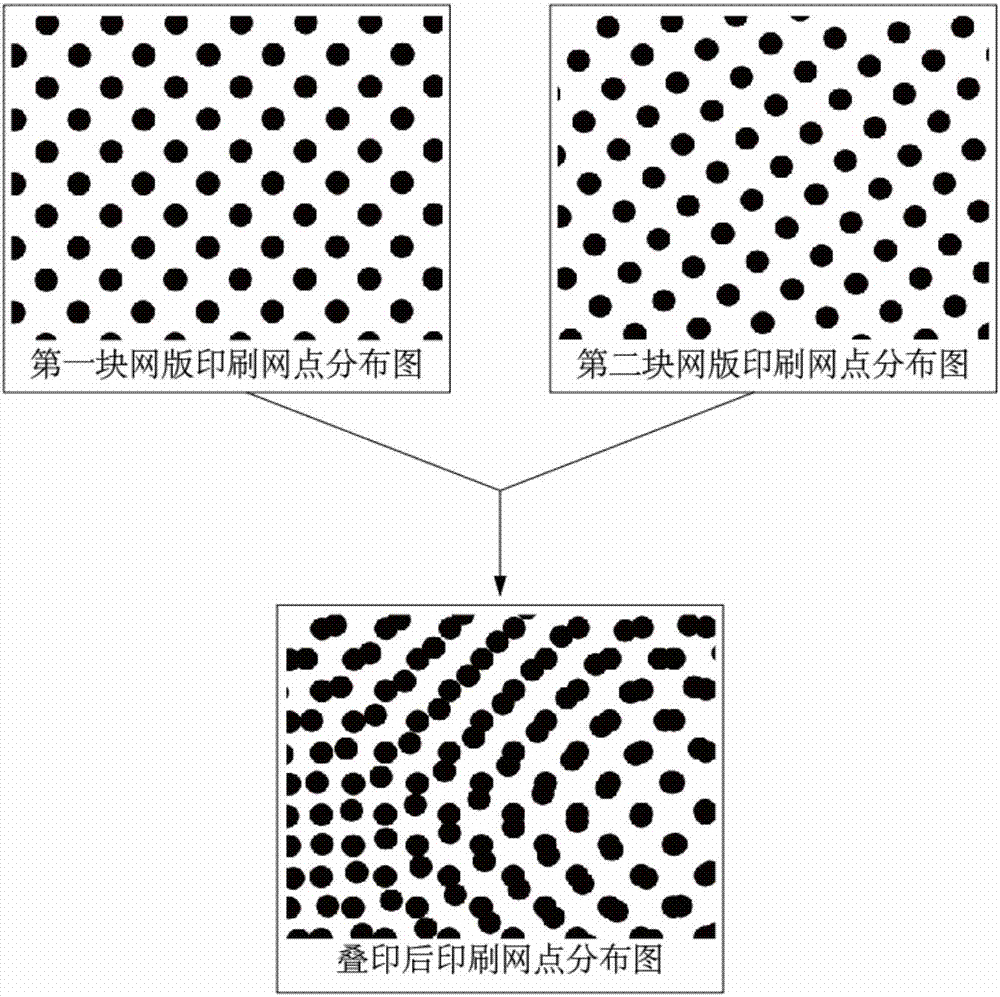

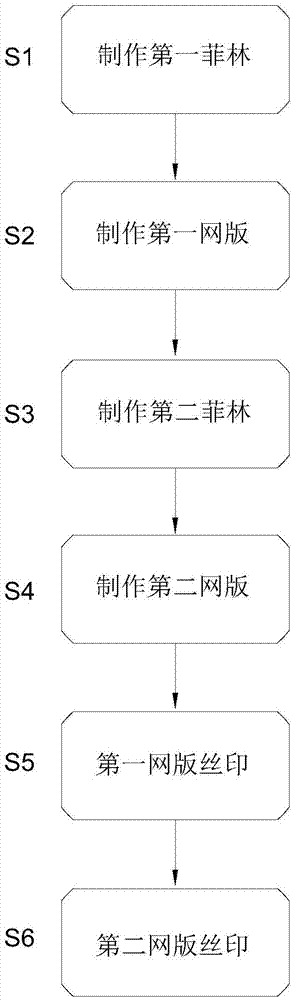

[0024] The embodiment of the present invention discloses a screen printing method with an arc light effect, such as image 3 shown, including the following steps:

[0025] S1. Make the first film, design the pattern through the computer program, and then output the first film with the designed pattern with a certain density and angle of dots through the film output system;

[0026] S2, making the first screen, pressing the first film obtained in S1 on the screen frame, coating an appropriate amount of photosensitive glue on the printing surface of the screen, performing printing and printing, and obtaining the first screen;

[0027] S3, making the second fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com