Double-auger pulse uniformly-mixing feed machine

A double auger and feeder technology, applied in mixers, conveyors, dissolution, etc., can solve the problems of general mixing effect and inapplicable mixing requirements, etc., and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

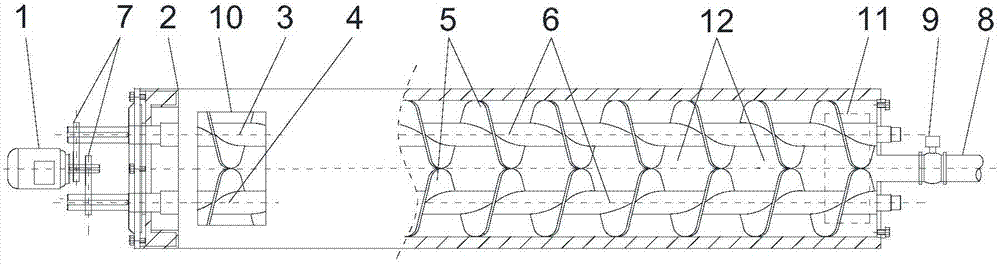

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 , a double auger pulse mixing feeder according to the present invention, comprising a motor 1, a box body 2, a first auger 3 and a second auger 4, the first auger 3 and the second auger 4 is the same size auger with the opposite rotation direction of the helical blade 5, and the length of the auger is ≤15m, so as to prevent excessive power consumption and fragile equipment due to long conveying distance. The first auger 3 and the second auger 4 are horizontally arranged side by side inside the box body 2; the rotation shaft 6 of the first auger 3 and the second auger 4 protrudes from the head end surface of the box body 2, and the motor 1 is set Between the protruding parts of the two rotating shafts 6, the motor 1 drives the first auger 3 and the second auger 4 to rotate in the same direction through the chain 7; the first auger 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com