A photoelectric automatic docking device for tire crane cable reel

A cable reel, automatic docking technology, applied in the connection/disconnection of connection devices, optics, light guides, etc., can solve the problems of inconvenient use, low efficiency, and high protection requirements, saving time, improving transmission efficiency, and avoiding optical fibers. Effects of head pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

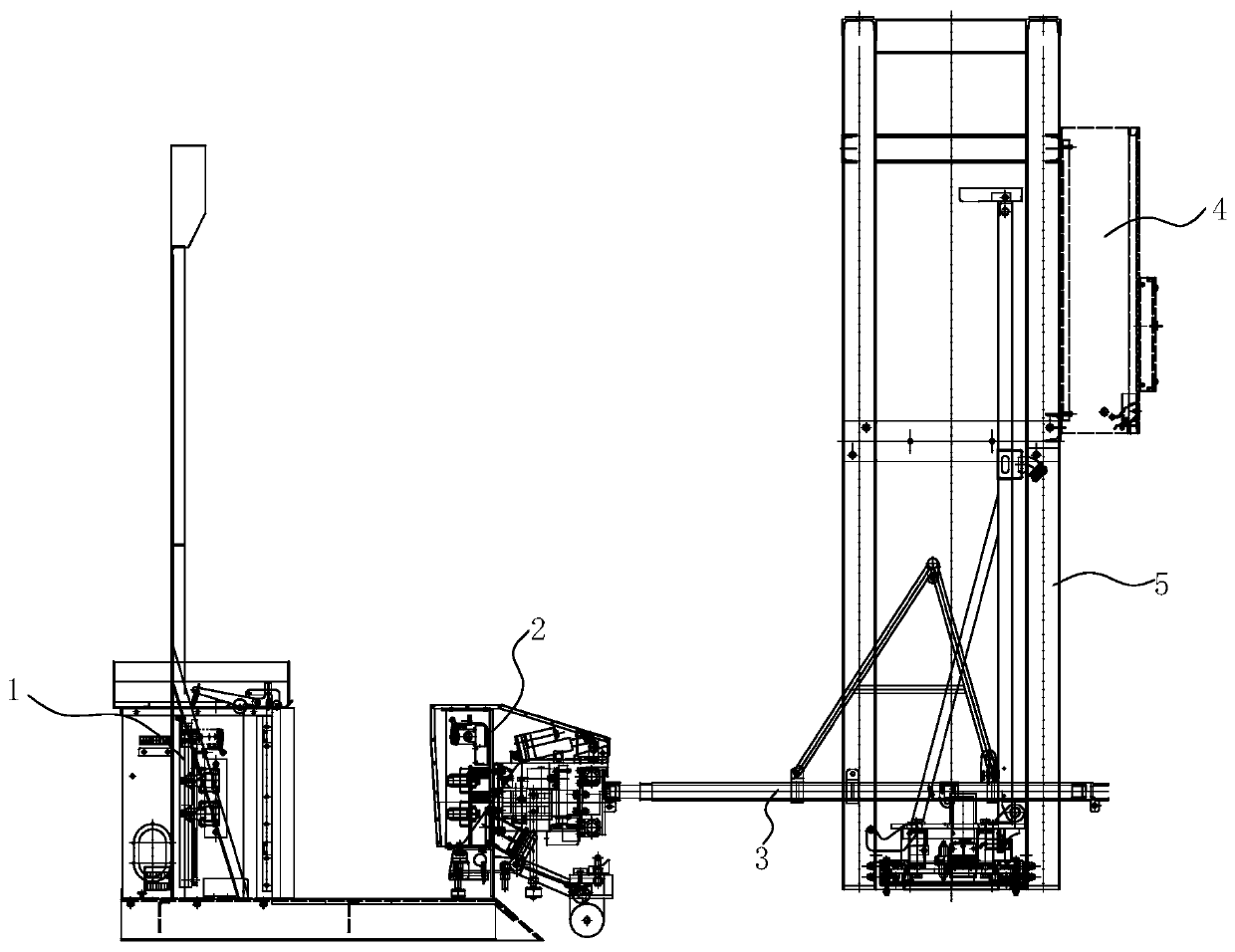

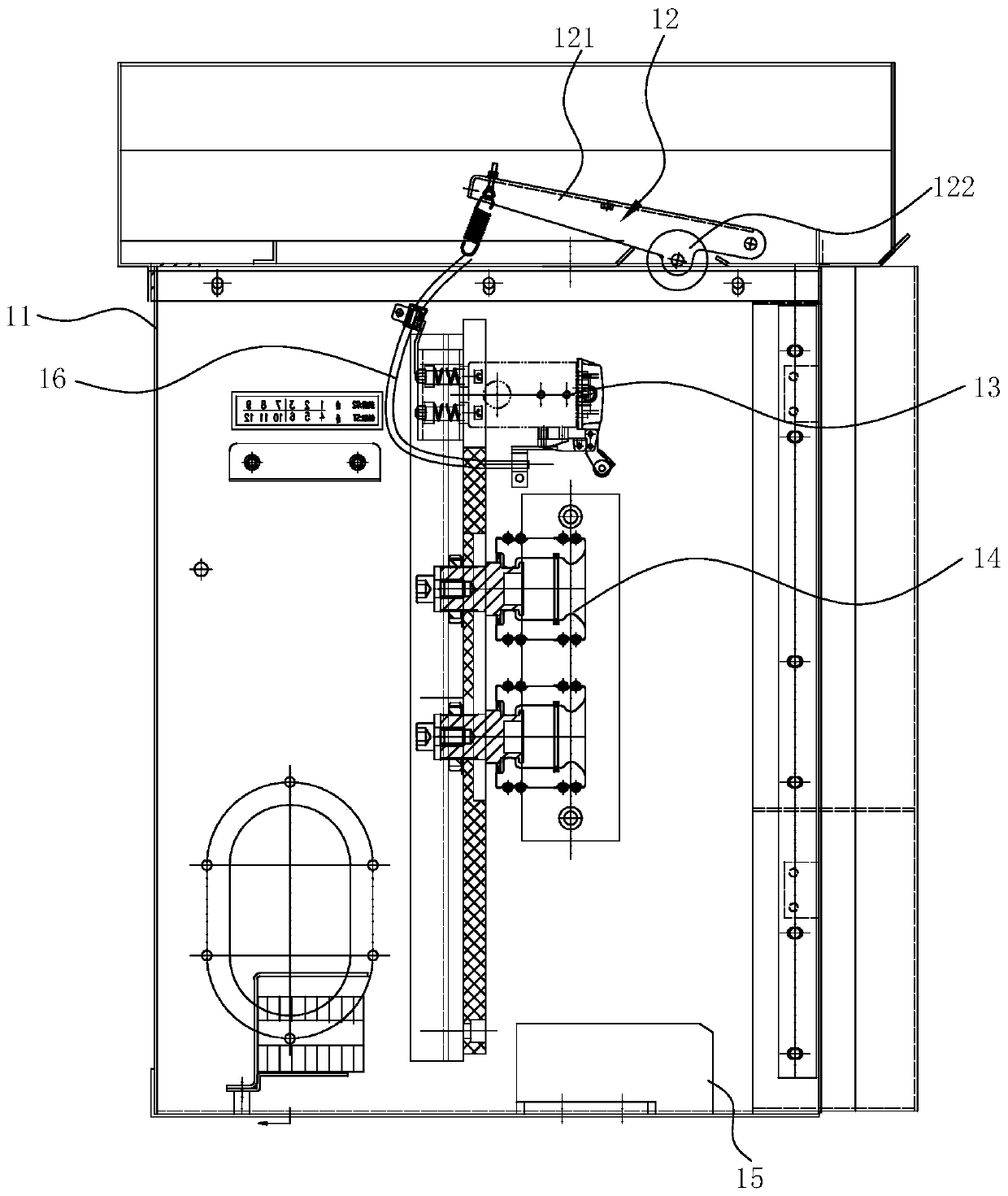

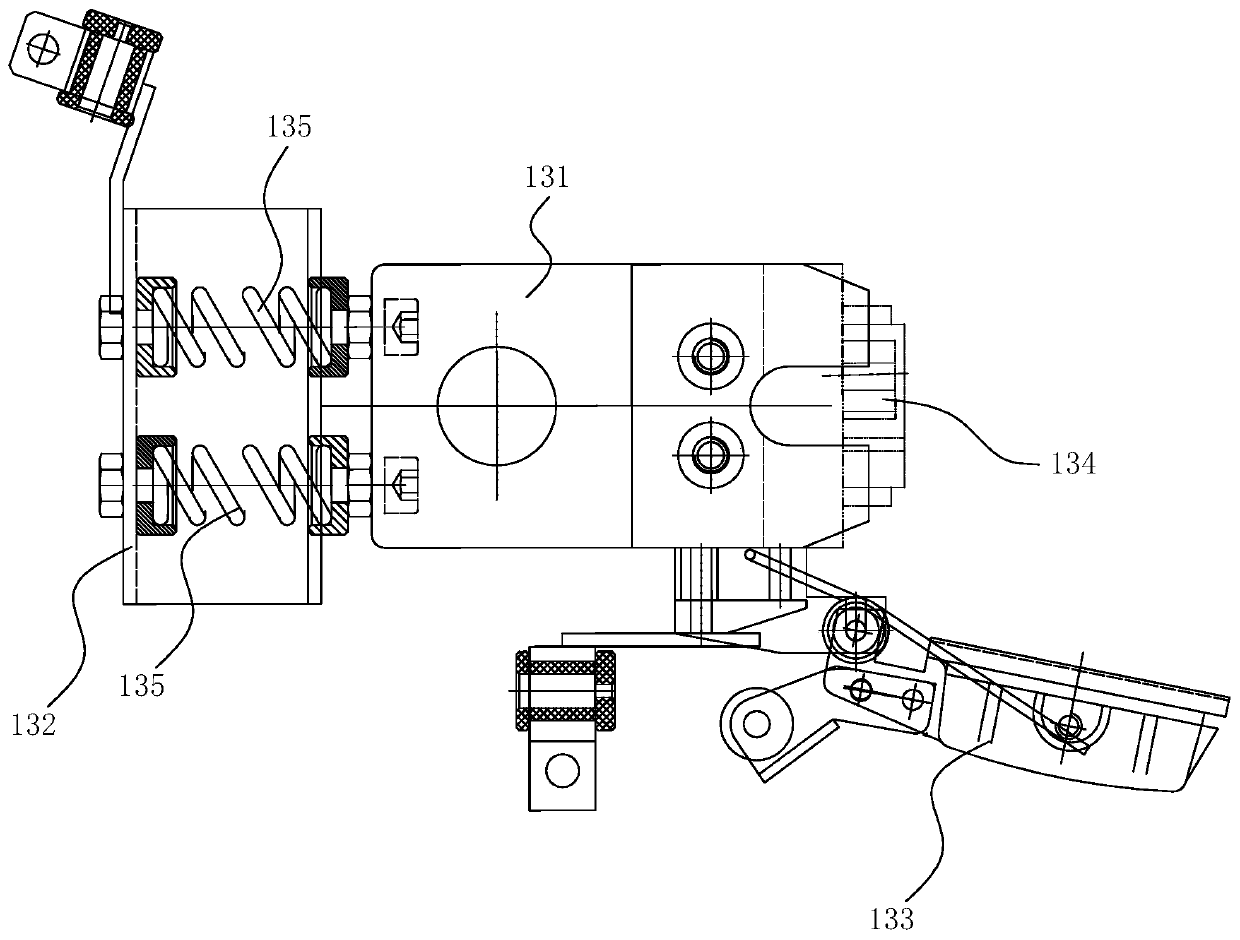

[0025] see figure 1 , a tire crane cable reel photoelectric automatic docking device, including a socket box 1, a plug box 2 matched with the socket box 1, wherein the socket box 1 is fixed on the ground, and connected to the mains and optical fiber, and the plug box 2 is Installed on the tire crane, the tire crane 5 is provided with a manipulator 3 and an electric control box 4, and the plug box 2 is connected to the outer end of the manipulator 3, and is inserted into the socket box 1 on the ground through the expansion and contraction or swing of the manipulator 3 to connect with the mains and the mains. Optical fiber connection, the inner end of the manipulator 3 is hinged on the tire crane 5, and the electric control box 4 is used to control the motion of the manipulator 3. For the structure of the manipulator 3, reference may be made to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com