Medical molecular sieve oxygen generation system pretreatment device

A technology of pretreatment device and oxygen production system, which is applied in the field of medical equipment, can solve the problems of high cost of oxygen production, easy pulverization and adsorption efficiency of molecular sieves, etc., and achieve the goal of reducing refrigeration power consumption and calorific value, prolonging the capacity, and improving the capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

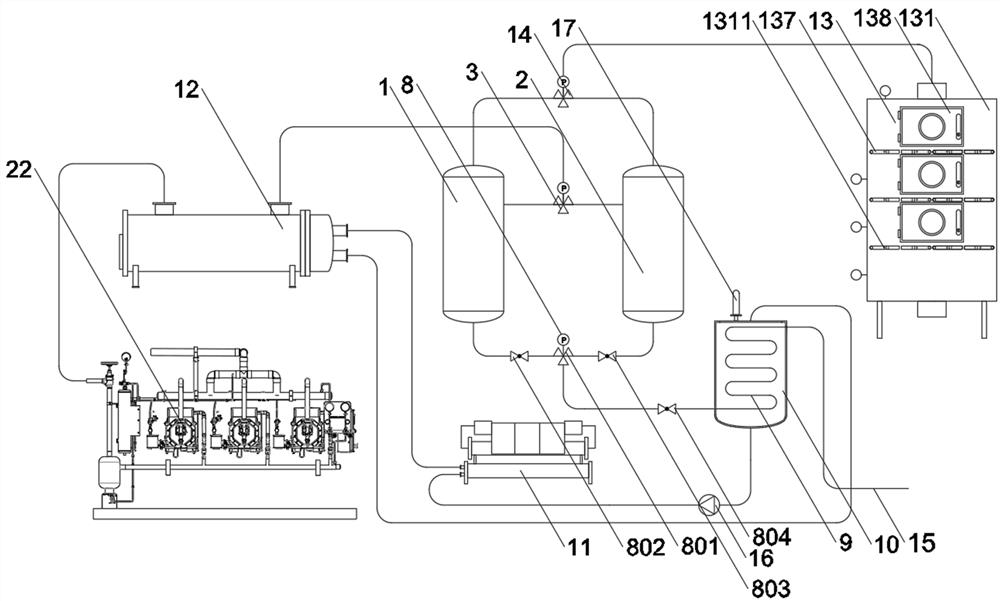

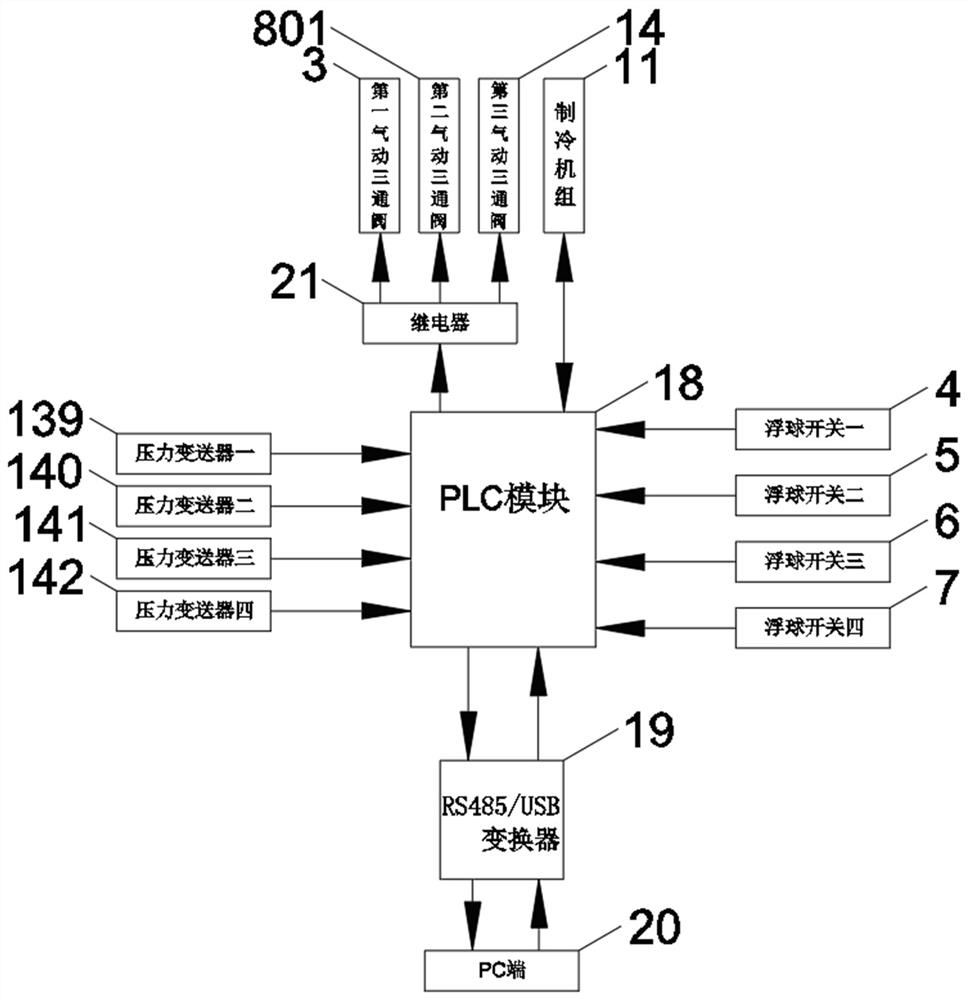

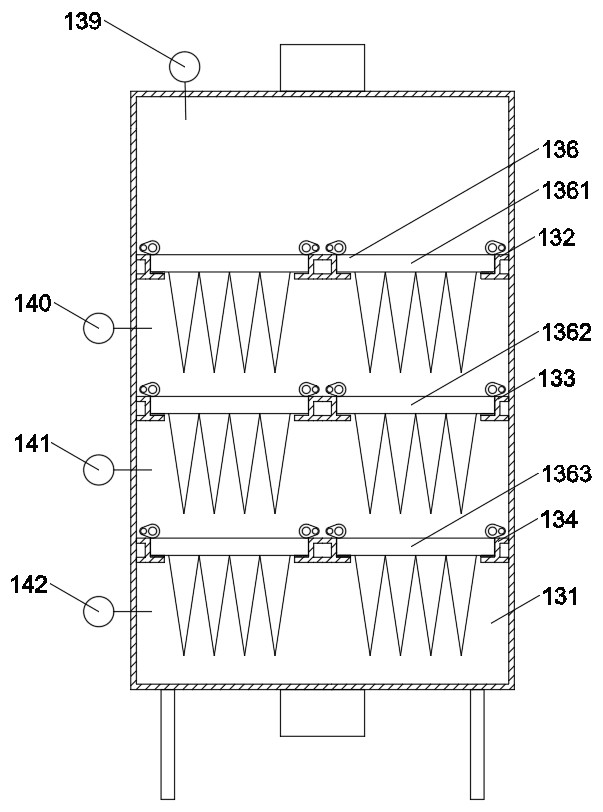

[0022] see Figure 1-Figure 5 , the present invention provides the following technical solutions: a pretreatment device for a medical molecular sieve oxygen production system, including a first water vapor separator (1) and a second water vapor separator (2), and the first water vapor separator (1) and the second water vapor separator (1) A first pneumatic three-way valve (3) is installed on the connecting pipe between the second steam separator (2) and the shell-and-tube heat exchanger (12), and the first steam separator (1) and the second steam separator ( 2) Float switch 1 (4), float switch 2 (5), float switch 3 (6), float switch 4 (7), the first water vapor separator (1) and A drain valve group (8) is installed on the drain pipeline of the second water vapor separator (2), and one end of the drain pipeline is connected with a serpentine heat exchange tube (9), and the serpentine heat exchange tube (9) is fixedly installed on Inside the cold water storage tank (10), the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com