Remote control system for intelligent steel bar bending and hooping robot

A technology of remote control system and steel bar bending hoop, which is applied in general control system, control/adjustment system, program control, etc., can solve the problems of inability to realize remote operation, large equipment changes, troublesome transformation, etc., and achieve remote automatic operation, Reduce manual output and reduce the effect of monitoring operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing:

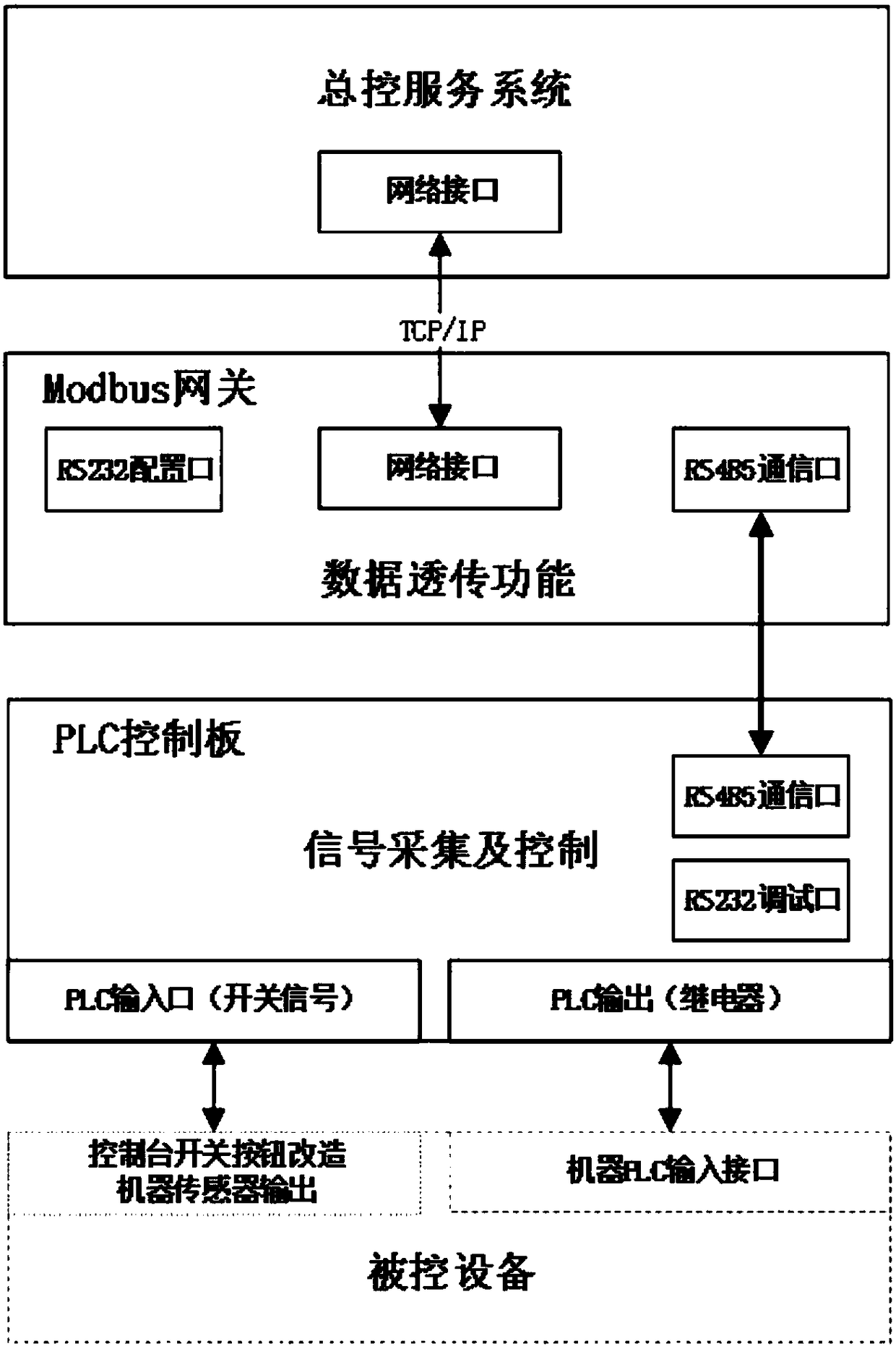

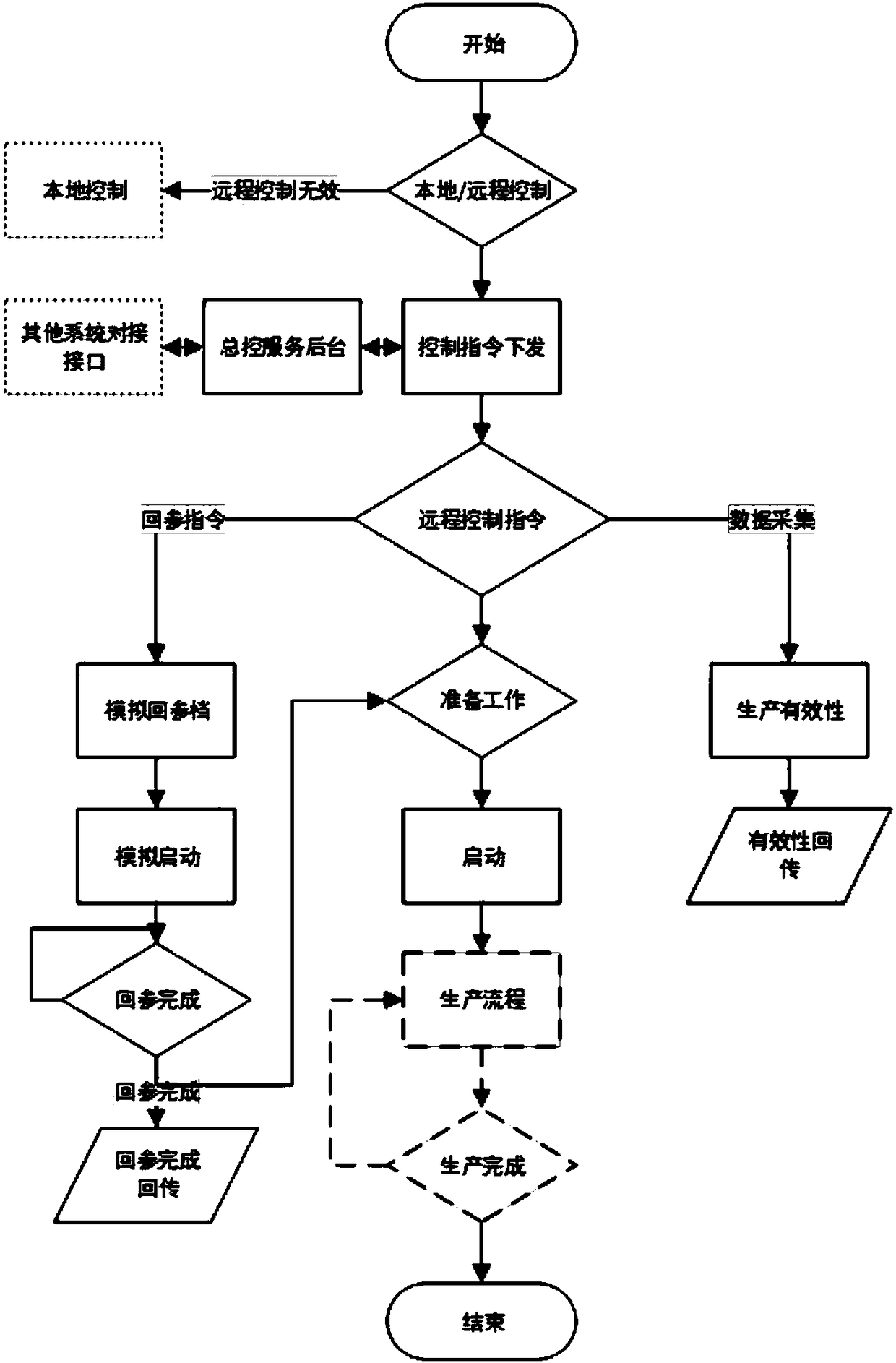

[0019] Such as figure 1 As shown, in order to realize the remote control function of the steel bar hoop bending robot, the control system of the present invention includes a PLC control board, a Modbus gateway and a general control service system, and the PLC control board is connected in series between the equipment console and the original equipment PLC control board Between (the equipment referred to here refers to the steel bar hoop robot), the connection between the input terminal of the PLC control board and the button of the equipment console is first connected, and the output terminal of the PLC control board is connected to the input terminal of the PLC control board of the source equipment. The PLC control board is used to collect the bending shaft in-position switch signal, the production effectiveness signal, the collection of equipment running status and remote co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com