Double-movable-ring-beam continuous lifting mechanism and ascending and descending working method thereof

A lifting mechanism and working method technology, applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of slow lifting speed and low efficiency of self-elevating platforms, and achieve fast lifting speed, reliable operation, easy use and maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

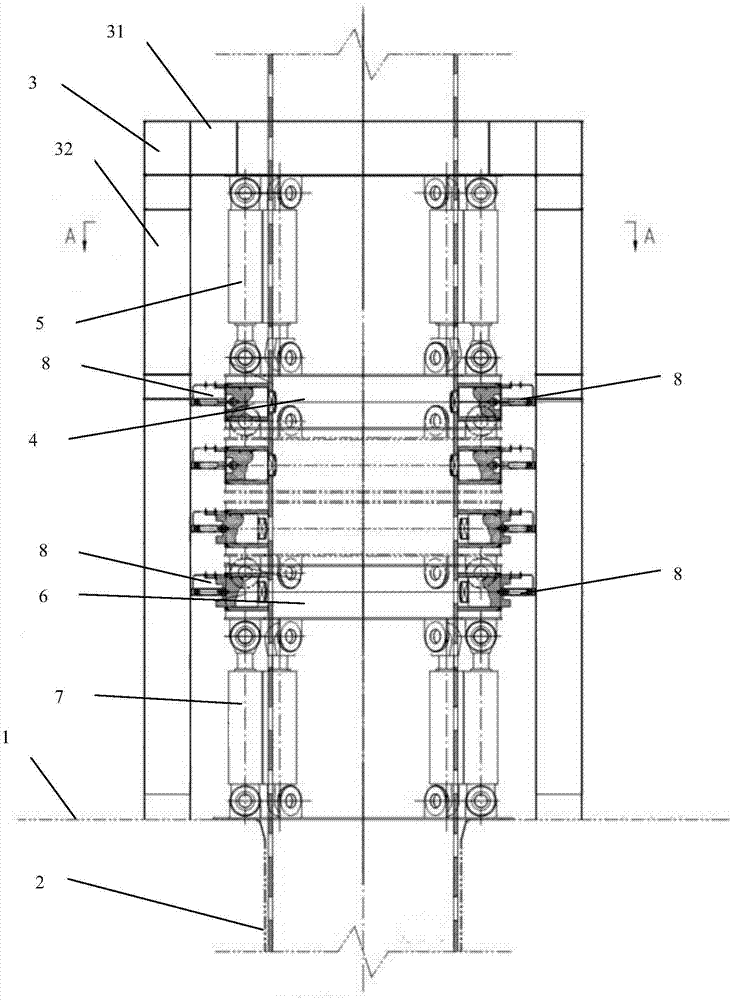

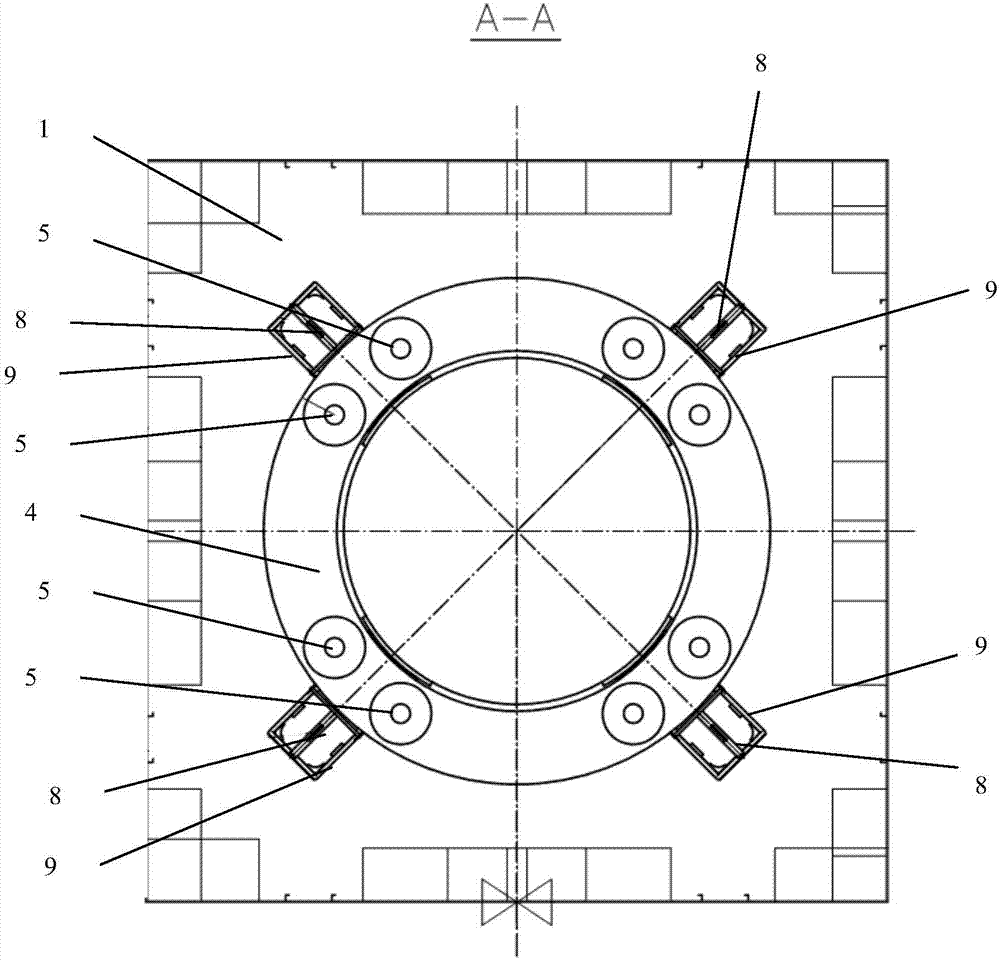

[0043] In further embodiments of the present invention, please continue to refer to figure 1 , figure 2 As shown, both the upper moving ring beam 4 and the lower moving ring beam 6 are box-shaped structures with circular cross-sections or box-shaped structures with polygonal cross-sections.

[0044] In a further embodiment of the present invention, the number of the upper lifting cylinder 5 and the lower lifting cylinder 7 is four, eight or twelve.

[0045] In further embodiments of the present invention, please continue to refer to figure 2 As shown, a bolt bracket 9 is included, and the bolt bracket 9 is a rectangular frame, and the bolt bracket 9 is fixedly connected with the upper moving ring beam 4 or the lower moving ring beam 6 , and a bolt 8 is arranged inside the bolt bracket 9 .

[0046] In a further embodiment of the present invention, several bolt brackets 9 are included, and several bolt brackets 9 form a circular array around the upper moving ring beam 4 or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com