Sealing connecting mechanism

A connection mechanism, sealing and fixing technology, applied in the direction of pipeline connection arrangement, mechanical equipment, pipe/pipe joint/pipe fittings, etc., can solve the problems of large rotational friction, laborious operation, complex structure, etc., achieving low cost, fast and convenient installation , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

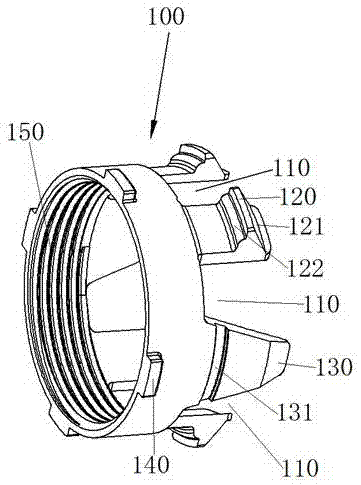

[0033] The technical solutions of the present invention will be further illustrated and described below through specific embodiments in conjunction with the accompanying drawings.

[0034] The sealing connection mechanism of the present invention is used to seal and fix the pipe fittings on the wall hole. Different from the material of pipe fittings, it is not easy to form a more precise connection structure in the wall hole, such as the ceramic opening in the toilet tank for fixing the water inlet valve or the drain valve, or the partition wall of the toilet jet water pipeline or the brush ring water pipeline Ceramic openings, etc., but not limited thereto. Therefore, through the sealed connection mechanism of the present invention, fluid can be introduced or drawn into another pipeline through the pipe fitting.

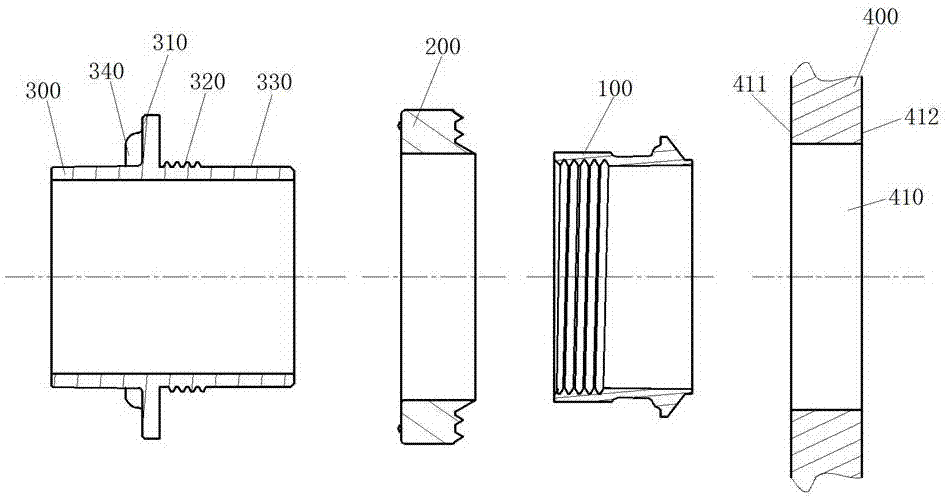

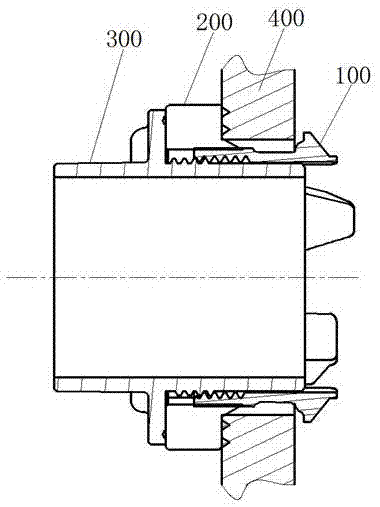

[0035] like Figure 1-5 As shown, the sealing connection mechanism is used to seal and fix the pipe fitting 300 on the solid object or the wall hole 410 of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com