High-position tower packing structure

A high-level tower and packing area technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc. Affect the distribution of wind speed in the packing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

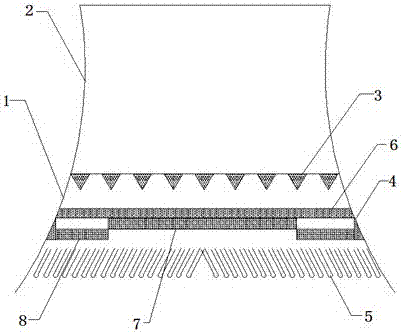

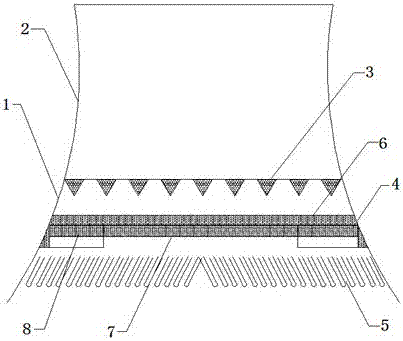

[0032] according to Figure 10 , Figure 11 , Figure 12 It can be seen that the bottom of the cooling tower is provided with a water distribution area 3, a packing area 4 and a water collection area 5 from top to bottom. In the water collection area 16, an air flow channel 12 is provided between two adjacent water collection units, and a plurality of connected annular water collection units are arranged in the annular water collection area 17, and the annular water collection area 17 is inclined inwardly from the tower tube 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com