Method for monitoring bending moment of airplane wing in real time based on FBG (fiber bragg grating)

A fiber grating and real-time monitoring technology, which is applied in force/torque/work measuring instruments, measuring devices, optical devices, etc., can solve the problems of inability to calibrate aircraft in service, inability to realize long-term, real-time online monitoring of aircraft, and cumbersome calibration process, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] A kind of real-time monitoring method of aircraft wing bending moment based on fiber grating provided by the present invention, see Figure 4 As shown, it is realized through the following steps:

[0067] Step 1: Paste the fiber grating sensor on the wing of the aircraft.

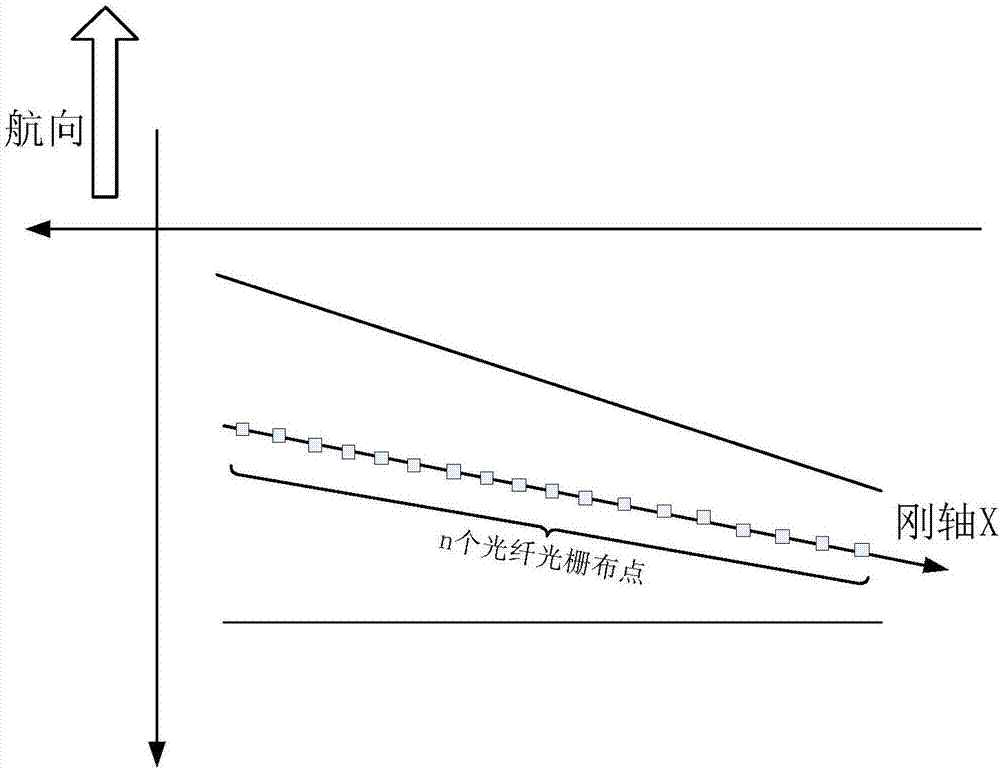

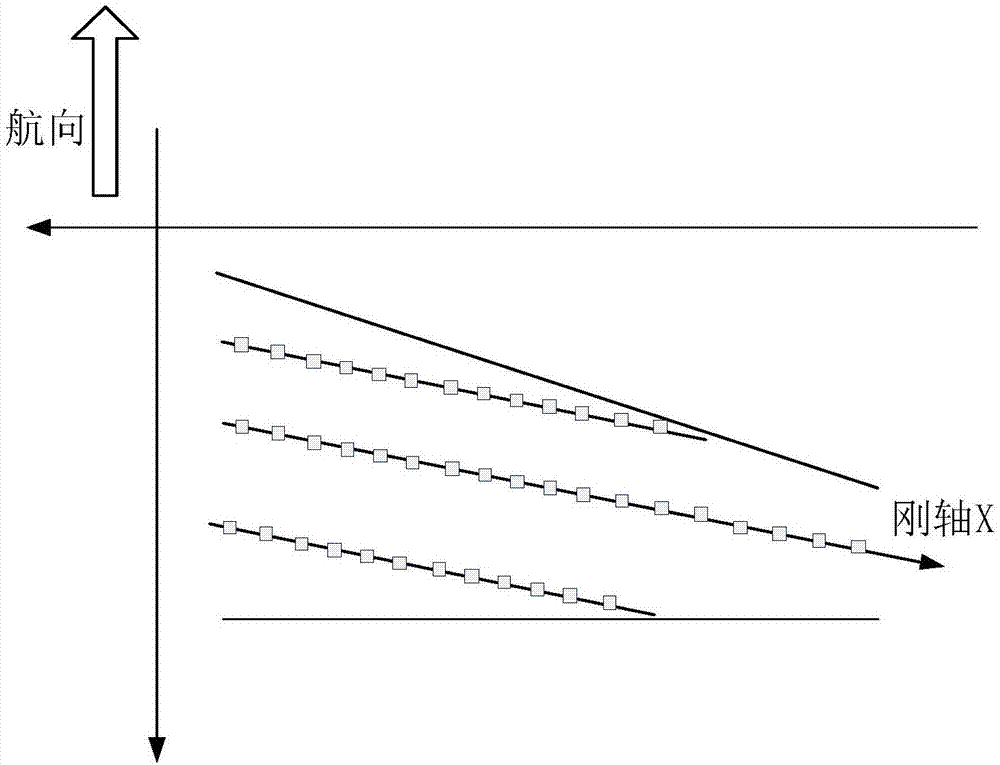

[0068] First of all, it is necessary to determine the position of the rigid axis of the aircraft wing to be measured, and establish the X coordinate along the direction of the rigid axis. The root of the wing is the starting coordinate 0, and the direction extending to the end of the wing is the positive direction;

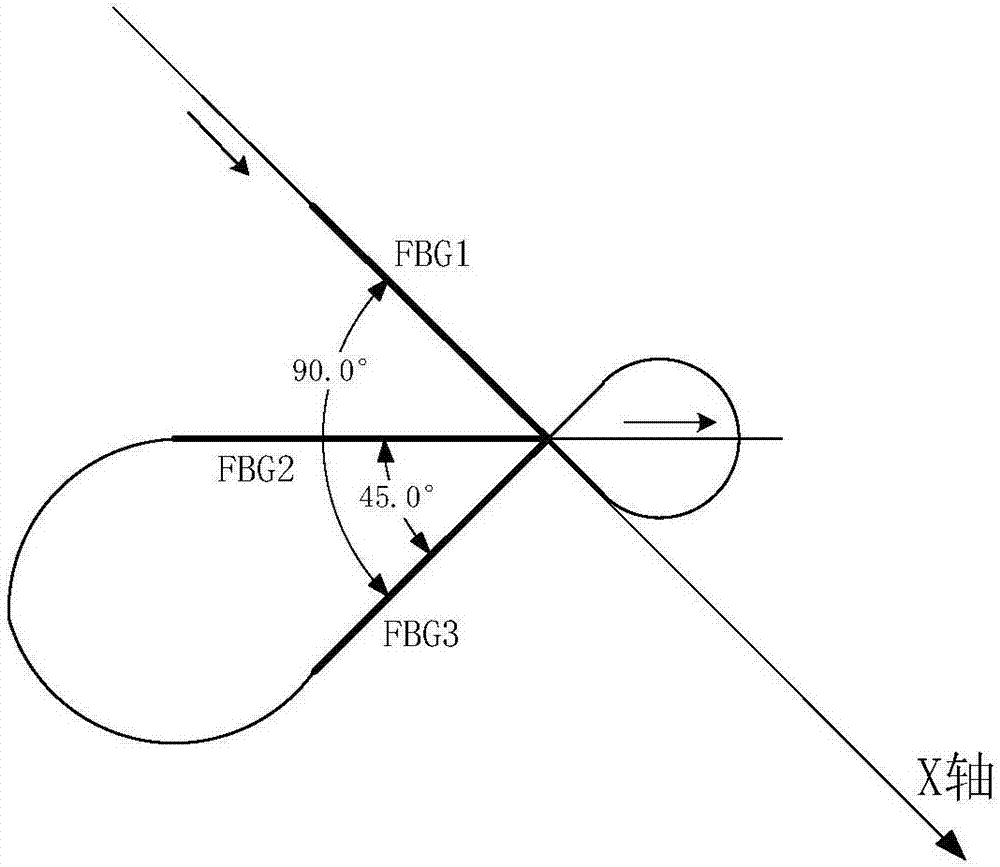

[0069] Secondly, on the surface of the wing corresponding to the rigid axis, a fiber grating sensor group is placed along the direction of the rigid axis of the wing. Each group of fiber grating sensors is a right-angle rosette composed of three fiber gratings with different wavelengths, as shown in figure 1 As shown, the direction of the fiber grating sensor 1, that is, FBG1, is the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com