Portable protective airtight door air-tightness detection device

A detection device, portable technology, applied in the field of sealing performance detection devices, to achieve the effect of improving efficiency, saving operators and auxiliary materials, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

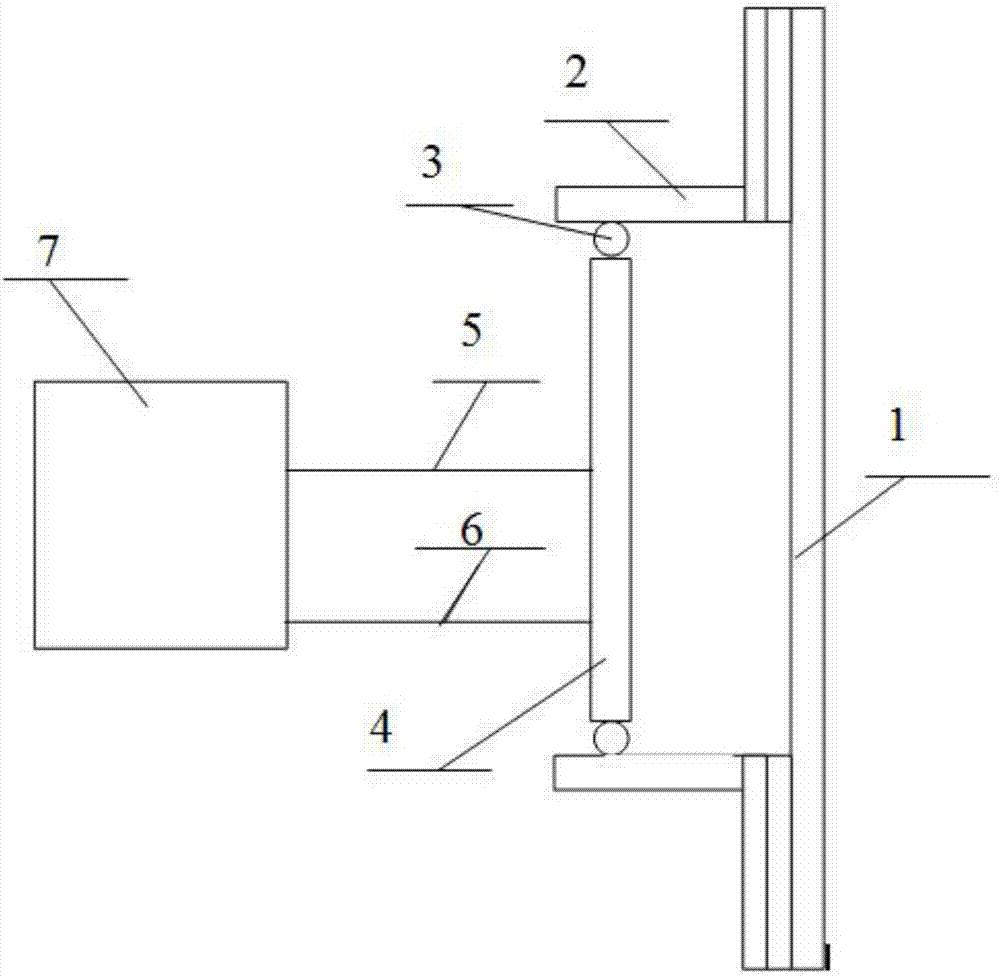

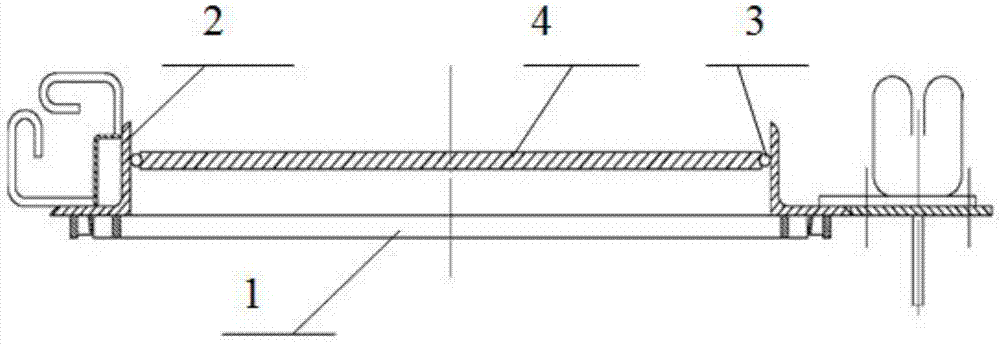

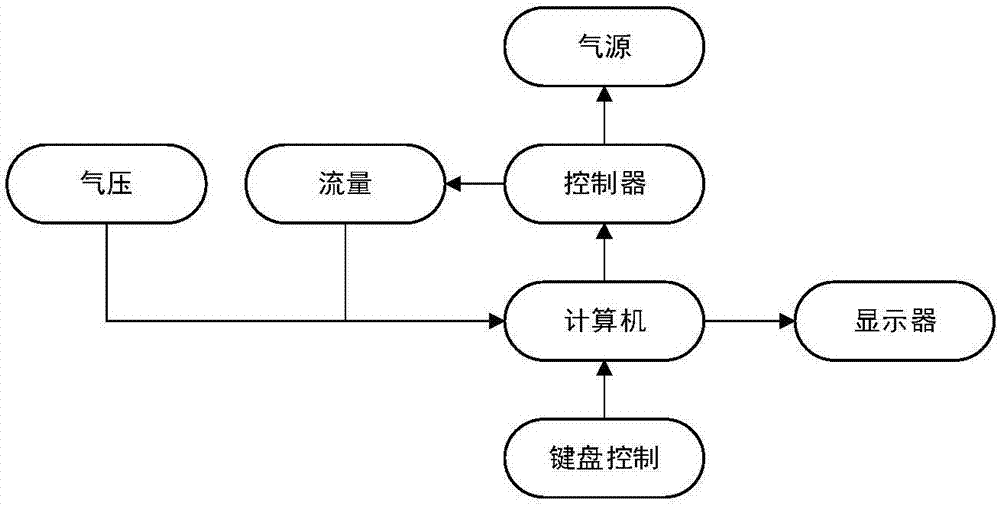

[0031] Such as Figure 1-2 As shown, the portable protective airtight door airtight performance detection device includes an air source, a pressure measuring device, a portable console 7, a sealed support plate 4, a sealed pipe 3, a civil air defense door 1, and civil air defense door frames 2 on both sides of the civil air defense door 1. Portable The console 7 controls the air source to inject gas into the sealed tube 3 through the intake pipe 5 connected to the sealed tube 3, and the sealed tube 3 expands to both sides, and is tightly pressed against the civil air defense door frame 2 and the sealed support plate 4 to form an overpressure chamber. During the detection, the overpressure chamber and the portable console 7 are connected into a system and installed by using the air inlet pipe and the pressure measuring pipe, so as to realize the airtight performance detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com