Semiconductor gas sensor test system

A technology of gas sensor and test system, which is applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of long desorption time of sample gas and unsuitable for gas testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

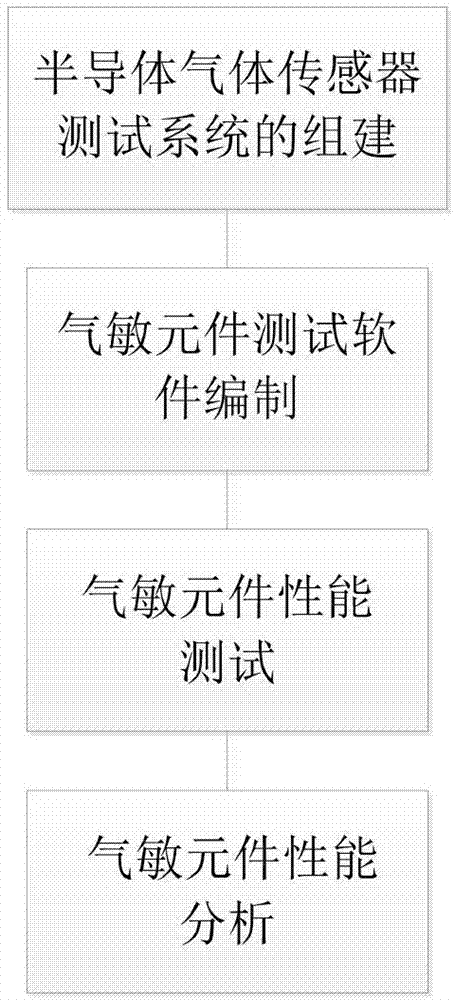

[0043] A test method for a semiconductor gas sensor, characterized in that it comprises: the steps of building and testing a semiconductor gas sensor test system, and the step of analyzing the performance of the semiconductor gas sensor test system and the semiconductor gas sensor.

Embodiment 2

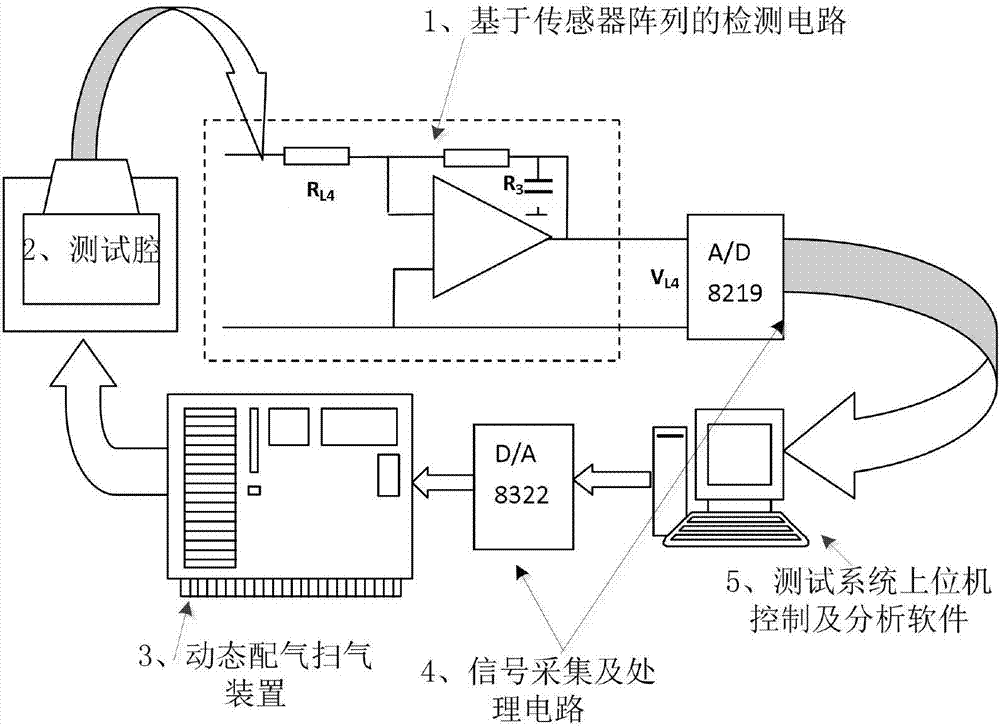

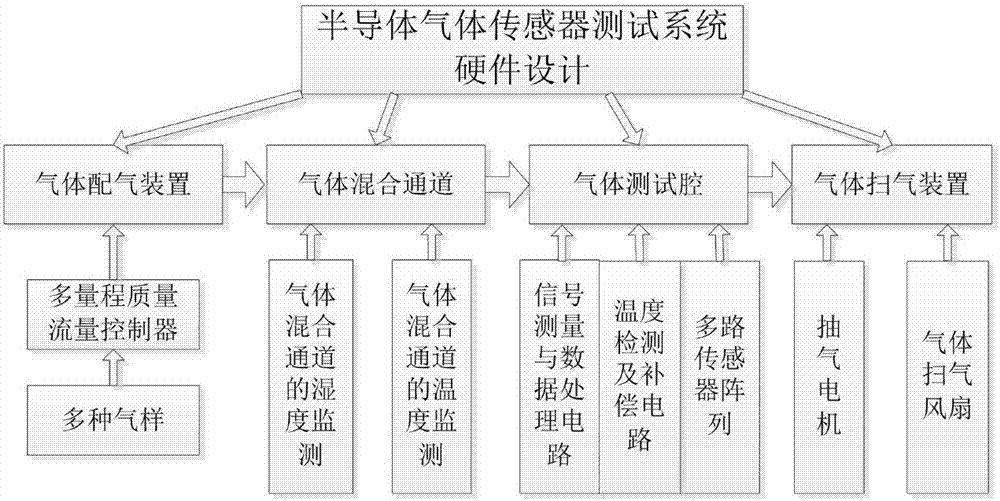

[0045] It has the same technical solution as that of Embodiment 1, and more specifically: in the steps of setting up and testing the semiconductor gas sensor test system, the semiconductor gas sensor test system is used to dynamically distribute and control different gases at a given concentration. Make the multi-sensor array monitor the change of the surface conductivity of the gas sensor in real time when the gas is introduced;

[0046] The semiconductor gas sensor testing system includes: a sampling device for automatically performing sample gas concentration ratios, a gas sensor heating and temperature measuring device, used to coordinate actions with the sampling device, and automatically collect 4 to 4 gas samples in different gas sample environments. The signal measurement and data acquisition circuit for the measurement signal of the 6-way gas sensor, the data processing circuit for data processing the collected measurement signal; and the temperature compensation circu...

Embodiment 3

[0056] It has the same technical solution as Embodiment 1 or 2, more specifically: the software part of the gas sensor testing system includes a gas circuit control module, a voltage sampling module, a temperature compensation module, a data processing module and a display function module, wherein :

[0057] The gas circuit control module sets the control parameters, and the parameters include the time before ventilation, the ventilation time, the time after gas stop, the data sampling time interval, the type of mixed gas, the concentration of various gases and the control voltage of the carrier gas. Set to control the output of multiple gas samples to achieve gas distribution. During the gas distribution process, the gas flow rate and the working temperature of the components remain unchanged throughout the test process;

[0058] The voltage sampling module controls the start of voltage sampling, sampling interruption and sampling end;

[0059] The data processing module per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com