Magnetic element

A technology of magnetic components and isolation components, applied in electrical components, magnetic cores/yokes, inductors with magnetic cores, etc., can solve the problems of increased energy consumption, limited efficiency improvement, high magnetic flux leakage, etc., to reduce magnetic flux leakage and magnetic loss, improving the utilization rate of windings, and increasing the number of windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

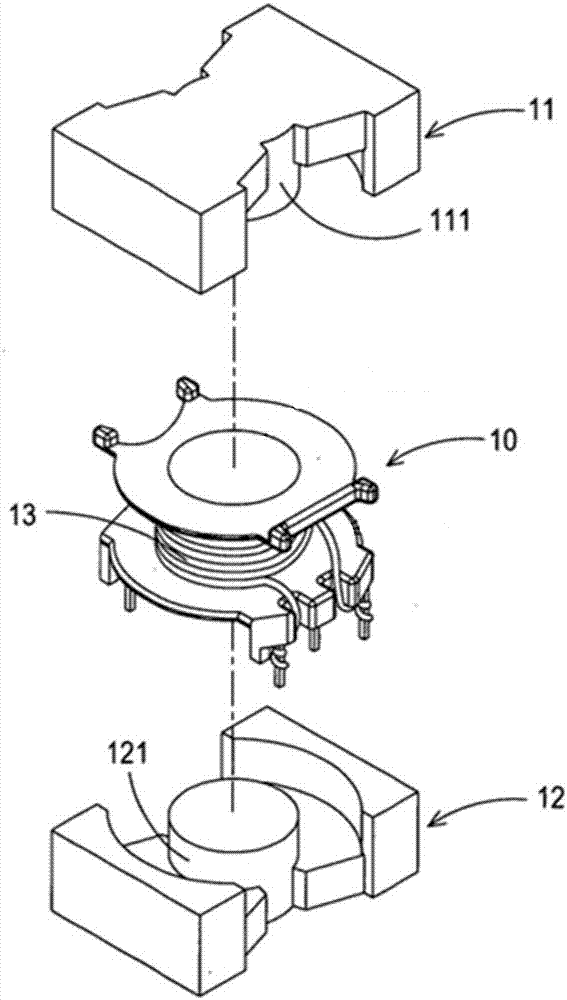

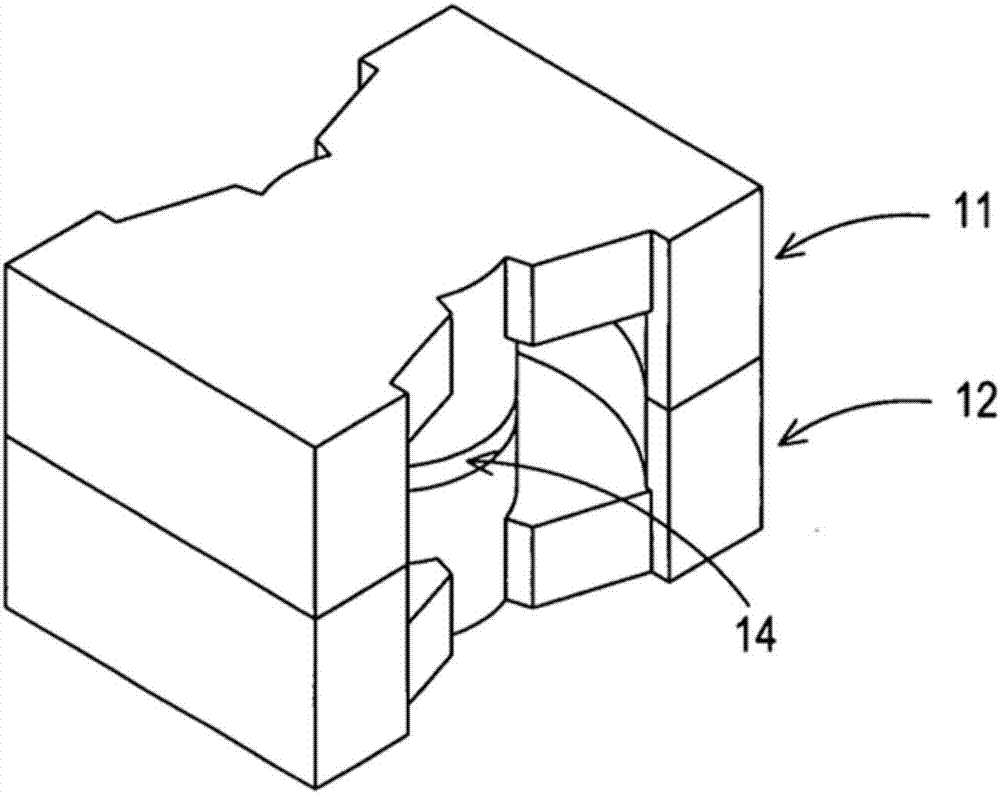

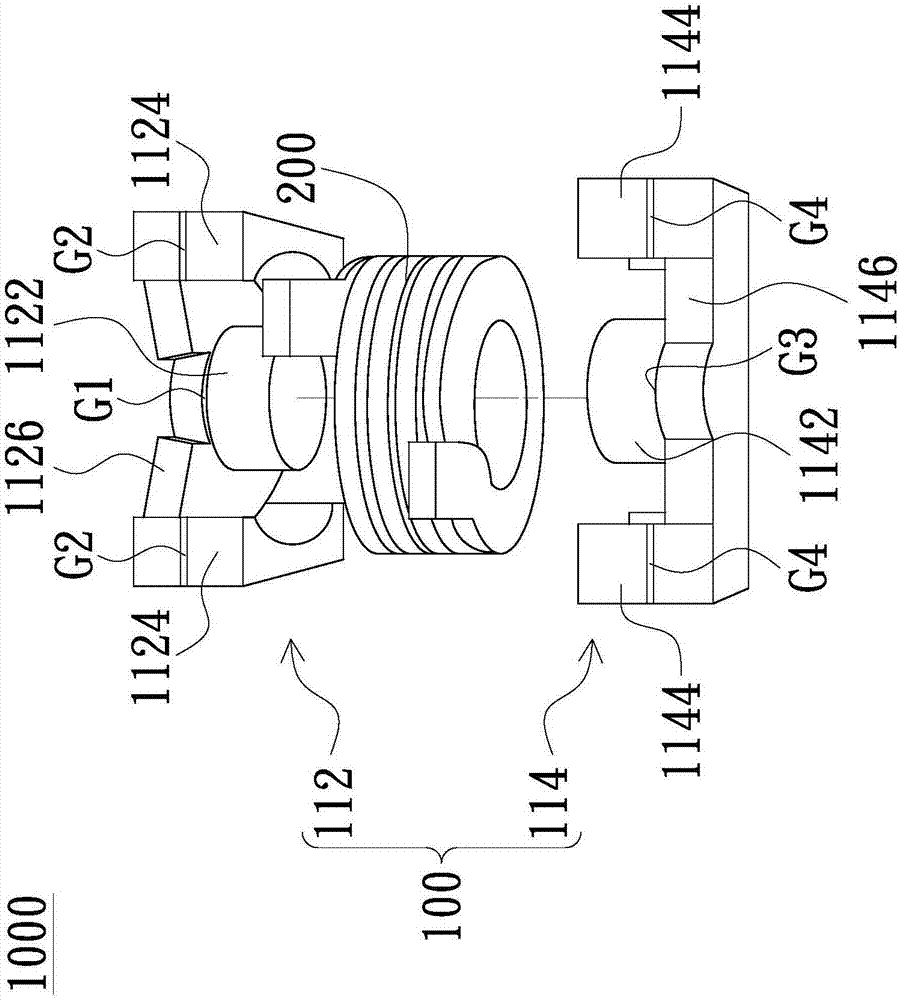

[0076] see Figure 2A , 2B and 3A, which represent an embodiment of the magnetic element of the present invention. The magnetic element 1000 of the present invention includes a magnetic core 100 and a winding set 200 . Such as Figure 3A As shown, the magnetic core 100 has a central column 110, two side columns 120 and a winding space 130, as Figure 2B As shown, the winding group 200 is arranged in the winding space 130 and wound around the central column 110, wherein the central column 110 forms two central column air gaps G1, G3 and each side column 120 forms two side columns respectively The air gaps G2 and G4, and the magnetic core piece 100 are made of magnetically permeable material.

[0077] Such as Figure 2A As shown, in this embodiment, the magnetic core member 100 includes a first magnetic core 112 and a second magnetic core 114 that are butted with each other, the first magnetic core 112 has a first central column 1122 and two first side columns 1124, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com