Universal spiral compaction type grounding wire operating rod

A technology of screw compression and operating rod, which is applied in the direction of wire winding connector, clip connection conductor connection, etc., can solve the problems of increasing manufacturing and purchasing costs, increasing difficulty of high-lift operation, increasing the weight of wire clamps, etc., and reducing installation time, increasing electricity sales, and eliminating safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

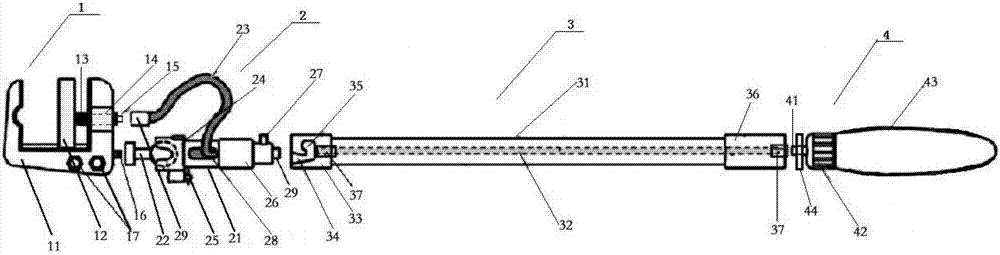

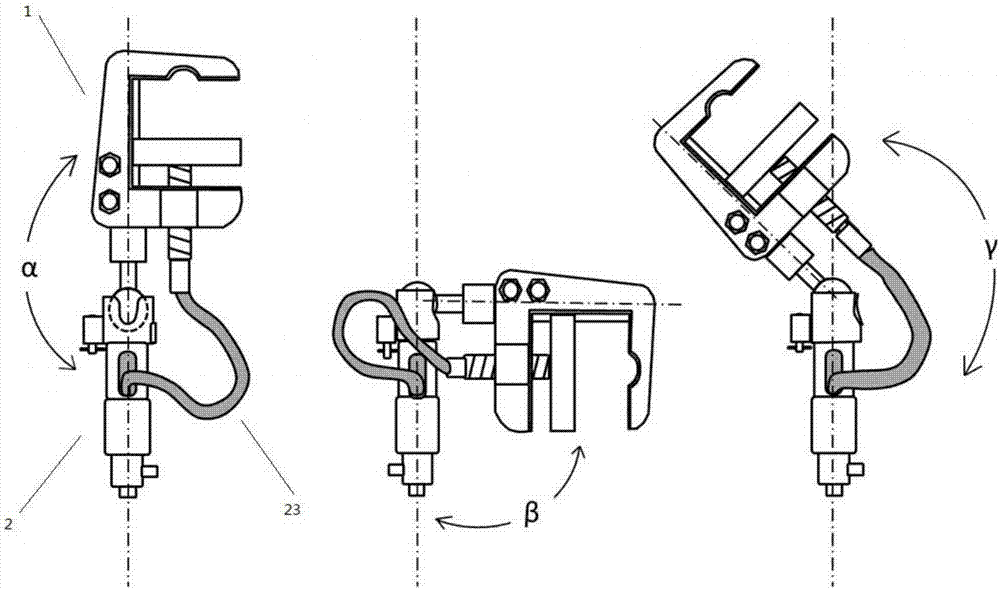

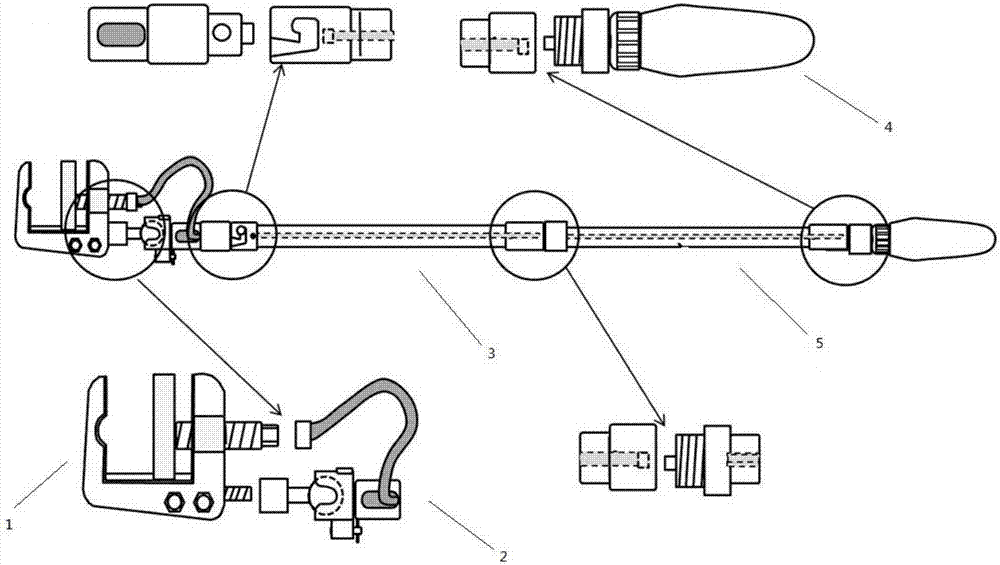

[0022] The present invention will be further described below in conjunction with accompanying drawing.

[0023] Such as figure 1 As shown, a universal screw compression type grounding wire operating lever includes a wire clamp assembly 1, an adjustment assembly 2, an operating rod assembly 3 and a transmission handle assembly 4 connected in sequence. The wire clamp assembly 1 includes a wire clamp 11, The wire clamp 11 is provided with a crimping tongue 12 which is in motion-fit connection with a helical compression bolt 13, and the helical compression bolt 13 rotates in the threaded tube 14 to push the crimping tongue 12 to compress the wire, and the helical compression bolt 13 is provided with a compression bolt clamp 15 connected to the flexible shaft clamp 29, and the wire clamp 11 is provided with a connection between the universal joint screw 16 and the universal joint ball 22 and the connection for connecting the ground soft copper wire Screw 17; the adjustment assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com