Automatic cleaning mop mopping machine

An automatic cleaning and floor mopping technology, which is applied to manual floor scrubbing machines, carpet cleaning, floor cleaning, etc., can solve problems such as troublesome, inability to continuously mop the floor, and untimely removal and cleaning, so as to improve the cleaning effect and save energy. The effect of water is obvious and beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

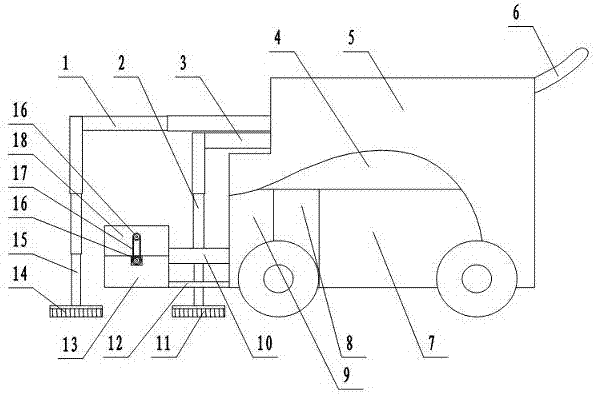

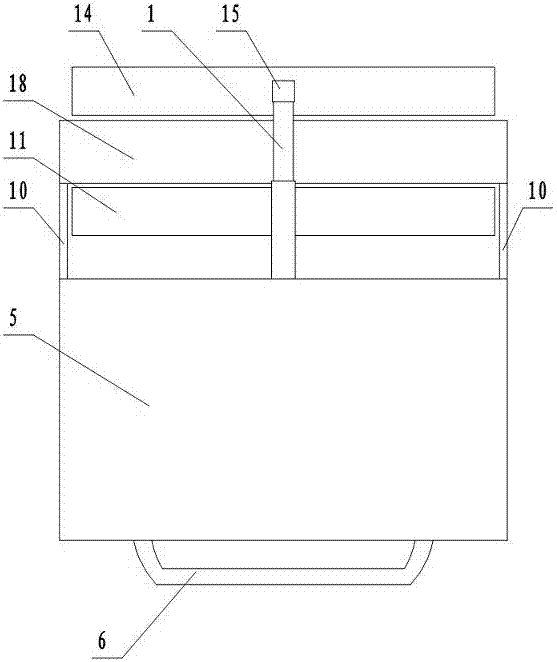

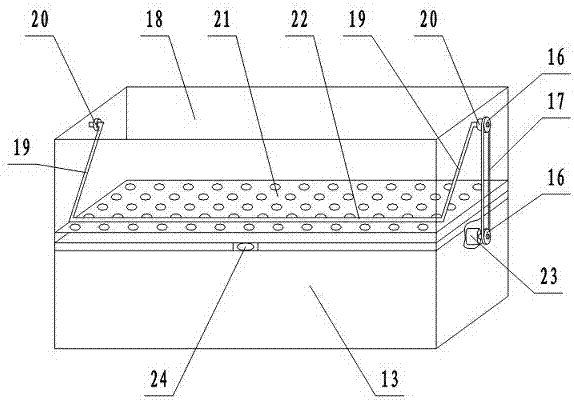

[0021] figure 1 In the middle, it is the overall structure diagram of the split-type mopping model of the automatic cleaning mopping machine. The split-type mopping model of the automatic cleaning mopping machine is hereinafter referred to as the split mopping machine. figure 1 In, is the side view of the split mopping machine. figure 2 in, yes figure 1 top view. combine figure 1 , figure 2 Narrate together. A front arm frame 1 and a rear arm frame 3 are installed on the front top of the vehicle body 5 . The front arm frame 1 is above the rear arm frame 3 . figure 2 Among them, the front arm frame 1 blocks the rear arm frame 3 and cannot be seen. The front end of the forearm is vertically connected with the upper end of the premise bar 15 . The front end of the rear arm frame 3 is vertically connected with the upper end of the rear lifting rod 2 . Premise bar 15 lower ends are connected in the middle of the flat plate above front handkerchief 14. The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com