Built-in pneumatic double-helix flow-guiding automatic fastener rinsing tank

A washing tank and double-helix technology, which is applied in the field of built-in pneumatic double-helix diversion automatic fastener washing tank, can solve the problems of less cleaning volume, lower cleaning efficiency, poor cleaning effect, etc., to ensure safety and continuity , Improve cleaning efficiency, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

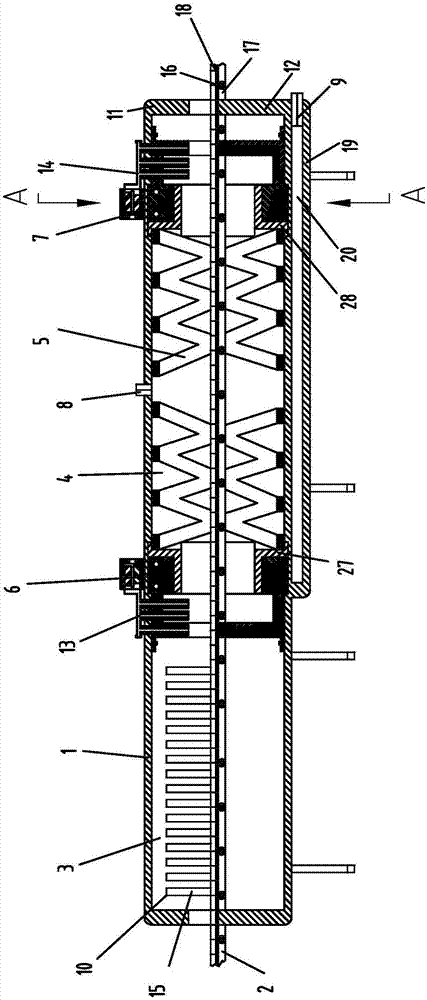

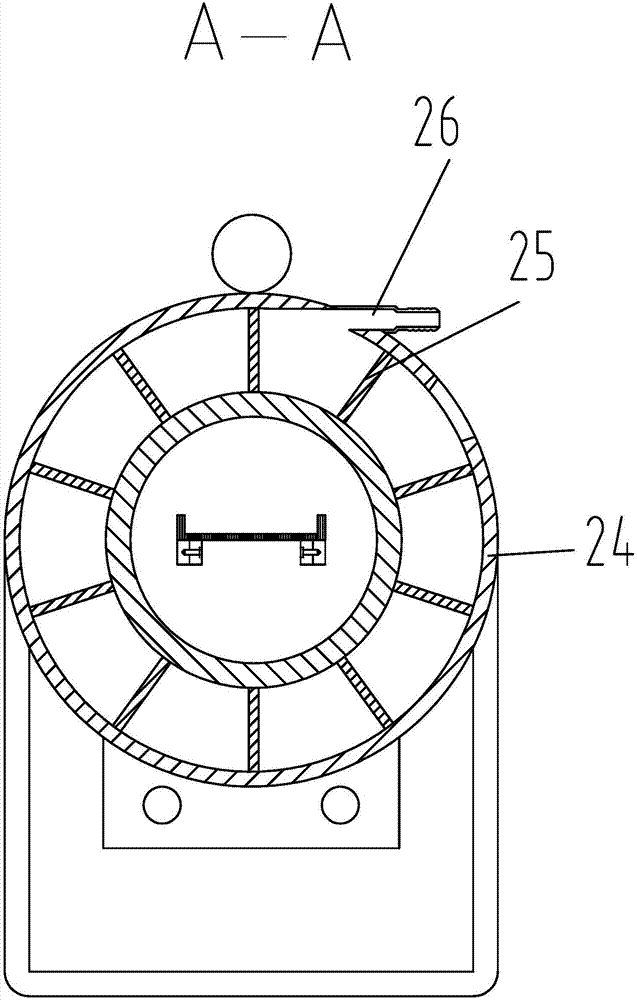

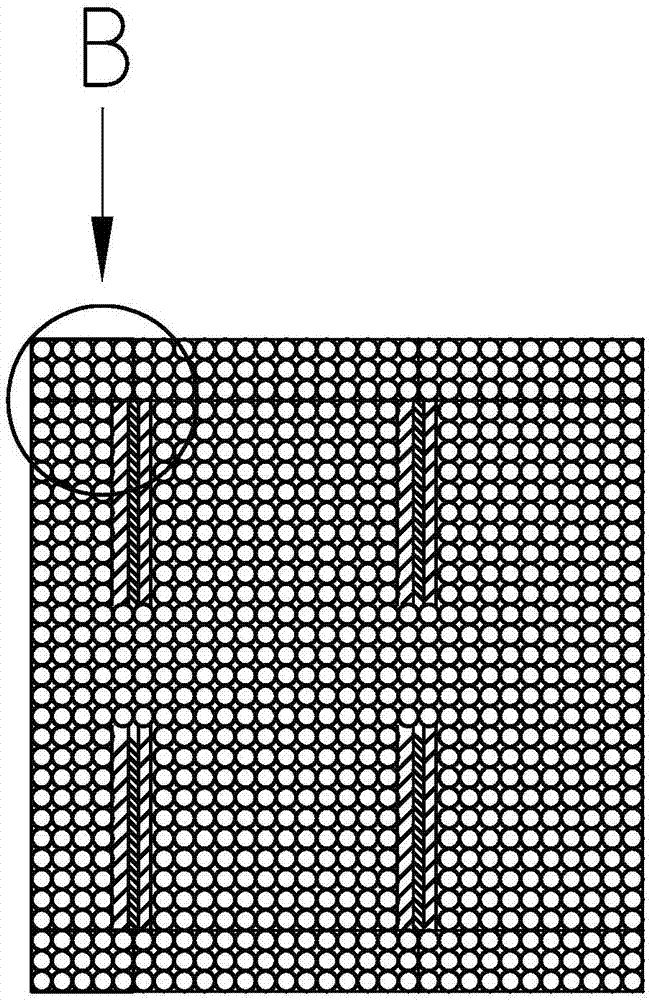

[0022] see figure 1 , the present invention provides a technical solution: including a shell with openings at both ends and a conveyor belt 2 arranged inside the shell, the shell 1 is set as a washing tank 3 and a drying tank 4, and the washing tank 3 is provided with a belt The roller frame 7 of double helical blades, the two openings in the water washing tank are respectively provided with air seal mechanisms, the roller frame and the air seal mechanism are powered by the air compressor in the housing, and the top of the water washing tank 3 is provided with a water inlet , the bottom is provided with a water outlet, the drying tank 4 is provided with a blower device, and an opening for the conveyor belt 2 to pass is opened between the washing tank 3 and the drying tank 4, and the conveyor belt 2 is horizontally arranged to pass through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com