Variable cross-section rotary extrusion mold and using method thereof

A technology of changing section and die, applied in the field of material extrusion, can solve the problems of low forming efficiency and many processes, and achieve the effect of improving forming efficiency, simple equipment and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: The preform is a cylinder with a circular cross-section having a diameter of 10 mm and a length of the cylinder of 45 mm.

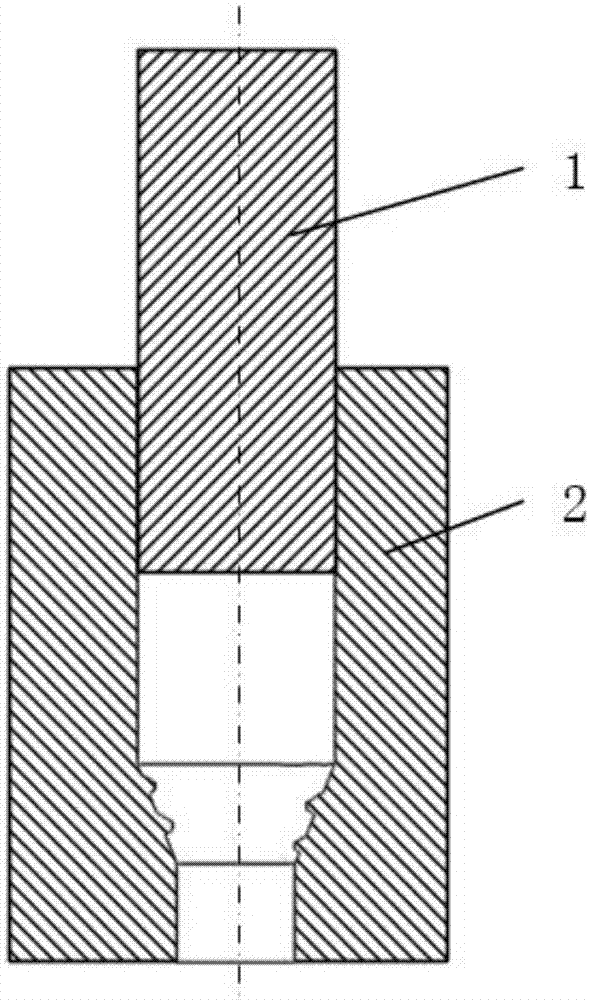

[0023] refer to figure 1 As shown, a rotary extrusion die with variable cross-section includes a punch 1 and a die 2, the diameter of the circular cross section of the punch 1 is 10mm, and the length of the punch 1 is 75mm.

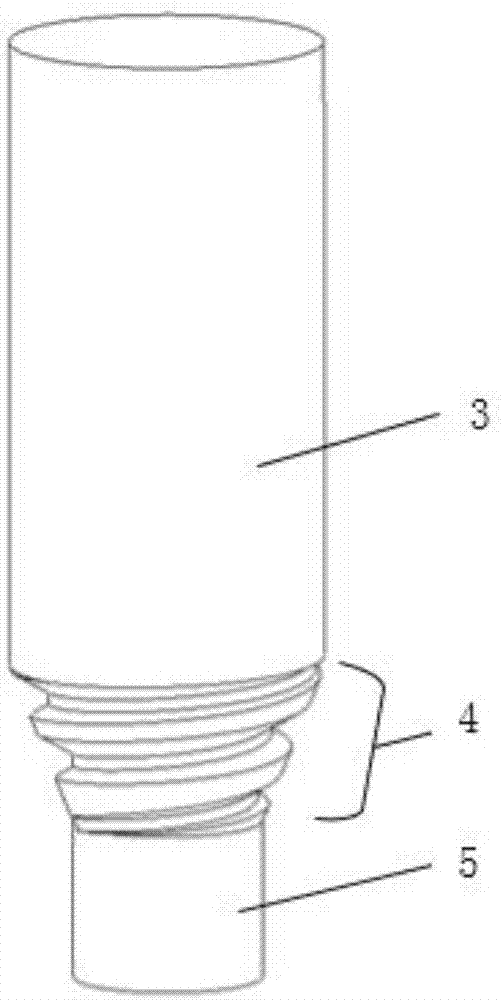

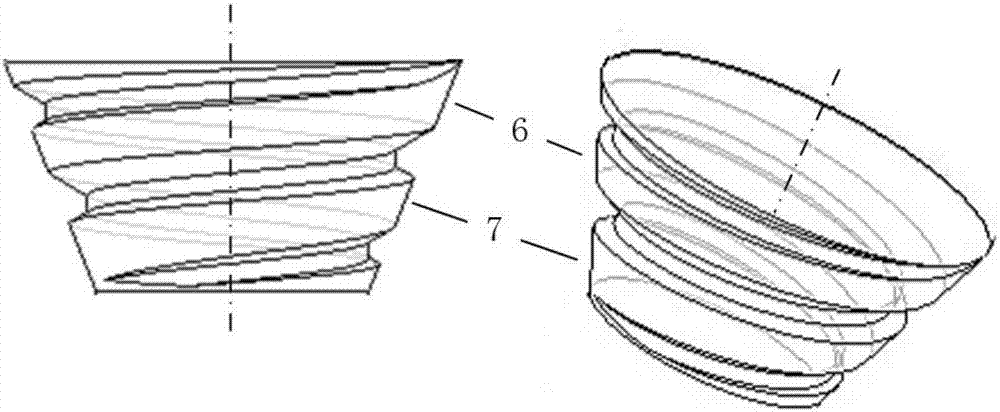

[0024] refer to figure 2 As shown, a molding cavity is provided in the die 2; the molding cavity includes an introduction section 3, the diameter of the cross section of the introduction section 3 is 10 mm, and the length of the introduction section 3 is 60 mm; the lower end of the introduction section 3 is connected to a multi-stage The upper end of the threaded section 4 of the rotary extrusion section, the lower end of the threaded section 4 of the multistage rotary extrusion section is connected to the lead-out section 5, the upper end surface of the threaded section 4 of the multistage rotary extrusion section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com