Steel material for forged steel brake disc of high-speed train with speed of 350 km and above per hour and forging process of steel material

A brake disc and speed-per-hour technology, which is applied in the field of alloy forged steel, can solve the problems affecting the use effect and life of the brake disc, and the unstable quality of cast steel production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific implementation.

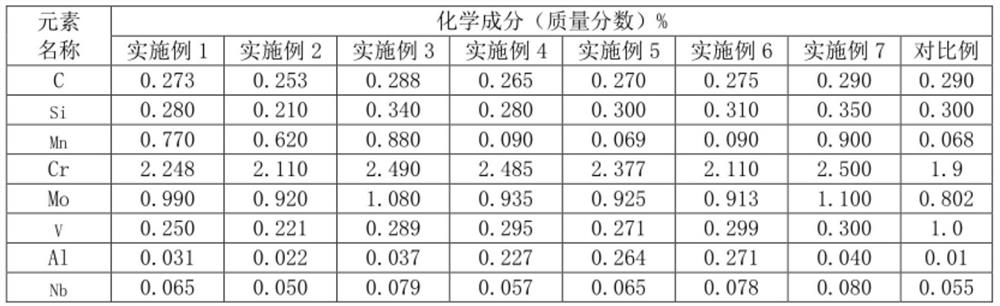

[0033] 350km per hour of the present invention and above high-speed rail brake disc forging steel material each component and its mass percent scope are as follows: C: 0.25-0.29%; Si: 0.2-0.35%; Mn: 0.6-0.9%; Cr: 2.1- 2.5%; Mo: 0.9-1.1%; V: 0.2-0.3%; Al: 0.02-0.04%; Nb: 0.05-0.08%; the balance is iron and other elements, and other elements are residual trace elements.

[0034] Residual trace elements include Ti, Co, Cu, As, N, H, O, P, S, among which the mass percentage of Ti is less than or equal to 0.02%; the mass percentage of Co is less than or equal to 0.20%; the mass percentage of Cu is less than or equal to 0.20%; the mass percentage of As Less than or equal to 0.02%; N mass percentage is less than or equal to 90×10 -6 %; H mass percentage is less than or equal to 1.5×10 -6 %; O mass percentage is less than or equal to 18 × 10 -6 %; P mass percentage is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com