Color press horizontal-printing high-difference deviation rectification device

A technology of deviation correction device and color printing machine, applied in printing device, printing, etc., can solve problems such as poor flatness of printing media that are difficult to deal with, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] With reference to the accompanying drawings, the present invention will be described as follows.

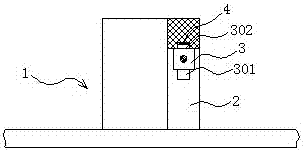

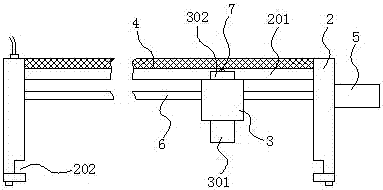

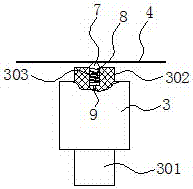

[0018] Such as Figure 1-5 As shown, the horizontal printing height difference correction device of the color printer includes a color printer body 1 and a correction device. The correction device controls the distance between the nozzles in the color printer body 1 and the surface to be printed. The correction device is located at the input end of the printing medium of the color printer body 1. The correction device includes a gantry bracket 2, a displacement sensor 3, a screw 6, and a motor 5. The gantry bracket 2 is relatively fixed to the head 101 of the color printer body 1, and the upper part of the gantry bracket 2 The bottom of the beam is provided with a horizontal slideway 201, and two conductive strips 4 are provided in the slideway 201 along the length direction of the slideway 201, and the two conductive strips 4 are electrically connected to the main controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com