An integrated CNC engraving machine tool

A technology of CNC engraving machine and machine tool, which is applied in the directions of engraving, chemical instruments and methods, cleaning methods and utensils, etc. It can solve the problems of increased input cost, low work efficiency, and single function of LED lights, etc., and achieves improved processing speed and reduced The effect of the action steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

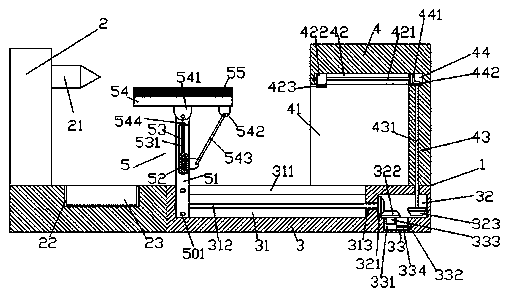

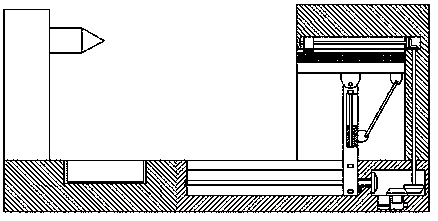

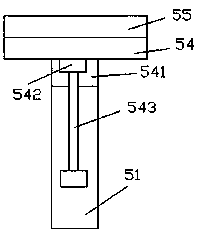

[0019] Such as figure 1 with image 3 As shown, a kind of integrated numerical control engraving machine tool of the present invention comprises frame 3, and the upper left side of described frame 3 is provided with the numerical control engraving machine 2 that can slide according to track on described frame 3, and described numerical control engraving A steerable engraving drill 21 is provided on the upper right side of the machine 2, a dust removal part 4 is provided on the upper right side of the frame 3, and a dust removal part 4 is provided on the frame 3 between the CNC engraving machine 2 and the dust removal part 4 There is a workpiece part 5, the inside of the right side of the frame 3 between the workpiece part 5 and the dust removal part 4 is provided with a first sliding groove 31, and the top of the first sliding groove 31 is provided with a The connecting groove 311 extended from the sliding groove 31, the first driving chamber 32 is provided in the frame 3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com