Weaving machine rubber sheet winding device

A winding device and rubber technology, which is applied in the field of textile printing and dyeing, can solve the problems of inability to guarantee the consistency of elongation, the quality of gray cloth, and secondary rework, etc., and achieve the effects of reducing labor intensity, improving driving efficiency, and reducing replacement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

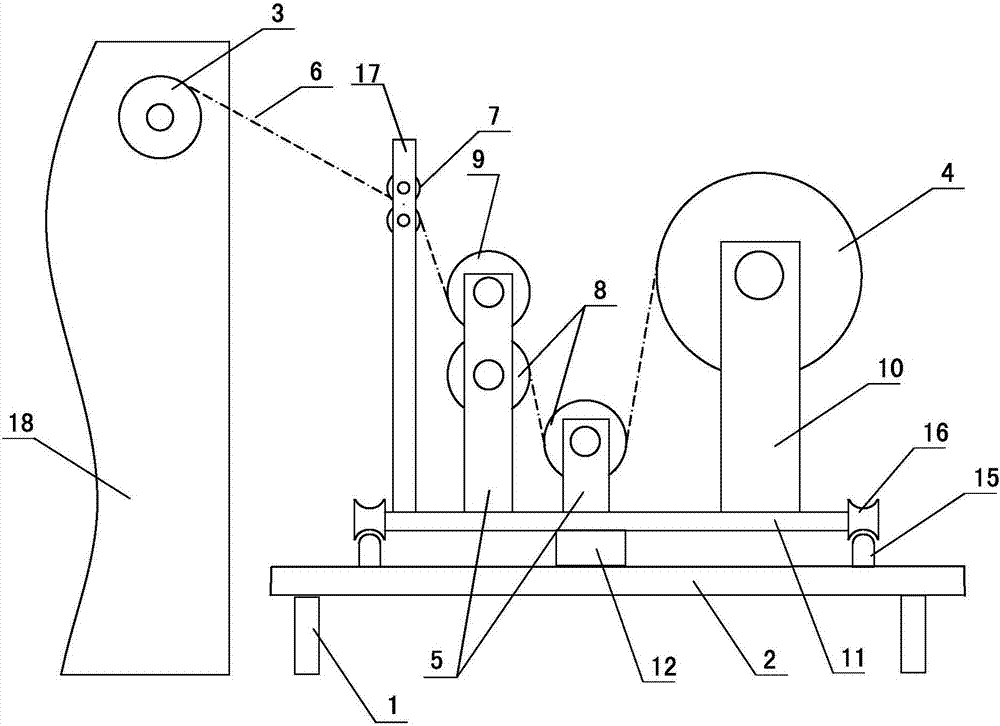

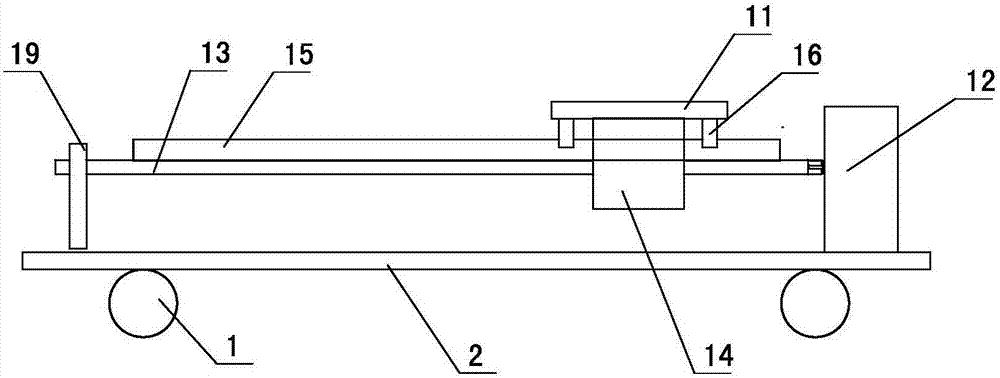

[0010] The invention will be further described below in conjunction with the accompanying drawings. exist Figure 1-2 In the example shown: the bottom of the flatbed cart 2 is provided with rollers 1, two parallel guide rails 15 are provided on both sides of the upper end surface of the flatbed cart 2, and two groups of guide wheels 16 are provided at the bottom of the horizontal pallet 11, and the guide wheels 16 are arranged on the guide rails 15. upper sliding; the motor 12 is fixed on the flat car 2, and one end of the screw mandrel 13 is fixedly connected with the output end of the motor 12, and the other end of the screw mandrel 13 is fixed on the flat car 2 through the support block 19, and the wire sleeve 14 is installed on the screw mandrel 13, The upper end surface of the wire sleeve 14 is fixedly connected with the bottom surface of the horizontal supporting plate 11; And the tension roller 9 are respectively installed on the horizontal supporting plate 11 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com