Short-process processing method of polyester spandex and tencel knitted color strip fabric

A processing method, the technology of polyester spandex, is applied in the processing of textile materials, knitting, weft knitting, etc., which can solve the problems of cumbersome and lengthy technological process, poor soaping fastness, etc., and reduce costs, reduce wrinkles and curling, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

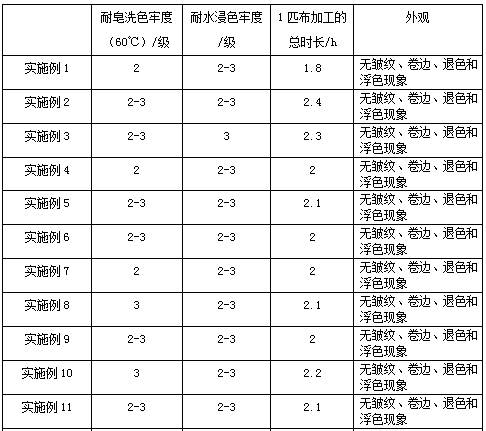

Embodiment 1

[0035] Embodiment 1: a kind of processing method of short process polyester spandex, tencel knitted color strip fabric, is made up of following steps:

[0036] The short-process polyester spandex and tencel knitted color striped fabric provided in this embodiment is a colored striped fabric obtained by knitting polyester spandex fibers and tencel fibers through a knitting method as a rough cloth.

[0037] The disperse dye that the colored stripe fabric of this implementation adopts is disperse blue 291.

[0038] 1) Open-width water washing process: After unwinding the above-mentioned rough cloth, open-width water washing is carried out at a temperature of 60°C and a vehicle speed of 25 m / min.

[0039] 2) Pre-setting process: 1) The rough cloth after the open-width washing operation is passed through a knitted fabric setting machine (Wuxi Xindu Printing and Dyeing Machinery Co., Ltd.), at 180°C, with an overfeed of 25%, and a speed of 25 m / min. Perform the setting operation be...

Embodiment 2

[0042] Embodiment 2: a kind of processing method of polyester spandex, tencel knitted color strip fabric of short process, is made up of following steps:

[0043] The short-process polyester spandex and tencel knitted color striped fabric provided in this embodiment is a colored striped fabric obtained by knitting polyester spandex fibers and tencel fibers through a knitting method as a rough cloth.

[0044] The disperse dye that the colored stripe fabric of this implementation adopts is disperse yellow 163.

[0045] 1) Open-width water washing process: After unwinding the above-mentioned rough cloth, open-width water washing is carried out at a temperature of 40°C and a vehicle speed of 20 m / min.

[0046] 2) Pre-setting process: 1) The rough cloth after the open-width washing operation is passed through a knitted fabric setting machine (Wuxi Xindu Printing and Dyeing Machinery Co., Ltd.), at 170°C, with an overfeed of 30%, and a speed of 15 m / min. Perform the setting operati...

Embodiment 3

[0049] Embodiment 3: a kind of processing method of polyester spandex, tencel knitted color strip fabric of short process, is made up of following steps:

[0050] The short-process polyester spandex and tencel knitted color striped fabric provided in this embodiment is a colored striped fabric obtained by knitting polyester spandex fibers and tencel fibers through a knitting method as a rough cloth.

[0051] The disperse dye that the colored stripe fabric of this implementation adopts is disperse blue 102.

[0052] 1) Open-width water washing process: After unwinding the above-mentioned rough cloth, open-width water washing is carried out at a temperature of 80°C and a vehicle speed of 15 m / min.

[0053] 2) Pre-setting process: 1) The rough cloth after the open-width washing operation is passed through a knitted fabric setting machine (Wuxi Xindu Printing and Dyeing Machinery Co., Ltd.), at 185°C, with an overfeed of 50%, and a speed of 30 m / min. Perform the setting operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com