Water purification machine using hydrodynamic effluent pressurization increment device

A water purifier and water-using technology, applied in the field of water purifiers, can solve the problems of increasing gas supplementation work and after-sales service costs, inability to integrate, and limited pure water storage, so as to save gas supplementation work and after-sales service costs, The effect of increasing water storage capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

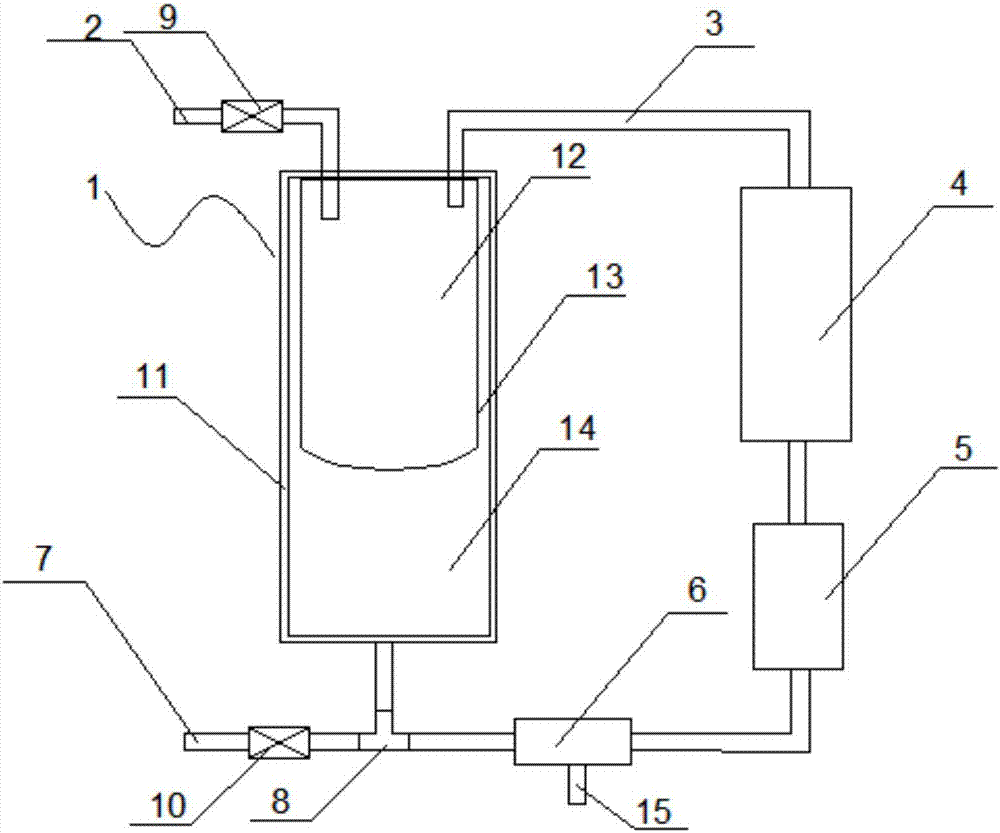

[0021] The present invention provides a pure water machine using a water-driven water pressurizing and increasing device, which includes a water-driven water pressurizing and increasing device 1, a multi-stage filtering system 4 and a water pump 5. The water-driven water pressurizing and increasing device 1 includes The sealed cylinder 11 and the inner liner 13 are separated by the inner liner 13 into a tap water storage cavity 12 and a pure water storage cavity 14. The inner liner 13 is made of an elastic material. The elastic material is silica gel and is separated by silica gel. It has a good elastic effect, realizes the change in the size of the tap water storage cavity 12 and the pure water storage cavity 14, and will not have any influence on the taste of pure water, and will not cause secondary pollution.

[0022] The tap water storage cavity 12 is connected to the tap water inlet 2 through the connecting pipe 3, the tap water storage cavity 12 is connected to the water inl...

Embodiment 2

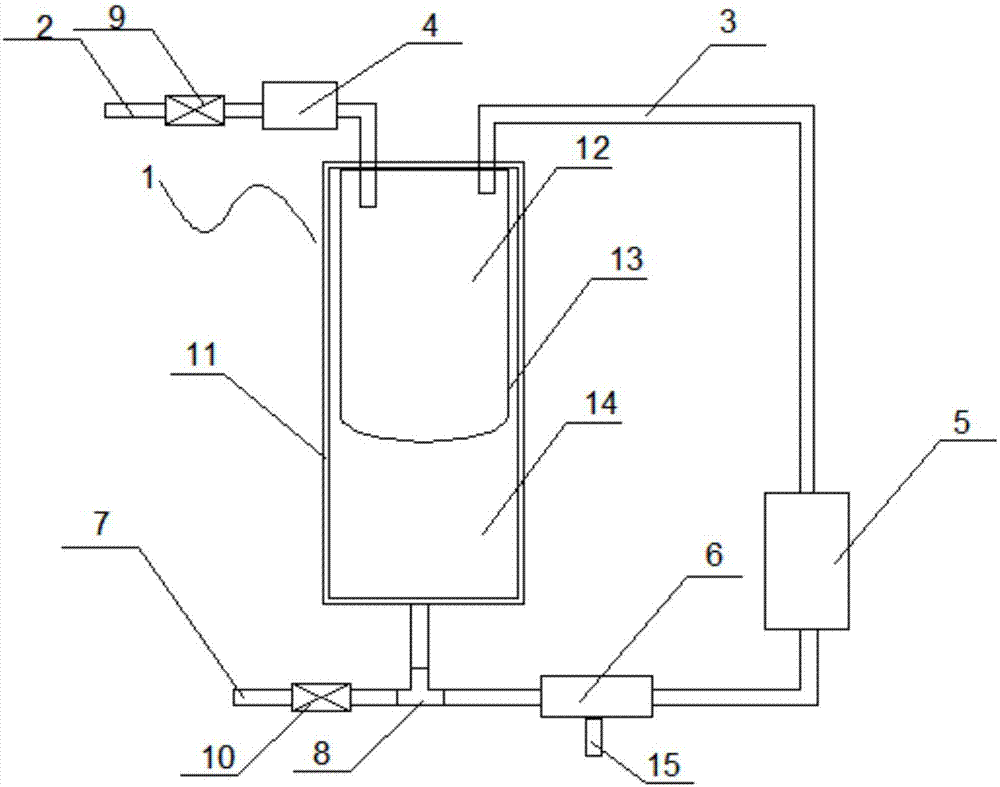

[0030] The difference between this embodiment and embodiment 1 lies in figure 2 As shown, the three-stage filtration system is provided at the water inlet end of the tap water storage cavity 12.

[0031] The other structure of this embodiment is the same as that of Embodiment 1, and no specific description will be made in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com